We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

As industrial cooling requirements push the boundaries for efficiency, reliability, and adaptation, the square cooling tower—particularly the FRP square cooling tower and advanced m square cooling tower systems—are emerging as market-leading solutions. Square type cooling towers present unique technological, structural, and operational advantages, making them the backbone of modern thermal management across chemical, metallurgy, HVAC, and energy sectors.

Industry Trends & Market Size for Square Cooling Tower

According to MarketsandMarkets, the global cooling tower market reached $2.9 billion in 2023, with the square type cooling tower segment accounting for over 36% of new industrial installations. The rise in adoption is attributed to the flexibility and higher thermal efficiency enabled by square designs, especially in FRP (fiberglass reinforced plastic) variants, offering anti-corrosive, lightweight, and low-maintenance properties.

What is a Square Cooling Tower?

Square cooling tower refers to a tower with a rectangular or square plan, optimized for counter-current or cross-flow operations. The design offers:

- Modular construction for scalability

- Higher packing density (infill volume/footprint ratio)

- Efficient air-water distribution for even heat rejection

- Adaptability to FRP or metal frameworks catering to various industries

- Better maintenance access and layout flexibility

Square Counter Current Cooling Tower: Technical Insights, Manufacturing & Design Flow

Product Overview

Product Name: Square Counter Current Cooling Tower

URL: https://www.longxuanfrp.com/square-cooling-tower-co-ltd.html

Raw Material Inspection → CNC Cutting & FRP Sheet Lamination

↓

Frame Fabrication & Infill Molding → Mechanical Assembly (Fan, Motor, Gearbox)

↓

Paint Curing (Anti-UV, Epoxy)

↓

Functional Testing (Airflow, Drift loss, Vibration)

↓

Compliance Inspection (ISO 9001, ANSI/CTI 201)

