We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

- 1.Overview

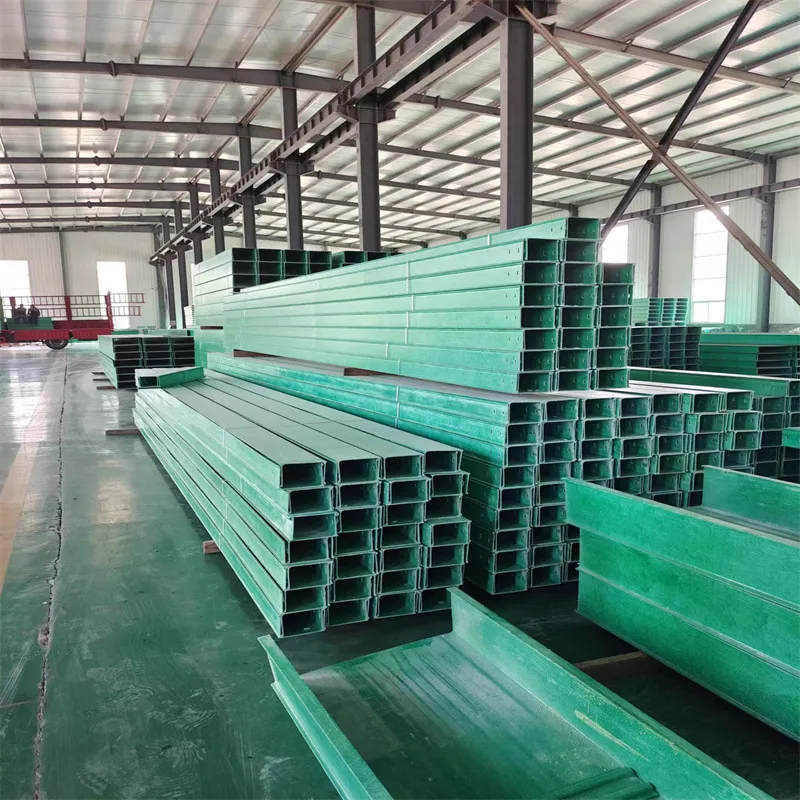

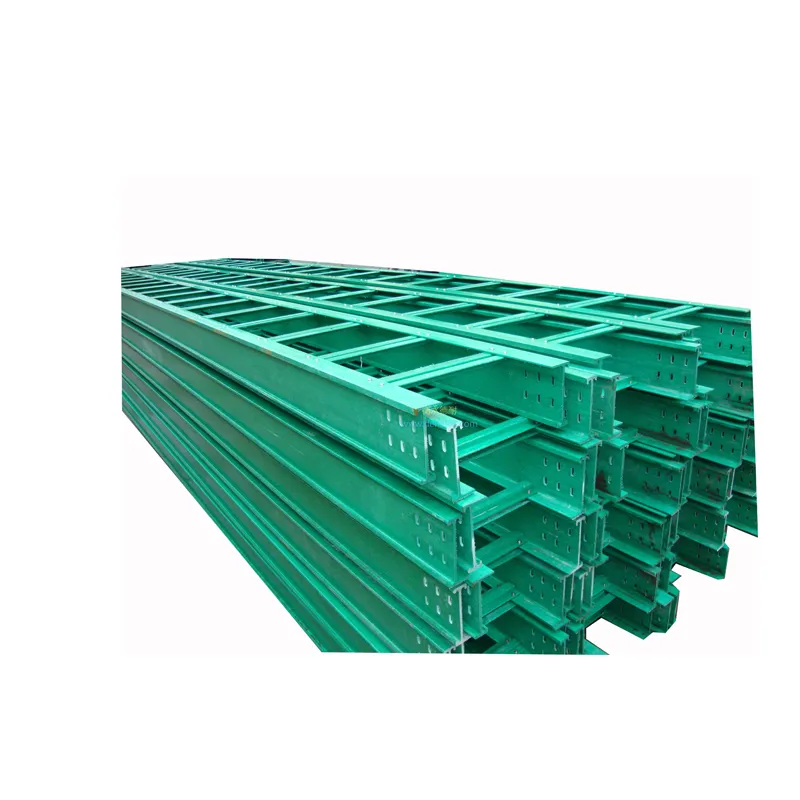

FRP Cable Bridges/Trays are structural support systems designed for organizing and protecting electrical or communication cables in industrial, commercial, and infrastructure projects. Made from glass fiber-reinforced polymer (FRP), they combine lightweight properties with high mechanical strength and corrosion resistance, making them ideal for harsh environments such as chemical plants, coastal areas, and underground installations.

