We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Aug . 02, 2025 12:40

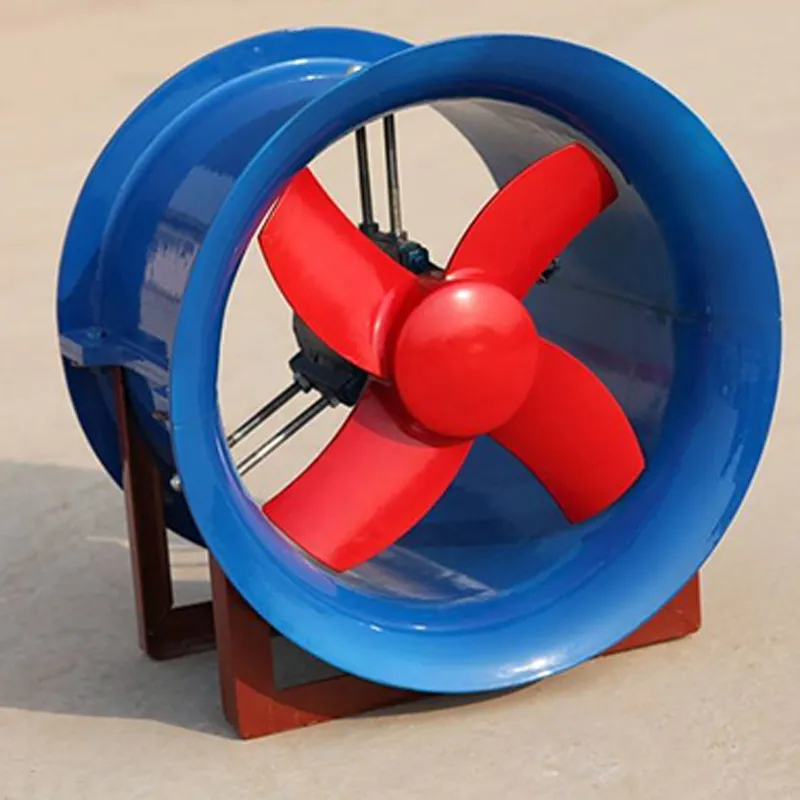

Discover axial flow fan for sale solutions engineered for industrial excellence. Explore market trends, compare leading axial and centrifugal fans, dig into detailed specifications, and learn why FRP technology sets new standards for energy efficiency and corrosion resistance.

1. Axial Flow Fan Industry Overview & Market Trends

Market Size (2023): Global industrial ventilation equipment market: USD 6.5 billion

Growth Rate (CAGR): Projected 5.7% (2024-2029)

Main Drivers: Increasing demand in petrochemical, metallurgy, HVAC, water treatment, and tunnel projects.

Axial flow fans remain the backbone of industrial and commercial ventilation due to their compact structure, high airflow rates, modular installation, and efficiency. Compared with centrifugal fans, axial fans excel in:

Growth Rate (CAGR): Projected 5.7% (2024-2029)

Main Drivers: Increasing demand in petrochemical, metallurgy, HVAC, water treatment, and tunnel projects.

Axial flow fans remain the backbone of industrial and commercial ventilation due to their compact structure, high airflow rates, modular installation, and efficiency. Compared with centrifugal fans, axial fans excel in:

- High volume, low pressure airflow delivery

- Low energy consumption

- Flexible mounting: wall, duct, portable

- Wide application: process cooling, exhaust/vent, air handling, gas transport

2. Technical Parameters & Comparative Table

Before selecting any axial flow fan for sale, technical data review is essential. See below for key comparative parameters for axial and centrifugal fans, as found in the latest supplier catalogs and ISO application standards (ISO 5801 / ISO 13349 / ANSI/AMCA 210):