↓

Packaging & Shipment

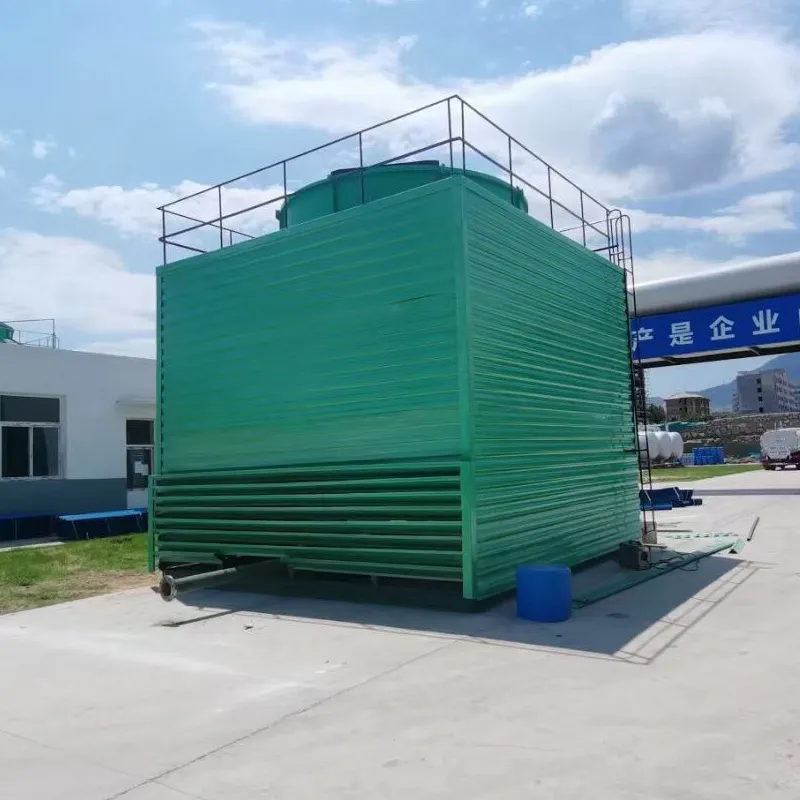

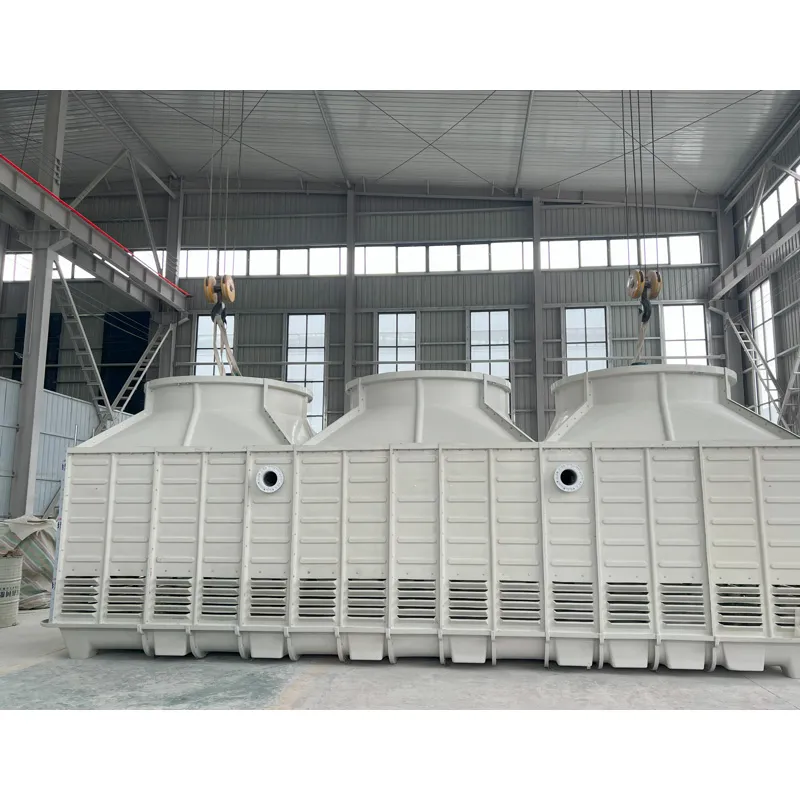

Featured Images: FRP Square Cooling Tower Assembly & Quality Control

Key Technical Parameters: Square Counter Current Cooling Tower

| Model | Capacity (m3/h) | Fan Power (kW) | Size (mm) | Noise (dB) | Material | Heat Rejection (kcal/h) |

|---|---|---|---|---|---|---|

| SCT-200 | 200 | 4.0 | 2150×2150×1650 | 63 | FRP/HDG Steel | 465,000 |

| SCT-400 | 400 | 7.5 | 3250×2150×1650 | 66 | FRP | 980,000 |

| SCT-800 | 800 | 15 | 4300×3250×2100 | 68 | FRP + Copper | 1,980,000 |

| SCT-1500 | 1500 | 22 | 6300×3250×2100 | 72 | FRP + SS304 | 3,650,000 |

Product Material & Manufacturing Excellence

- Materials: Premium FRP sheets (ISO-certified), HDG steel, anti-UV epoxy paint, corrosion-resistant infill media.

- Processes: Combination of CNC precision cutting, robotic lamination, stainless steel fastener use, and multi-point QC (step by step).

- Key Standards: ISO 9001, ANSI/CTI-201, GB/T 7190 (China).

- Service Life: 15-25 years (validated in chemical and steel plants, with >8,000h annual operation tested).

