We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Understanding Enamel Water Tanks: A B2B Perspective

In industrial and commercial applications, reliable and durable water storage solutions are paramount. The enamel water tank stands out as a superior choice, offering exceptional longevity and corrosion resistance compared to conventional alternatives. These tanks are meticulously engineered to meet stringent industry demands, ensuring high-purity water storage for diverse sectors ranging from municipal water treatment to heavy industrial processes. Their unique construction, involving a fusion of inert glass-like material to a steel substrate, provides an impermeable barrier against common corrosive agents, making them a cornerstone for sustainable infrastructure projects requiring large water tanks for sale.

This comprehensive overview delves into the technical intricacies, practical applications, and compelling advantages of these advanced storage systems. We will explore the rigorous manufacturing processes, key technical specifications, and real-world benefits that position vitreous enamel coated tanks at the forefront of modern water management.

The Advanced Manufacturing Process of Enamel Water Tanks

The production of an enamel water tank is a highly specialized process, ensuring the fusion of steel's structural integrity with glass's inertness. This multi-stage manufacturing sequence guarantees a product that excels in durability and performance. It typically begins with the precise fabrication of steel sheets, which are cut, rolled, and formed to exact specifications. These steel components undergo meticulous surface preparation, including grit blasting, to achieve a pristine surface free from impurities, which is crucial for optimal enamel adhesion.

Following surface preparation, multiple layers of vitreous enamel frit, a specially formulated glass mixture, are applied. Each layer is then fired at extremely high temperatures, typically between 800°C and 900°C, in a controlled furnace. This high-temperature firing process causes the enamel to melt and chemically bond with the steel, creating a homogeneous, highly durable, and impermeable surface. This fusion not only provides exceptional corrosion resistance but also offers superior abrasion resistance and hygienic properties, critical for potable water storage and chemical processing.

Quality control is integrated at every stage, with adherence to international standards such as ISO 9001 for quality management and ANSI/AWWA D103 for bolted steel tanks, ensuring product consistency and reliability. Post-firing, each panel undergoes thorough inspection for defects, thickness uniformity, and adhesion strength, often utilizing non-destructive testing methods. This rigorous process yields a tank with an expected service life exceeding 30 years, significantly longer than many alternative storage solutions, making them a cost-effective investment for industries like petrochemical, metallurgy, and water supply and drainage.

Fig 1: Schematic of Enamel Application Process for Tanks.

Key Technical Parameters and Specifications

Understanding the technical specifications is crucial for selecting the appropriate enamel water tank for specific project requirements. These tanks are designed to accommodate a wide range of volumes and operational conditions, offering flexibility for various industrial and municipal applications. Below is a table outlining typical parameters and specifications for a high-quality vitreous enamel coated tank, demonstrating the robust engineering behind these storage solutions.

| Parameter | Typical Specification | Description |

|---|---|---|

| Tank Volume Range | 20 m³ to 20,000 m³+ | Scalable solutions for various storage needs. |

| Panel Material | Titanium-rich steel (Q235/Q345) | High strength steel optimized for enamel adhesion. |

| Enamel Coating Thickness | 250 - 450 microns (per side) | Optimal thickness for durability and corrosion resistance. |

| pH Range Resistance | pH 1 to pH 14 | Resistant to highly acidic and alkaline solutions. |

| Operating Temperature | -40°C to 200°C | Withstands extreme temperature variations. |

| Design Life | 30+ years | Long-term reliability and minimal maintenance. |

| Compliance Standards | ISO 28765, ANSI/AWWA D103, OSHA | Meets international and regional safety/quality standards. |

Fig 2: Technical drawing of an Enamel Water Tank.

Technical Advantages and Application Versatility

The inherent properties of glass-fused-to-steel technology provide distinct advantages that make enamel water tanks a preferred choice for demanding environments. Foremost among these is unparalleled corrosion resistance. The inert glass lining prevents direct contact between the stored substance and the steel, effectively eliminating rust and degradation, even when storing highly corrosive liquids or operating in aggressive ambient conditions. This significantly extends the service life of the tank, minimizing replacement costs and operational downtime over decades.

