We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Air Conditioning Cooling Tower Technical Introduction

-

1.Overview

An air conditioning cooling tower is a critical heat rejection component in central HVAC systems, designed to dissipate waste heat from condensers into the atmosphere via evaporative cooling. It ensures efficient operation of refrigeration cycles and is widely used in commercial buildings (e.g., offices, hospitals, hotels) and industrial facilities (e.g., data centers). Key design considerations include chiller capacity, ambient wet-bulb temperature, and spatial constraints.

2. Working Principle

-

Hot Water Inlet: Hot water (typically 37°C) from the chiller condenser enters the cooling tower.

-

Water Distribution: Spray nozzles evenly distribute water over the fill media.

-

Air-Water Heat Exchange: Fans drive air to interact with water in counterflow or crossflow configurations, enabling evaporative cooling.

-

Cooled Water Return: Chilled water (≈32°C) recirculates to the condenser.

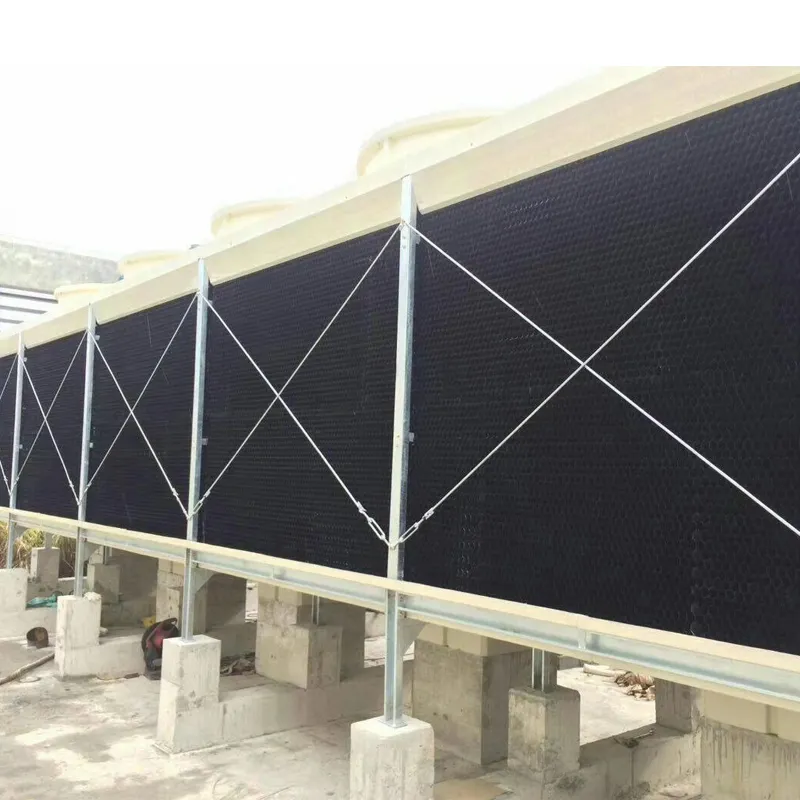

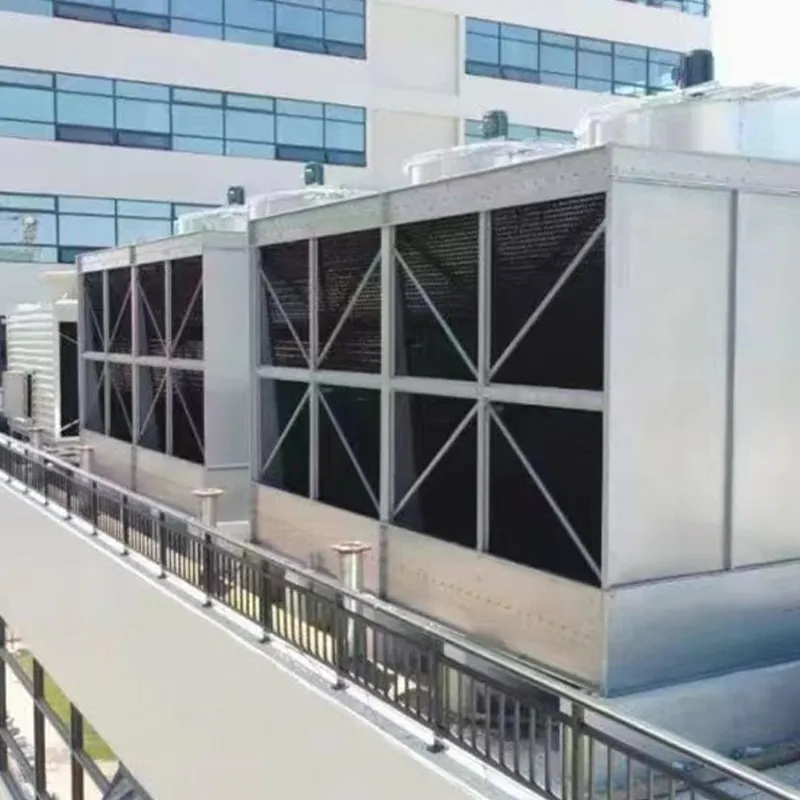

3. Types of Cooling Towers

4. Key Components & Design

4.1 Core Components

Fill Media: PVC or PP modules to maximize air-water contact area.

Fan System: Axial/centrifugal fans (e.g., 7.5 kW motor for a 100 TR tower).

Water Distribution: Rotary nozzles or fixed spray pipes.

-Drift Eliminator: Reduces water loss (<0.001% drift rate).

Casing: FRP (corrosion-resistant) or galvanized steel (cost-effective).

4.2 Design Parameters

Cooling Capacity (TR): 1 TR = 3.516 kW; tower capacity = 1.2–1.3× chiller TR (to offset heat loss).

Wet-Bulb Temperature (WBT): Critical design baseline (e.g., 28°C).

-

Approach: Temperature difference between cooled water and WBT (typically 3–5°C).

5. Selection & Configuration Guidelines

5.1 Sizing Formula

Tower Water Flow (m³/h) = \[ Chiller Capacity (TR) × 3024 × 1.3 \] ÷ 5000

Example: For a 500 TR chiller → ≈393 m³/h.

6. Energy Efficiency & Sustainability

Energy-Saving Technologies:

Variable Frequency Drives (VFDs) reduce fan power by 20–30%.

High-efficiency fill media (15% higher heat transfer).

Eco-Friendly Features:

FRP compatible with low-GWP refrigerants (e.g., R-1233zd).

Noise control ≤65 dB(A) @ 1m (ASHRAE compliant).