Square Cooling Tower Technology — How It Works

- Counter Current Flow Design: Hot water descends as air rises, maximizing temperature differential and heat rejection

- FRP Structure: Excellent anti-corrosive properties, UV/chemical resistance ideal for saline, acidic, or humid environments

- Low Drift Loss: Advanced drift eliminators reduce water loss <0.03% of circulation

- Energy-efficient Fan: Direct drive, inverter-compatible options reduce power use by up to 25%

- No Water Leakage: Modular panel assembly with precise gaskets ensures leakproof operation

Complete Specifications: Square Cooling Tower Family (Industry Table)

| Product | FRP Square Cooling Tower | M Square Cooling Tower | Square Type Cooling Tower |

|---|---|---|---|

| Capacity Range | 20~3000 m3/h | 50~2500 m3/h | 30~2000 m3/h |

| Infill Material | FRP + PVC | HDG Frame + FRP Panels | All FRP / Composite |

| Heat Rejection (Max) | 9,000,000 kcal/h | 6,800,000 kcal/h | 6,000,000 kcal/h |

| Noise | <67 dB(A) | <63 dB(A) | <70 dB(A) |

| Certifications | ISO 9001, CTI | ISO 9001/14001 | GB/T 7190.1-2015 |

| Water Drift Loss | <0.05% | <0.03% | <0.05% |

| Typical Service Life | 18-25 yrs | 15-22 yrs | 14-19 yrs |

| Application Field | Chemical, Power, HVAC | Steel, Textile, Data Center | Metallurgy, Electronics |

Application Areas & Use Case Scenarios

Petrochemical/Pipeline Cooling

Square counter current towers can handle high-temperature brine and corrosive chemicals. Case: Sinopec refinery realized a 21% energy reduction and 2.2x tower lifespan increase after upgrading to FRP square cooling tower.

Steel and Metallurgy Plants

M square cooling tower models are used to cool rolling mill discharge, achieving optimized water consumption, reduced scale formation, and high reliability—even above 70°C operation.

HVAC & Data Centers

Large commercial facilities deploy square type cooling tower banks for redundancy and modular expansion. Typical installation delivers up to 27% operating cost savings vs. cylindrical towers.

Textile/Dyeing Industry

High fiber dust and colored effluent conditions make fully composite square towers preferable for anti-fouling and ease of cleaning (customer: Vietnam SouthTextile).

Municipal Water/Food Processing

Corrosion-resistant options and low water drift loss benefit continuous food/agriculture plants—improving hygiene and system uptime (Nestle project, 2022).

Case Study: Square Cooling Tower in Steel Plant (2023)

Vendor Comparison: Why Choose Square Cooling Tower Co Ltd?

- R&D Strength: 20+ years, ISO/SGS certified, global Fortune 500 supplier

- Advanced Equipment: Full CNC line, automatic FRP lamination, imported test benches

- Turnkey Engineering: From custom 3D CAD/CFD design to commissioning, maintenance & AMP

- Export Network: 45+ countries, with large references in oil/gas, power, and high-tech plants

- Quality Culture: Lean production, strict component tracking, 72h continuous load test standard

- Size/Capacity: From compact 20m³/h up to mega 3500m³/h towers

- Material Option: FRP, SS304/316, copper tube, high corrosion-resistant infill and drift eliminator

- Environmental Fit: Extreme temperature (-35°C to +60°C), saline air, desert dust, acid fumes

- Integration: BMS-ready, digital monitoring, custom pipe/flange/foundation interfaces

- Accessory Lines: Mist eliminators, silencer covers, high-efficiency fan module, vibration sensors

Customer Experience & Feedback

"Upgrading to square cooling tower co ltd from a leading local manufacturer cut our maintenance by half and gave clear water cost reduction (from 0.19% to just 0.044% drift). The product is robust, easy to service, and our plant efficiency is up!"

— Facility Manager, Liansu Chemical, 2024

Delivery Time, Warranty & Customer Support

Warranty: 18 months from shipment / 12 months after commissioning

Support: 24x7 engineer response, on-site commissioning worldwide, dedicated after-sales portal

Spare Parts: Full kit and consumable replacements guaranteed for 15+ years

Professional FAQ & Terminology - Square Cooling Tower Series

Prev This is the first article

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China