2.Material & Structural Design

2.1 Composition

Core Material: Glass fibers embedded in a thermosetting resin matrix (e.g., polyester, vinyl ester) for enhanced durability.

Surface Treatment: UV-resistant coatings to prevent degradation from sunlight exposure.

2.2 Key Features

Lightweight: 1/4 the weight of steel trays, reducing installation labor and structural load.

High Strength-to-Weight Ratio: Tensile strength comparable to steel (≥250 MPa) with superior impact resistance.

Corrosion Resistance: Immune to rust, acids, alkalis, and saltwater, suitable for pH 2–12 environments.

Electrical Insulation: Non-conductive, preventing electromagnetic interference and enhancing safety.

3. Applications

FRP cable trays are widely used in:

Industrial Facilities: Chemical plants, oil refineries, and power stations where corrosive fumes or moisture are present.

Infrastructure Projects: Subways, airports (e.g., Beijing New Airport), and bridges requiring long-term durability.

Telecommunications: Data centers and communication hubs for organizing fiber optic cables.

Renewable Energy: Solar farms and offshore wind turbines exposed to salty or humid conditions.

4. Advantages Over Traditional Materials

| Parameter | FRP Cable Trays | Steel Trays | Plastic Trays |

| Weight | 1.8–2.0 g/cm³ | 7.8 g/cm³ | 1.2–1.4 g/cm³ |

| Corrosion Resistance | Excellent (no coating required) | Moderate (limited chemical resistance) | Poor (requires galvanization) |

| Installation Cost | Low (modular design) | High (welding + coating) | Moderate |

| Lifespan | 30+ years | 10–15 years | 10–20 years |

| Maintenance | Minimal (no rust removal) | Frequent (anti-corrosion) | Moderate (UV degradation) |

Source: Comparative analysis from industrial applications.

5. Installation & Maintenance Guidelines

5.1 Installation

- Site Preparation: Measure and mark cable routes, ensuring proper alignment and load-bearing capacity.

- Modular Assembly: Connect FRP sections using corrosion-resistant bolts or clamps.

- Support Spacing:

For standard loads: 1.5–3.0 meters (varies with tray width and cable weight).

For heavy-duty loads: Reduce spacing or use reinforced brackets.

5.2 Maintenance

Routine Checks: Inspect for surface cracks or debris accumulation quarterly.

Cleaning: Use non-abrasive cleaners to avoid damaging the resin surface.

6. Standards & Certifications

ASTM D5364: Standard for FRP grating systems.

NEMA VE-1: Cable tray performance requirements.

ISO 14692: FRP applications in corrosive environments.

7. Industry Case Study

Beijing New Airport: FRP cable trays were deployed to manage electrical systems, leveraging their lightweight and corrosion-resistant properties to ensure long-term reliability in high-humidity conditions.

8. Leading Manufacturers

Ameron International: Specializes in high-performance FRP solutions for industrial use.

Bedford Reinforced Plastics: Customizable FRP trays for large-scale infrastructure.

Conclusion

FRP cable bridges/trays offer unmatched durability, safety, and cost efficiency for modern cable management needs. Their corrosion resistance and lightweight design make them indispensable in harsh environments, outperforming traditional steel and plastic alternatives. For optimal performance, adhere to installation guidelines and prioritize manufacturers with ISO/ASTM certifications.

For detailed specifications or project-specific quotes, provide parameters such as tray dimensions, load requirements, and environmental conditions.

What Our Customers Say About FRP Cable Bridge

Frp Cable Bridge FAQ

-

Q: What is an FRP cable bridge?

A: An FRP cable bridge is a structural solution made from fiberglass reinforced plastic, used to support and protect electrical cables.

-

Q: Why use FRP for cable bridges?

A: FRP offers high strength, corrosion resistance, and is lightweight, ensuring long-term durability and reduced maintenance.

-

Q: Where are FRP cable bridges typically used?

A: They are used in power plants, industrial facilities, and large-scale construction projects to organize and protect cables.

-

Q: What are the maintenance requirements for an FRP cable bridge?

A: FRP cable bridges require minimal maintenance, mainly periodic inspections to ensure proper cable support and protection.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China