7. Maintenance & Troubleshooting

Routine Maintenance:

Weekly: Check water level/pH (6.5–8.5).

Monthly: Clean fill media and filters.

Common Issues:

Reduced Efficiency: Clogged fills or fan imbalance.

Abnormal Noise: Bearing wear or loose blades.

8. Typical Applications

Commercial Buildings: Malls, offices (200–1,000 TR towers).

Data Centers: Redundant N+1 configurations.

Healthcare Facilities: Closed-loop towers for contamination control.

9. Cost Reference (RMB)

|

Capacity (TR) |

Price Range (10,000 RMB) |

Remarks |

|

100 TR |

8–15 |

FRP counterflow, standard config. |

|

500 TR |

40–70 |

VFD fans + smart controls. |

|

1,000 TR |

80–150 |

Modular design for parallel setups. |

10. International Standards & Certifications

ASHRAE 90.1: Energy efficiency requirements.

EN 13053: Ventilation system compliance (EU).

LEED Certification: Credits for water/energy conservation.

Conclusion

Air conditioning cooling towers are vital for HVAC system efficiency. Counterflow towers suit high-performance commercial buildings, while crossflow models excel in space-limited retrofits. Prioritize smart monitoring systems (IoT-enabled) and align designs with local WBT and sustainability goals.

For brand recommendations (e.g., BAC, SPX, EVAPCO) or detailed technical comparisons, specify your project requirements (climate zone, budget, etc.).

What Our Customers Say About Air Conditioning Cooling Tower

Air Conditioning Cooling Tower FAQ

-

Q: What is an air conditioning cooling tower?

A: An air conditioning cooling tower is designed to expel excess heat from air conditioning systems, ensuring efficient cooling performance.

-

Q: Where are air conditioning cooling towers typically used?

A: These towers are used in large buildings, commercial complexes, and industrial facilities with central air conditioning systems.

-

Q: What are the advantages of using an air conditioning cooling tower?

A: They improve energy efficiency, reduce operational costs, and extend the lifespan of HVAC systems.

-

Q: How does an air conditioning cooling tower help with HVAC system performance?

A: By efficiently rejecting heat, they ensure that air conditioning systems operate at optimal capacity, even under high cooling demands.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China