We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Here’s a professional English introduction to FRP (Fiberglass Reinforced Plastic) Grating, incorporating technical specifications, applications, advantages, and market insights from the provided search results:

FRP Grating Technical Introduction

- 1.Overview

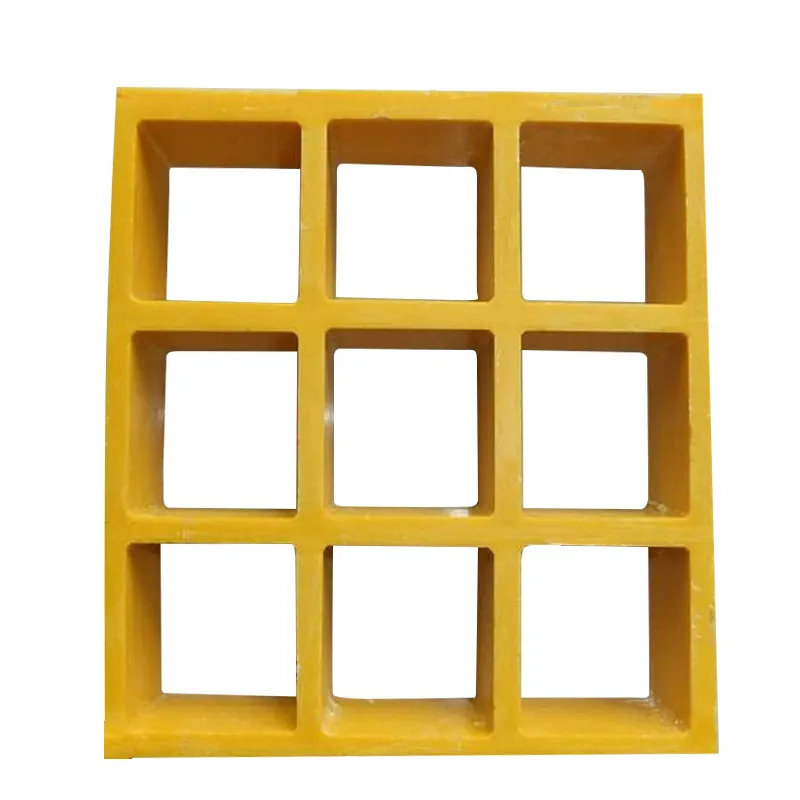

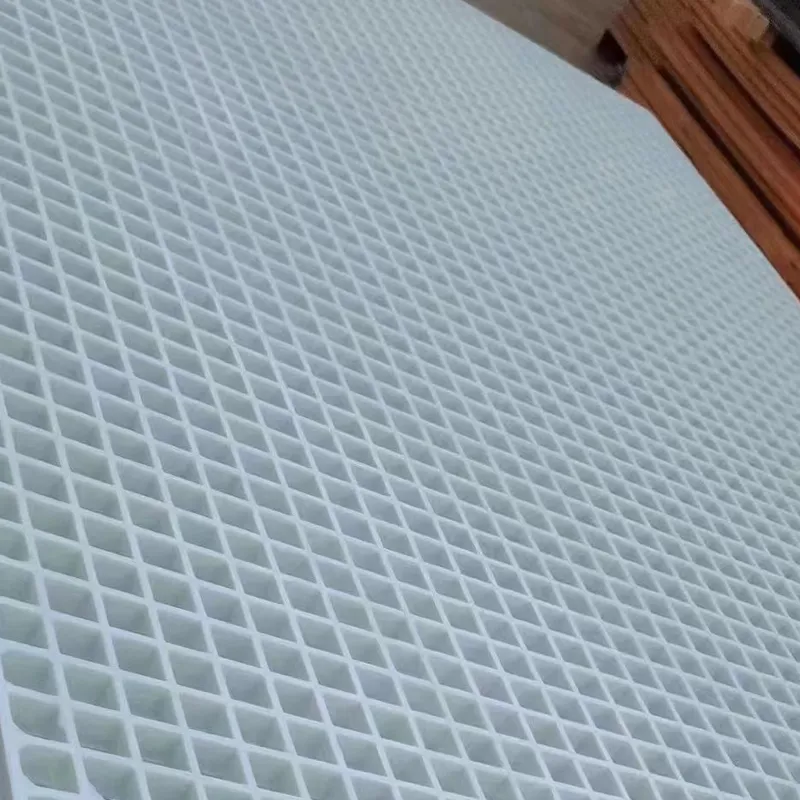

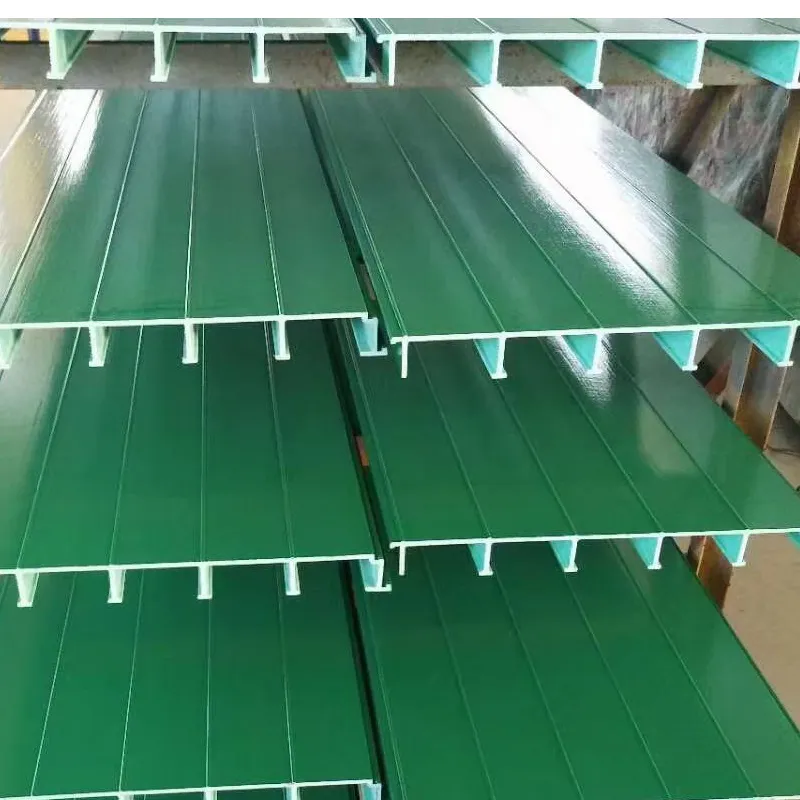

FRP Grating is a composite material made by combining glass fiber reinforcements with a thermosetting resin matrix (e.g., polyester, vinyl ester, or phenolic). It is widely used in industrial, marine, and infrastructure projects due to its unique properties, including corrosion resistance, high strength-to-weight ratio, and electrical insulation. FRP grating is manufactured through two primary processes: molded (hand-layered) and pultruded (continuous fiber alignment), each offering distinct structural benefits.

2. Material & Manufacturing

2.1 Composition

Core Materials:

Glass Fibers: Provide tensile strength and structural integrity.

Resins: Polyester (most common), vinyl ester (for enhanced corrosion resistance), or phenolic (fire-retardant).

Surface Treatments: UV-resistant coatings or gritted surfaces for anti-slip properties.

2.2 Manufacturing Processes

| Process | Key Features | Applications |

| Molded Grating | Hand-layered fibers create bi-directional strength; customizable mesh sizes (e.g., 38×38 mm or 50×50 mm). | Walkways, stair treads, platforms. |

| Pultruded Grating | Continuous fibers aligned for unidirectional strength; ideal for long spans and heavy loads. | Bridges, cooling towers, modular structures. |

