We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

-

1.Overview

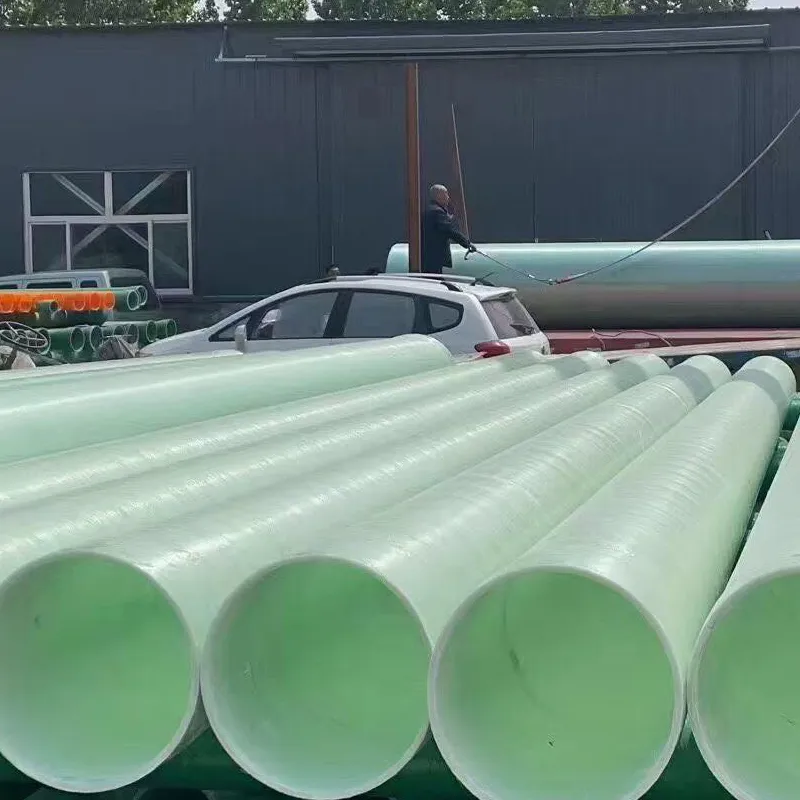

FRP (Fiberglass Reinforced Plastic) Pipes are composite pipes made of glass fiber reinforcements embedded in a thermosetting resin matrix (e.g., epoxy, polyester, or vinyl ester). They combine high strength, corrosion resistance, and lightweight properties, making them ideal for aggressive environments in industries such as chemical processing, water treatment, and offshore engineering.

-

2.Structure & Manufacturing

2.1 Layered Composition

Layer Material/Function Inner Liner Resin-rich layer with additives (e.g., graphite) for corrosion/abrasion resistance. Structural LayerGlass fiber + resin matrix (filament winding or centrifugal casting) for mechanical strength. Outer Layer UV-resistant resin or gel coat for environmental protection.

2.2 Manufacturing Processes

Filament Winding: Continuous fibers wound at precise angles (for high-pressure applications).

Centrifugal Casting: Uniform wall thickness, suitable for large-diameter pipes.

Pultrusion: Continuous production of standard profiles (e.g., small-diameter pipes).

-

3.Key Advantages

Feature|Benefit Corrosion ResistanceResists acids, alkalis, salts, and solvents (pH range: 2–12). High Strength-to-Weight 1/4 the weight of steel with comparable tensile strength (≥250 MPa). Low Maintenance No cathodic protection required; lifespan ≥50 years in harsh environments. Smooth Interior Low friction loss (Hazen-Williams C-factor: 150 vs. 100 for steel). Thermal Insulation Low thermal conductivity (0.04 W/m·K), reducing heat loss/gain.

4. Technical Specifications

4.1 Standard Parameters

Diameter Range: DN 25 – DN 4000 (1" – 157").

Pressure Rating: PN 6 – PN 25 (customizable to PN 40).

Temperature Range: -40°C to 120°C (epoxy resin); up to 180°C (special resins).

4.2 Connection Methods

Flanged Joints: ANSI/ASME B16.5 or DIN standards.

Bell & Spigot: Rubber gasket-sealed for leak-free assembly.

Threaded/Coupled: For small-diameter industrial piping.

-

5.Applications

Industry Use CaseChemical Processing Transfer of HCl, H₂SO₄, chlor-alkali solutions. Water & Wastewater Sewage lines, desalination plants, cooling water systems.Oil & Gas Offshore brine injection lines, firewater systems. Power Generation FGD (Flue Gas Desulfurization) systems, ash handling.

-

6.Standards & Certifications

ASTM D2996: Filament-wound FRP pipes.

ISO 14692: FRP piping for petroleum/natural gas industries.

AWWA C950: Water transmission and distribution.

-EN 14364: Underground drainage and sewerage.

-

7.Comparison with Other Materials

Parameter FRP Steel PVC Corrosion Resistance Excellent Poor (requires coating) Good (limited to mild chemicals) Weight 1.8 g/cm³ 7.8 g/cm³ 1.4 g/cm³ Installation Cost Low (no welding needed) High (labor + coating) Moderate Lifespan 50+ years 15–25 years 20–30 years **8. Installation & Maintenance Handling Use nylon slings to avoid surface damage; no heavy machinery required.

Support Spacing :

DN 100: 2.5–3.0 m

DN 500: 4.0–5.0 m

Inspection : Annual checks for surface cracks or joint leaks; ultrasonic testing for critical systems.

8. Cost Considerations

Initial Cost: 20–50% higher than PVC, but 30–60% lower than stainless steel.

Lifecycle Cost: 40–70% savings over 20 years due to minimal maintenance.

9. Leading Manufacturers

Ameron International (U.S.): Specialty in Bondstrand® FRP pipes.

Hobas (Switzerland): CC-GRP pipes for large-diameter applications.

Sekisui Chemical (Japan): High-pressure FRP systems.

Conclusion

FRP pipes offer unmatched corrosion resistance, longevity, and cost efficiency for demanding industrial applications. When specifying FRP, prioritize resin compatibility with the service fluid, validate pressure/temperature ratings, and adhere to ASTM/ISO standards. For custom projects (e.g., high-temperature lines), consult manufacturers for resin optimization and joint design.

For detailed quotes or technical datasheets, provide operational parameters (fluid type, temperature, pressure) and project specifications.

What Our Customers Say About FRP Pipe

FRP Pipe FAQ

-

Q: What is an FRP pipe?

A: An FRP pipe is a lightweight, corrosion-resistant pipe made from fiberglass reinforced plastic, used for transporting liquids and gases.

-

Q: What are the main advantages of FRP pipes?

A: FRP pipes offer excellent resistance to chemicals, corrosion, and high temperatures, making them ideal for harsh industrial environments.

-

Q: Where are FRP pipes typically used?

A: They are used in water treatment, chemical processing, and agriculture for fluid transportation.

-

Q: How do FRP pipes compare to metal pipes?

A: FRP pipes are more resistant to corrosion, require less maintenance, and are lighter than metal pipes, offering long-term cost savings.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China