We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Understanding Seawater Cooling Towers in Industrial Applications

In industrial processes, efficient heat rejection is paramount for optimal operation and sustainability. For facilities located near coastal areas or with access to abundant saline water sources, a specialized cooling solution is often employed: the seawater cooling tower. Unlike traditional freshwater cooling towers, these units are specifically engineered to withstand the highly corrosive nature of saltwater, ensuring long-term reliability and performance. They play a critical role in managing thermal loads in various demanding sectors, offering a robust and environmentally conscious alternative to once-through cooling systems. This advanced engineering addresses the unique challenges posed by saline environments, extending equipment lifespan and reducing operational complexities.

Our Circular Cooling Tower product line exemplifies this commitment to durability and efficiency in harsh conditions. These towers are designed to leverage the vast cooling potential of seawater while minimizing maintenance and maximizing energy savings. They are a prime example of a true water cooling tower system, utilizing evaporative principles to achieve significant temperature reductions without consuming precious freshwater resources. The robust construction and advanced material selection are key differentiators, ensuring consistent performance even under the most aggressive environmental stresses, which is critical for continuous industrial operations.

The Intricate Manufacturing Process of a Seawater Cooling Tower

The fabrication of a robust seawater cooling tower is a meticulous process demanding specialized materials and precision engineering. The primary challenge lies in combating the severe corrosive effects of saline water. Therefore, material selection is critical. Components that come into direct contact with seawater, such as the casing, basin, and fill media, are typically constructed from high-grade Fiber Reinforced Polymer (FRP) or corrosion-resistant alloys like marine-grade stainless steel (e.g., Duplex or Super Duplex Stainless Steel). FRP, particularly, offers an excellent strength-to-weight ratio and superior resistance to chemical attack and biological fouling inherent in seawater environments.

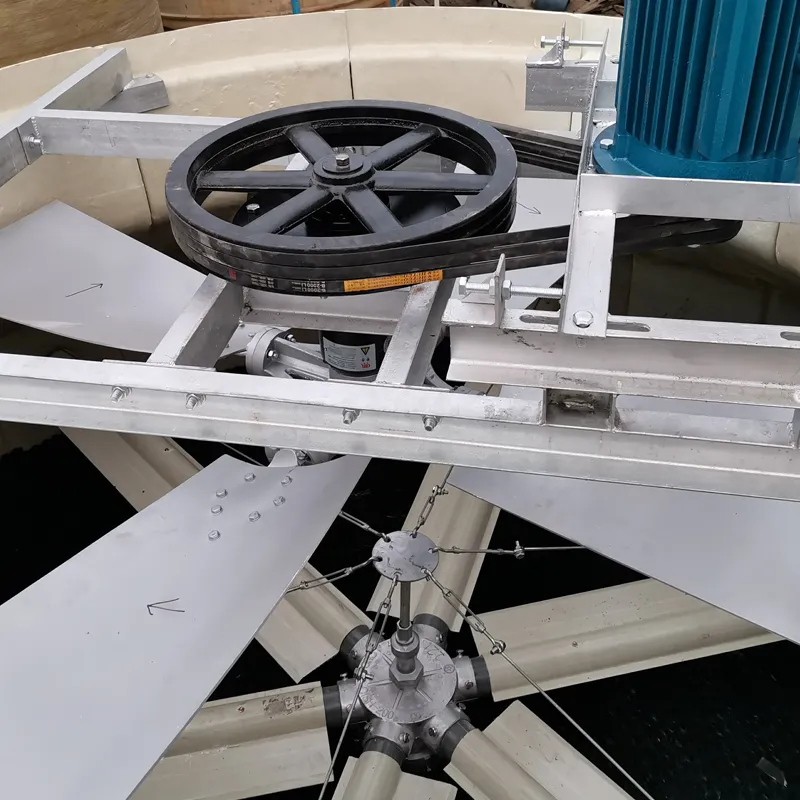

The manufacturing process begins with the precision molding of FRP components, often utilizing advanced filament winding or hand lay-up techniques to achieve consistent wall thickness and structural integrity. Critical metallic components, such as fan shafts, motor supports, and hardware, undergo rigorous casting or forging processes to achieve the required mechanical properties, followed by precision CNC machining for exact fitment. Every weld and joint is inspected to ensure hermetic seals and structural soundness. This intricate combination of material science and manufacturing expertise ensures the longevity and reliable performance of each seawater cooling tower, providing a design life often exceeding 20-30 years when properly maintained.

Image: Overview of the Seawater Cooling Tower manufacturing process.