| Parameter | FRP Axial Flow Fan | Stainless Steel Axial | Centrifugal Fan |

|---|---|---|---|

| Air Flow (m³/h) | 4,000 – 250,000 | 3,000 – 200,000 | 2,500 – 180,000 |

| Pressure (Pa) | 80 – 2200 | 60 – 2100 | 150 – 8000 |

| Power (kW) | 1.5 – 90 | 1.1 – 75 | 2.2 – 110 |

| Efficiency (%) | 72 ~ 88 | 68 ~ 84 | 65 ~ 85 |

| Material | FRP/PP/Steel Core | AISI 304/316 | Carbon Steel/SS/Aluminum |

| Noise dB(A) | ≤82 | ≤85 | ≤92 |

| Corrosion Resistance | Excellent | Good | Average |

| Typical Lifecycle | ≥15 yrs | 7-10 yrs | 5-8 yrs |

Technical Index Comparison: Axial vs. Centrifugal Fans

3. Frp Axial Flow Fan: Product Specifications & Construction

- Model: 4-72, 9-19, DWT, Customizable

- Air Flow Rate: 4,000 ~ 250,000 m³/h

- Static Pressure: 80 ~ 2200 Pa

- Impeller Diameter: 350 – 1500 mm

- Blade Material: FRP with glass-fiber enhancement

- Motor Power: 1.5 – 90 kW, IE3/IE4 efficient standards

- Bearing & Shaft: SKF/NSK, anti-rust sealed

- Certifications: ISO 9001, ISO 14001, AMCA 210, CE, SGS

- Temperature Range: -40°C ~ +70°C (special up to +120°C)

- Corrosive Media: Adapted for H2SO4, HCL, Cl2 gas, saline mist

- Typical Application: Chemical exhaust, acid/alkali workshop, water treatment, power plant

Product Lifecycle Distribution

4. Crafting the Perfect Axial Flow Fan for Sale: Process Flow & Quality Assurance

- Step 1. Raw Material Selection

Strict incoming inspection of FRP roving, gelcoat, resins; compliance with ISO 9001 traceability records. - Step 2. Impeller Molding

Multi-layer glass fiber hand lay-up, vacuum infusion; CNC trimming for aerodynamic precision. - Step 3. Shell & Support Fabrication

Molds for cylindrical case and mounting flanges designed for ISO tolerance grades; joints reinforced. - Step 4. Machining & Assembly

Shaft precision: ISO h6/h7 tolerance; bearing chamber CNC boring; dynamic balance to G2.5 (per ISO 1940). - Step 5. Surface Protection

UV resistant gelcoat, flame-retardant / antistatic options as per customer process conditions. - Step 6. Rigorous Testing

AMCA/ISO performance test stand:- Flow & pressure curve mapping (ISO 13350 method)

- Vibration, noise ≤ 82dBA at 1m (EPA/OSHA standard)

- Corrosion resistance (ASTM B117 1000h salt spray)

- Step 7. Packing & Delivery

Shock-proof crate, moisture & impact protection; each fan has unique QR for traceability.

Axial fan production flow – click for video demo

5. Main Advantages of FRP Axial Flow Fan

- Corrosion Proof: Adapted to acid, alkali, chloride, nitric, ammonia vapors; outperforms steel/aluminum in harsh process gas.

- High Efficiency Impeller: Streamlined, optimized by CFD; up to 88% measured per ISO 13350.

- Low Weight & Flexible Mounting: 40% lighter than steel design, reduces civil foundation/infrastructure cost.

- Noise Control: Anti-vibration bearing seat & direct-drive minimize transmission noise; ≤82dBA for standard.

- Custom Solutions: Defined by real operating conditions (corrosive gases, high humidity, explosive gas zone).

- Extended Lifecycle: Typical MTBF exceeds 60,000 hours; minimal downtime.

Energy Efficiency Trends (Reference to ANSI/AMCA 210 Test Results)

6. Manufacturer & Supplier Comparison

| Brand / axial fan manufacturers | Country/Region | Main Strengths | Certifications |

|---|---|---|---|

| LONGXUAN (FRP Specialist) | China | Custom FRP, full process quality traceability, anti-corrosion focus, 100+ export countries | ISO 9001, SGS, CE |

| Twin City Fan | USA | Large-scale, standard and custom solutions, industrial HVAC | AMCA, ISO 9001 |

| Ziehl-Abegg | Germany | High-precision, noise reduction, EC drives | ISO 9001, ISO 14001 |

| Greenheck | USA | Complete axial and centrifugal fans, global tech support | AMCA, ISO 9001 |

| FAWENT | Poland | Industrial fans, energy sector focus | ISO, CE |

7. FRP Customization Solutions & Service Process

- Requirement Analysis: Airflow, pressure, corrosive media, dimension, connection standard consultation.

- Proposal & 3D Design: CFD optimization, GA drawing, CAD & 3D model review with customer.

- Sample/Batch Production: Pre-serial prototype, ISO/AMCA flow and pressure validation; iterative improvement.

- Packing & Logistics: Export-grade packaging, real time GPS tracking, CE/EAC/SGS documentation.