3. Key Properties

| Property | Advantage |

| Corrosion Resistance | Resists acids, alkalis, and saltwater (pH 2–12), ideal for chemical plants and marine environments. |

| Lightweight | 1/4 the weight of steel, reducing installation costs and structural load. |

| Electrical Insulation | Non-conductive, safe for use near high-voltage equipment. |

| Low Maintenance | No rust, coatings, or frequent repairs required; lifespan exceeds 30 years. |

| Fire Retardancy | Phenolic resin variants meet fire safety standards (e.g., ASTM E84). |

4. Applications

| Industry | Use Cases |

| Industrial | Petrochemical platforms, mining walkways, food processing floors. |

| Water Management | Wastewater treatment grids, drainage covers. |

| Marine | Dock platforms, offshore oil rigs, shipbuilding. |

| Infrastructure | Cooling tower walkways, highway guardrails, safety fences. |

| Energy | Solar farm structures, power plant grating. |

5. Comparison with Traditional Materials

| Parameter | FRP Grating | Steel Grating | Wooden Planks |

| Weight | 1.8–2.0 g/cm³ | 7.8 g/cm³ | 0.5–0.8 g/cm³ |

| Corrosion Resistance | Excellent (no coatings needed) | Poor (requires galvanization) | Poor (rots in moisture) | |

| Installation Cost | Low (modular, no welding) | | High (labor-intensive) | Moderate |

| Lifespan | 30+ years | 15–25 years | 5–10 years |

6. Market Insights

Global Market Size: Projected to reach USD 574.2 million by 2021, growing at a CAGR of 4.24%.

Key Drivers: Demand from water treatment, oil & gas, and renewable energy sectors.

Regional Growth: Asia-Pacific dominates due to industrialization in China and India.

Challenges: Higher initial costs compared to steel; competition from low-cost alternatives.

7. Leading Manufacturers

- Strongwell Corporation (U.S.): Specializes in pultruded grating for heavy-load applications.

- Shirui Composites (China): Offers ISO 9001-certified molded and pultruded grating, exported globally.

- Bedford Reinforced Plastics (U.S.): Customizable solutions for industrial and marine sectors.

- Kemrock Industries (India): Focuses on cost-effective grating for emerging markets.

8. Standards & Certifications

ASTM D5364: Performance standards for FRP grating.

EN 124: Certification for drainage covers.

SGS/DNV/ABS: International quality assurance for marine and industrial use.

9. Installation & Maintenance Tips

Foundation: Ensure flat surfaces with adequate support spacing (1.5–3.0 m for standard loads).

Fastening: Use corrosion-resistant bolts or clamps for modular assembly.

Cleaning: Rinse with water or mild detergent to prevent debris buildup.

10. Future Trends

Smart Grating: Integration with IoT sensors for structural health monitoring.

Sustainable Materials: Increased use of recycled resins and bio-based fibers.

Conclusion

FRP grating is a versatile, durable solution for modern industrial and infrastructure needs. Its corrosion resistance, lightweight design, and low lifecycle costs make it superior to traditional materials like steel or wood. For optimal performance, select the appropriate resin type (e.g., vinyl ester for harsh chemicals) and manufacturing process (molded for bidirectional strength or pultruded for long spans). With Asia-Pacific leading market growth, FRP grating is poised to revolutionize sectors from water management to renewable energy.

For custom solutions or detailed specifications, consult manufacturers like Shirui Composites or Strongwell Corporation, leveraging their expertise in tailored designs and international certifications.

What Our Customers Say About FRP Grating

FRP Grating FAQ

-

Q: What is FRP grating?

A: FRP grating is a flooring material made from fiberglass reinforced plastic, known for its strength, slip resistance, and corrosion resistance.

-

Q: What are the benefits of using FRP grating?

A: FRP grating provides durability, safety with slip resistance, and is lightweight, making it ideal for industrial environments.

-

Q: Where is FRP grating commonly used?

A: It’s commonly used for walkways, platforms, drainage covers, and in chemical and oil refineries.

-

Q: How does FRP grating improve safety in industrial environments?

A: Its slip-resistant surface reduces the risk of accidents, and its high strength ensures it can handle heavy loads in industrial areas.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China