Quality control is integrated at every stage, adhering to international standards such as ISO 9001 for quality management and ANSI/CTI standards for cooling tower performance. Non-destructive testing methods, including ultrasonic and dye penetrant inspections, are employed on critical welds and structural components to detect any potential flaws. Hydrostatic testing of the basin ensures watertight integrity, while dynamic balancing of fan assemblies guarantees vibration-free operation. These stringent detection standards ensure that each seawater cooling tower not only meets but often exceeds industry benchmarks for safety, durability, and efficiency, offering unparalleled reliability in demanding industrial settings.

Key Technical Parameters and Specifications

Selecting the right seawater cooling tower requires a thorough understanding of its technical specifications. Key parameters include heat rejection capacity (measured in Tons of Refrigeration, TR, or MW), water flow rate (GPM or m³/h), inlet and outlet water temperatures, wet bulb temperature, and approach temperature. These factors directly influence the tower's performance and energy consumption. For instance, a lower approach temperature indicates higher efficiency, meaning the tower can cool water closer to the ambient wet-bulb temperature. Drift loss, typically less than 0.005% of the circulating water flow, is another crucial parameter, especially in coastal areas to prevent salt deposition on surrounding equipment.

Image: Detailed view of Seawater Cooling Tower components.

Below is a generalized table outlining typical parameters for a high-performance Circular Cooling Tower designed for seawater applications. These values can vary based on specific project requirements and environmental conditions, emphasizing the need for custom engineering.

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Heat Rejection Capacity | Total heat dissipated from circulating water | 100 TR to 5000+ TR (350 kW to 17500+ kW) |

| Circulating Water Flow Rate | Volume of water processed per unit time | 150 GPM to 25,000+ GPM (35 m³/h to 5,600+ m³/h) |

| Inlet Water Temperature | Hot water temperature entering the tower | 35°C - 50°C (95°F - 122°F) |

| Outlet Water Temperature | Cooled water temperature leaving the tower | 28°C - 35°C (82.4°F - 95°F) |

| Wet Bulb Temperature | Ambient air wet bulb temperature | 25°C - 30°C (77°F - 86°F) |

| Drift Loss | Water lost as fine droplets in exhaust air | < 0.005% of circulating flow (with drift eliminators) |

| Noise Level (1m) | Sound pressure level at 1 meter distance | 65 - 85 dBA (depending on model/fan type) |

| Materials of Construction | Corrosion-resistant materials used in tower components | FRP (Casing, Basin, Fan Stack, Fill), SS316L/Duplex SS (Hardware, Fan Hub) |

| Design Life | Expected operational lifespan with proper maintenance | 20 - 30+ Years |

Image: Performance curve of a Seawater Cooling Tower.

Diverse Application Scenarios and Key Advantages

The application of a seawater cooling tower extends across various heavy industrial sectors, particularly those with high heat loads and coastal locations. These include, but are not limited to, petrochemical plants, where precise temperature control is vital for refining processes; metallurgical industries, which generate immense heat during metal production; and large-scale thermal power plant cooling tower systems, where they are integral to condenser cooling. Furthermore, they are crucial in desalination plants, industrial HVAC systems for large complexes, and offshore platforms. The ability of these towers to utilize an abundant, readily available resource like seawater makes them an economically viable and environmentally responsible choice for large-scale cooling requirements.

Image: Seawater Cooling Tower in a petrochemical complex.

The primary advantage of a seawater cooling tower lies in its exceptional corrosion resistance, achieved through meticulous material selection and protective coatings. This significantly extends the equipment's lifespan and reduces maintenance costs associated with saltwater degradation. Beyond durability, these towers offer substantial energy savings. By utilizing evaporative cooling, they achieve lower process temperatures than air-cooled systems, leading to higher efficiency in connected machinery and processes. This translates into reduced energy consumption for the entire plant. Compared to a traditional spray pond and cooling tower configuration, the contained design of modern cooling towers offers better control over drift, minimizing environmental impact and salt spray.

Image: Optimized airflow for energy efficiency in a Seawater Cooling Tower.

Furthermore, the reliance on an abundant saltwater source eliminates the need for large volumes of freshwater, a critical consideration in regions facing water scarcity. This makes the seawater cooling tower an environmentally sustainable choice. Its compact footprint, especially for Circular Cooling Tower designs, allows for efficient land use, which is a significant advantage in densely populated industrial zones. The integrated design and robust construction ensure minimal downtime and reliable operation, critical for continuous production processes in industries like steel manufacturing and power generation. The strategic implementation of a true water cooling tower system can significantly enhance operational resilience and reduce overall environmental footprint.