- Commissioning & Maintenance: On-site startup, vibration/noise check, operator training, warranty kick-off.

8. Application Cases: Industry Excellence in Action

- Petrochemical Plant, Middle East (2023): 32 sets of axial flow fan for sale (FRP type) for acid exhaust. Efficiency >85%, site-reported vibration & noise reduction by 23% compared to legacy steel fans.

- Municipal Wastewater Treatment (Vietnam, 2022): 18 units, highly corrosive, 7-year zero corrosion claim by operator.

- Metallurgical Fume Extraction (Russia, 2021): Custom blade profile for dust, anti-abrasive coating, 36-month continuous operation without significant wear.

- Tunnel Ventilation, Urban Metro: Stainless+FRP hybrid for fire/gas resistance, airflow up to 210,000 m³/h, integration with auto control.

“After 18 months, amp draw and vibration have held stable, and maintenance intervals cut by over 60%. The FRP axial solution is a game changer for durability in acid gas exhausting.”

- Site Chief Engineer, Middle East Oil Refinery

FAQ: Professional FAQ on Axial Flow Fan Materials, Specs & Standards

- Q1: What are the main material advantages of FRP in axial flow fans for sale?

- A1: FRP offers superior chemical and saltwater resistance, low mass, and high mechanical strength. Blades maintain dimensional stability at temperatures up to +120°C and in aggressive industrial atmospheres, as tested per ASTM D543 and ISO 175.

- Q2: How precise are the impeller and housing tolerances?

- A2: Blade and shaft tolerances are held to ISO h6-h7, impeller assembly balance per ISO 1940 G2.5 (residual vibration

- Q3: What certifications should top axial fan manufacturers possess?

- A3: Leading manufacturers comply with ISO 9001/14001, and third-party tested to AMCA 210, CE (Europe), SGS (global), as well as local electrical/ATEX standards for hazardous gas zones.

- Q4: Can axial centrifugal fan designs be customized for both high pressure and high flow?

- A4: Yes, combi-series and mixed-flow designs (bridging axial & centrifugal characteristics) allow customization for unique process needs, especially when balancing energy, flow curve, and installation footprint.

- Q5: Are there standard connections and flange interfaces?

- A5: Yes. According to ISO 13351, ANSI/ASME/EN flange drilling can be specified, and flexible/rigid mounts are supported.

- Q6: What is the industry norm for testing and acceptance?

- A6: Functional tests per ISO 5801 (performance), AMCA 210 (airflow/pressure), ISO 1940 (balancing), and ASTM B117 (corrosion/salt spray) certify each fan prior to shipment.

- Q7: What are typical industrial axial fan price determinants?

- A7: Key factors are material (FRP vs. SS), air volume/pressure, drive type, coatings, certifications, and order volume. FRP fans are 20-30% more cost-effective lifecycle-wise for corrosive applications due to reduced maintenance.

9. Ordering, Delivery, Warranty & Customer Support

- Lead Time: Standard models: 10–22 working days, custom: 3–7 weeks (EXW/FOB/CIF available)

- Payment Terms: T/T, L/C, trade assurance

- Warranty: 24 months full mechanical & material warranty, 60,000h+ bearing MTBF, lifetime technical support

- Support: 24/7 hotline, remote diagnostics, spare parts in-stock, global service network

Ready to upgrade your ventilation system? Choose axial flow fan for sale from certified experts. Contact us for a custom offer.

References & Further Reading:

- AMCA International. (2023). “AMCA 210 Laboratory Test Standard for Fans” https://www.amca.org

- ISO. “ISO 5801: Performance Testing of Fans”. https://www.iso.org/standard/5073.html

- Fan Engineering – Buffalo Forge Company (industry classic): https://www.fancentral.com/fan-engineering/

- Chemical Engineering Forum: https://www.cheresources.com/invision/forum/17-equipment/

- ASHRAE Journal, “Corrosion-resistant Fans for Industrial Ventilation, 2022” ASHRAE

Resources

Products

Can't Find The Products And Services You Need?

If you need our help,

Our staff will be happy to help and answer your questions!

Factory Processing

The factory processes raw materials into finished products using advanced machinery and skilled labor.

Build Synergy

We provide collaborative services tailored to client needs, ensuring seamless communication and mutual growth.

Global Supply

Our innovative products are bestsellers worldwide, celebrated for their exceptional quality, reliability, and global appeal.

Global Supply

We ensure consistent product availability through a reliable and efficient global supply network.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China