Furthermore, the smooth, non-porous surface of the enamel offers exceptional hygiene. It inhibits bacterial growth and biofilm formation, making these tanks ideal for potable water storage, wastewater treatment, and food processing industries where product purity is paramount. This ease of cleaning and low maintenance requirement contribute to long-term cost savings. The modular design of large water tanks for sale of this type also allows for rapid installation and future expansion, reducing project timelines and complexity. Their robust construction ensures structural integrity even under seismic loads or extreme weather conditions, as demonstrated in numerous global installations.

Fig 3: Interior view highlighting the smooth enamel lining.

Diverse Application Scenarios:

- Potable Water Storage: Ensuring safe and clean drinking water for communities and industrial facilities.

- Wastewater Treatment: Critical for anaerobic digesters, equalization tanks, and sludge storage due to resistance to aggressive chemical environments.

- Fire Suppression Systems: Providing reliable water reserves for critical safety infrastructure.

- Industrial Process Water: From chemical processing to power generation, handling various types of industrial water.

- Bioenergy and Biogas: Ideal for storing agricultural digestate and other biogas components.

- Agriculture: Irrigation water storage, livestock watering, and manure management.

Fig 4: Enamel tank in a municipal water treatment plant.

Enamel Water Tank vs. Alternative Materials: A Comparative Analysis

When evaluating large water tanks for sale, it's essential to compare the performance and cost-effectiveness of different materials. While stainless steel, fiberglass reinforced plastic (FRP), and concrete tanks have their niches, the vitreous enamel coated tank often presents a superior long-term value proposition due to its unique material properties.

| Feature | Enamel Water Tank (GFS) | Stainless Steel Tank | FRP Tank | Concrete Tank |

|---|---|---|---|---|

| Corrosion Resistance | Excellent (pH 1-14) | Good (pH dependent, susceptible to pitting) | Good (resin dependent, can degrade with UV) | Fair (porous, requires liners/coatings) |

| Service Life | 30+ years | 20-30 years (with proper maintenance) | 15-25 years | 20-50 years (requires ongoing sealing) |

| Installation Speed | Fast (modular, bolted construction) | Moderate (welded, can be slow for large sizes) | Moderate to Fast (pre-fab sections) | Slow (on-site casting) |

| Maintenance Needs | Very Low | Moderate (cleaning, passivation) | Moderate (surface degradation, cracking) | High (sealing, crack repair) |

| Cost (Initial) | Moderate to High | High | Moderate | Low to Moderate |

| Cost (LCC - Life Cycle Cost) | Low | Moderate to High | Moderate | High |

This comparison highlights that while the initial investment for an enamel water tank might be comparable to, or slightly higher than, some alternatives, its significantly lower life cycle cost, driven by minimal maintenance and extended operational lifespan, offers superior long-term economic benefits. This makes it a strategically sound choice for large-scale industrial and municipal projects where reliability and cost-efficiency are critical.

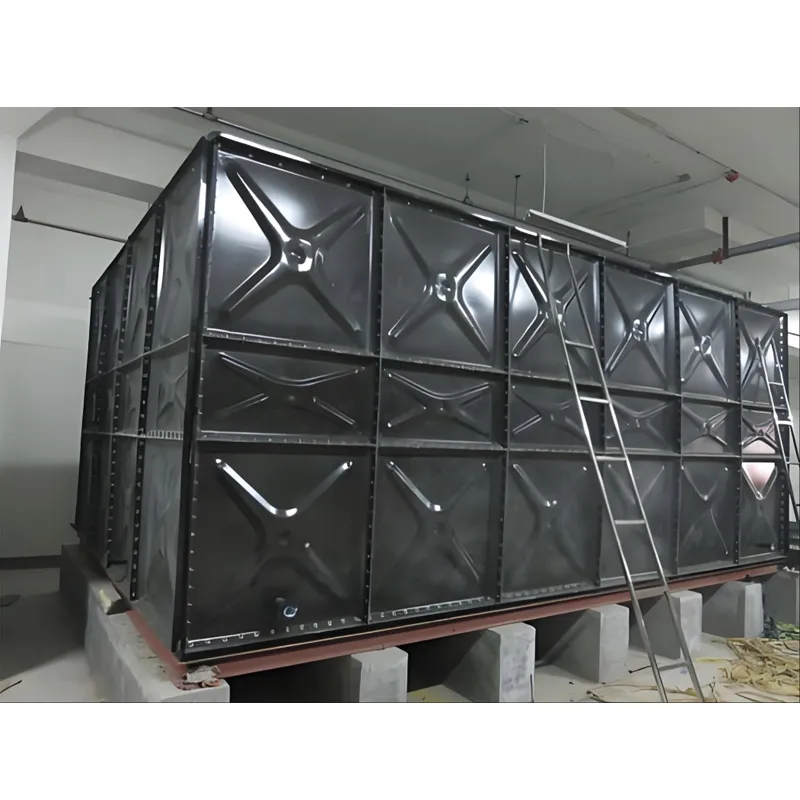

Fig 5: A fully assembled Enamel Water Tank.

