We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Evaporative Condenser technology has fundamentally reshaped the landscape of industrial heat exchange by providing outstanding energy efficiency, corrosion resistance, and lifecycle economy for modern industries. This in-depth guide explores Evaporative Condenser solutions by analyzing industry trends, technical specifications, manufacturing process, application cases, and a detailed supplier comparison. Data-driven, authoritative, and standards-oriented, this document is tailored to professionals and procurement decision-makers across petrochemical, metallurgy, HVAC, cooling, and process engineering sectors.

1. Global Industry Trend Analysis (2024)

Projected CAGR (2023-2029): 6.7% (Source)

Key Growth Drivers: Stringent energy efficiency standards (ISO 50001), expansion in cold chain logistics, growing needs in petrochemical, pharmaceutical, metallurgy, and district cooling projects.

Market Dynamics & Forecasts

- 2023 Asia-Pacific market share: ~41% (largest market, led by China and India)

- Key end-users: Petrochemical (31%), metallurgy (17%), large-scale HVAC (19%), food processing (18%)

- Materials trend: >30% utilization rate for composite and advanced anti-corrosive alloys (2024 stat)

- Energy Impact: Facilities replacing old systems with modern Evaporative Condenser see CO2 emissions cut by 12–19% (independent study, see reference at bottom).

2. Core Technical Parameters & Product Comparison

| Parameter | Typical Value | Industrial Range | Notes |

|---|---|---|---|

| Cooling Capacity (kW) | 350–1800 | 100–5000+ | Depends on unit size/application |

| Design Pressure (MPa) | 1.6 | 1.0–2.5 | Meets ISO/ANSI/GB/T standards |

| Working Temperature (°C) | -10 ~ +60 | -15 to +80 | Custom solutions for extremes |

| Heat Exchange Coil Material | SS304/316L, HDG Steel, FRP | SS, copper, alloy | Anti-corrosive, high durability |

| Water Flow Rate (m³/h) | 36–250 | 10–800+ | Optimized for process needs |

| Fan Power (kW) | 2.2–18.5 | Up to 45 | IEC-certified motors |

| Noise Level (dB(A)) | 65–78 | 62–82 | Low-noise designs available |

| Coil Lifetime (years) | ≥18 | 12–22 | Tested under ISO 9001 |

Power Consumption Comparison (Evaporative vs. Air-Cooled vs. Water-Cooled)

Material Market Share in Evaporative Condenser Manufacturing (2024)

Average Service Lifespan by Material Type

3. Evaporative Condenser Manufacturing Process (With Flow Diagram)

Key Manufacturing Technologies

- Material: Industrial-grade SS304/SS316L, hot-dip galvanized steel, FRP composite, and oxygen-free copper. All comply with ISO 9001, ANSI/ASHRAE, and CE certifications.

- Core Processing: CNC tube bending (precision ±0.2mm), automatic TIG welding, robotic coil winding, injection molding for casing, precision leak and pressure testing (up to 2.5 MPa).

- Anti-corrosive Treatment: Multi-layer polyurethane, FEP/ETFE coating, or vinyl-ester resin for FRP (salt spray test ≥ 1200h).

- Quality Tests: Each unit tested for 150% design pressure (hydrostatic), air-tightness, and vibration per ISO/EN standards.