Choosing Your Seawater Cooling Tower: Key Considerations

When selecting a seawater cooling tower manufacturer, several factors come into play beyond just price. Expertise in corrosion-resistant materials and engineering for saline environments is paramount. Look for manufacturers with a proven track record, demonstrated through service history, client testimonials, and adherence to international quality and performance standards like ISO 9001 and CTI (Cooling Technology Institute) certifications. Companies like Longxuan FRP, with years of specialized experience in FRP composites for industrial applications, exemplify this authoritative approach. Their commitment to research and development ensures that their Circular Cooling Tower products incorporate the latest advancements in materials science and thermal design.

Image: Custom-designed Seawater Cooling Tower for specific site requirements.

Customization options are also crucial, as no two industrial sites are identical. A reputable manufacturer should offer bespoke solutions tailored to specific heat rejection capacities, footprint constraints, and operational parameters. This includes varying fan types (axial or centrifugal), fill media design (film or splash), and structural configurations to optimize performance and minimize total cost of ownership. For instance, a thermal power plant cooling tower might require higher capacities and specific materials to handle elevated temperatures and continuous operation, necessitating a highly customized approach to its design and fabrication.

Real-World Application and Trustworthiness: Case Studies & Support

Our Circular Cooling Tower, designed as a robust water cooled cooling tower for marine environments, has been successfully deployed in diverse industrial settings. For instance, a large-scale chemical processing plant on the Arabian Gulf coast required a high-capacity cooling solution that could withstand extreme temperatures and highly saline input water. Our customized Circular Cooling Tower, featuring a Duplex stainless steel structure and high-performance FRP casing, delivered consistent cooling for their primary reactors, leading to a reported 15% reduction in cooling energy consumption compared to their previous system and a significant extension in maintenance intervals due to superior corrosion resistance. This tangible success story underscores the product's ability to perform reliably in challenging operational contexts.

Image: Successful installation of a Seawater Cooling Tower in an industrial project.

Another example includes a major steel mill upgrade project, where an aging `spray pond and cooling tower` system was replaced by multiple compact Circular Cooling Tower units. This not only optimized space utilization but also drastically improved cooling efficiency and reduced water loss through drift, contributing to the mill’s environmental compliance goals. These real-world applications demonstrate the practical benefits and proven performance of our seawater cooling tower solutions. Our rigorous testing data, often validated by third-party certifications like FDA approval for materials used in certain processes or API standards for oil & gas applications, further reinforces our commitment to product quality and reliability.

Image: Dedicated customer support for Seawater Cooling Tower clients.

Frequently Asked Questions (FAQ)

Q1: What are the main differences between a seawater cooling tower and a freshwater cooling tower?

The primary difference lies in the materials of construction. Seawater cooling tower units are built with highly corrosion-resistant materials such as FRP composites, marine-grade stainless steel (e.g., Duplex SS), and specialized coatings to withstand the aggressive nature of saltwater. Freshwater towers typically use galvanized steel or less resistant plastics. Additionally, drift eliminators in seawater towers are designed to minimize salt carryover to a much stricter degree.

Q2: How does a true water cooling tower handle biological fouling in seawater?

Biological fouling (e.g., algae, barnacles) is a common challenge in seawater systems. Our Circular Cooling Tower addresses this through several mechanisms: smooth, non-porous FRP surfaces that are less prone to bio-growth, and designs that facilitate easy cleaning and maintenance. For severe cases, integrated or external water treatment systems (e.g., anti-fouling coatings, filtration, chemical dosing) can be incorporated into the overall cooling loop to mitigate bio-fouling and ensure optimal thermal performance.

Q3: What is the typical lead time and warranty for a Circular Cooling Tower?

The delivery schedule for a seawater cooling tower depends on its size, complexity, and customization requirements. Typically, fabrication and delivery range from 12 to 24 weeks. We provide a comprehensive warranty, usually 18-24 months from the date of shipment or 12-18 months from commissioning (whichever comes first), covering material and manufacturing defects. Our robust customer support includes technical assistance, spare parts availability, and on-site service to ensure your investment operates reliably throughout its long lifespan.

Image: Comprehensive support for your Seawater Cooling Tower.

References

- Cooling Technology Institute. (2020). CTI Standards and Guidelines for Thermal Performance and Materials.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality Management Systems.

- American Society of Mechanical Engineers. (2019). ASME Boiler and Pressure Vessel Code.

- US Environmental Protection Agency. (2014). Technical Development Document for the Final Section 316(b) Rule.

- Journal of Corrosion Science and Engineering. (2021). Advances in Materials for Seawater Applications.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China