Customization and Project Implementation Excellence

Recognizing that every B2B project presents unique challenges, leading manufacturers of enamel water tanks offer comprehensive customization services. This includes tailoring tank dimensions, capacities, and accessories (such as nozzles, ladders, platforms, and insulation) to precisely match specific site conditions and operational requirements. Whether it's for an unconventional footprint or a need for specialized inlet/outlet configurations, engineering teams work closely with clients from conceptual design through to commissioning.

Project implementation excellence is a hallmark of reputable suppliers. This encompasses not only delivering high-quality vitreous enamel coated tank panels but also providing detailed installation guides, technical support, and, if required, on-site supervision or complete turnkey installation services. This integrated approach minimizes potential risks, ensures smooth project execution, and guarantees optimal performance of the installed system. Decades of experience in delivering complex projects globally further underscore the commitment to client success and adherence to rigorous deadlines and budgets.

Fig 6: Custom design and manufacturing for specific project needs.

Ensuring Trust and Authority: Certifications and Support

For B2B buyers, trust and authority are built upon a foundation of proven quality, adherence to standards, and robust customer support. Reputable manufacturers of enamel water tanks proudly display certifications such as ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), and OHSAS 18001 (Occupational Health and Safety). Compliance with international product standards like ANSI/AWWA D103 for bolted steel tanks and NSF/ANSI 61 for potable water components further validates product safety and performance.

Beyond certifications, a strong commitment to client satisfaction is demonstrated through comprehensive after-sales support. This typically includes a transparent delivery cycle, clearly defined warranty periods (e.g., 5-year material warranty), and readily available technical assistance for the entire lifespan of the enamel water tank. Professional firms often provide a 24/7 client support line, spare parts availability, and routine maintenance recommendations to ensure continuous, trouble-free operation. This holistic approach significantly enhances the reliability and trustworthiness of the supplier.

Fig 7: Rigorous quality control and inspection processes.

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time for an enamel water tank?

A1: Lead times vary based on tank size, customization, and current production schedules. Typically, a standard vitreous enamel coated tank can be manufactured and ready for shipment within 4-8 weeks, with large or highly customized projects requiring 10-16 weeks. Specific timelines are provided during the quotation phase.

Q2: Can enamel water tanks be used for storing chemicals other than water?

A2: Yes, the enamel coating provides excellent resistance to a wide range of chemicals, including many acids and alkalis. It is crucial to provide the specific chemical composition and concentration to the manufacturer for compatibility assessment and to ensure the correct enamel formulation is used. Always consult product datasheets for chemical resistance before use.

Q3: What maintenance is required for an enamel water tank?

A3: One of the significant advantages of these tanks is their low maintenance requirement. Routine inspections for external damage and checking of sealant integrity are generally sufficient. The smooth enamel interior prevents scale build-up and corrosion, drastically reducing the need for internal cleaning or re-coating compared to other tank types.

Conclusion

The enamel water tank represents a pinnacle in water storage technology, offering a robust, long-lasting, and hygienic solution for critical industrial and municipal applications. Its superior corrosion resistance, extended design life, rapid installation capabilities, and minimal maintenance requirements translate into substantial long-term savings and enhanced operational efficiency. For enterprises seeking reliable large water tanks for sale, the investment in a vitreous enamel coated tank is a strategic decision that promises unparalleled performance and return on investment over decades.

References

- American Water Works Association (AWWA) Standard D103: Factory-Coated Bolted Carbon Steel Tanks for Water Storage.

- International Organization for Standardization (ISO) 28765: Vitreous and porcelain enamels - Design of bolted steel tanks for the storage of water or municipal or industrial effluents.

- National Sanitation Foundation (NSF) / American National Standards Institute (ANSI) Standard 61: Drinking Water System Components – Health Effects.

- European Committee for Standardization (CEN) EN 15282: Vitreous and porcelain enamels - Enamelled articles for equipment for the preparation of food.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China