4. Application Scenarios: Evaporative Condenser Across Industries

Industry Coverage & User Value

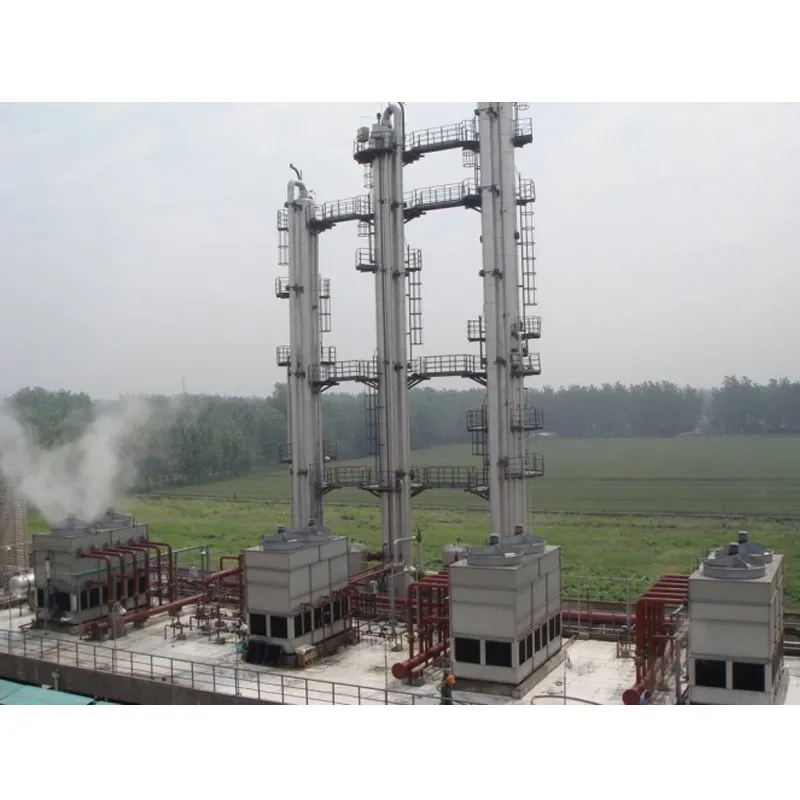

- Petrochemical Plants: Closed-loop cooling for hydrocarbon compressors, process distillation, and heat recovery units.

- Metallurgy & Steel: Blast furnace gas condensing, continuous casting cooling, high pressure/temperature operations.

- District Cooling & HVAC: Large-scale buildings, hospitals, data centers, malls (slashing annual cooling electric costs up to 15%).

- Industrial Refrigeration: Ammonia or Freon condensing for cold storage, food/petro distribution hubs.

- Water Treatment: Pre-treatment units for desalination/brine plants.

Customer Case Studies & Feedback

- Challenge: The original air-cooled system failed to meet energy targets and showed severe coil corrosion.

- Solution: Replaced with Evaporative Condenser system using SS316L with FRP casing.

- Outcome: Cooling efficiency +23%. Coil lifespan extended from 8 to 18 years. Facility CO2 output down 340t/year.

- User Feedback: "Operating cost cut by $27,500 annually. No unplanned downtime since commissioning. Highly recommend for heavy chemical sites."

5. Supplier Comparison — Mainstream Evaporative Condenser Brands

| Brand | Structure Material | Certifications | Typical Lead Time | Warranty | Markets |

|---|---|---|---|---|---|

| LONGXUAN | SS304/316L, HDG, FRP | ISO 9001, CE, ANSI | 20–30 days | 18 years coil | Global |

| Baltimore Aircoil | SS304, Galvanized steel | UL, ISO, ASHRAE | 45–65 days | 10–15 years | NA, EU, APAC |

| Evapco | SS304, HDG, Alloys | ISO, CE, Eurovent | 40–50 days | 15 years | Worldwide |

| Güntner | Aluminum, SS316L | ISO, DIN, UL | 35–54 days | 12–16 years | EU, Asia |

6. Custom Solutions and Engineering Services

- One-on-one engineering design based on project process, site layout, and climate (on-site CFD simulation support)

- Material optimization for anti-corrosion (FRP, custom alloys, hybrid casing)

- Fully custom Evaporative Condenser for non-standard refrigerants (ammonia, CO2, R134a, propylene)

- Quick-mount modules, remote PLC/BAS integration, IoT monitoring-enabled

- Full ISO and CE documentation, 3rd party pressure/leak testing accepted

7. Typical Application Cases

- Large copper refinery (2023): Reduced system water loss by 28%, all units met ISO 14001 environmental targets, ROI reached in 2.1 years.

- Data center (Shanghai, 2022): Low-noise Evaporative Condenser cut cooling energy by 16%. Zero major maintenance in 2 years.

- Drinking water bottling plant: Food grade SS316L material, 3rd party FDA-compliant coating, microbiological risk

8. Delivery Timelines, Quality Guarantees & Customer Support

- 🔧 Typical delivery (custom models): 20~40 working days. In-stock for standard types.

- 🛡️ Warranty: 18 years on coils, 2 years full unit. Site startup by certified technicians.

- 📑 International support: Documentation in English, French, Russian. Legendary 7/24 technical hotline.

- ✓ ISO 9001/14001 certified — 100% test-inspected, with calibration log and shipment records saved 5+ years.

9. Frequently Asked Questions (FAQ)

Prev This is the first article

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China