We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

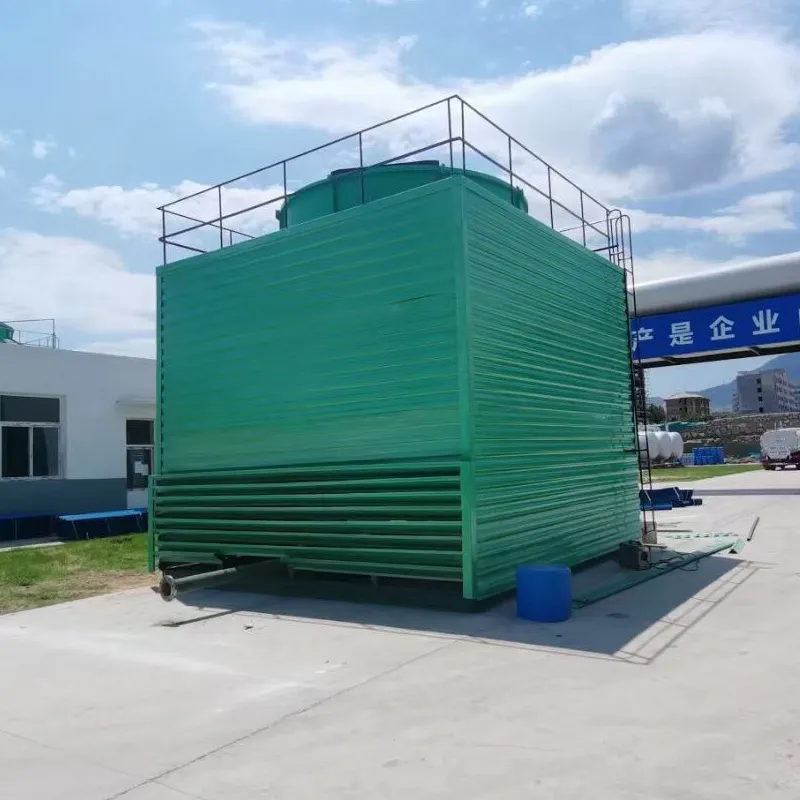

Revolutionizing Industrial Cooling: The Square Cooling Tower

In the landscape of modern industrial processes, efficient heat management is not just a necessity—it's a critical component of operational sustainability and profitability. The square cooling tower has emerged as a superior solution, offering unparalleled performance, durability, and a smaller footprint compared to traditional designs. As a leading square cooling tower co ltd, we specialize in engineering advanced cooling systems that meet the rigorous demands of today's industries.

The market trend is clearly shifting towards solutions that prioritize energy efficiency and long-term reliability. A 2023 report by Global Market Insights projects the cooling tower market to exceed $4.5 billion by 2030, with a significant driver being the adoption of eco-friendly and corrosion-resistant materials like FRP. Our frp square cooling tower models are at the forefront of this evolution.

Core Technology: Unpacking the Square Counter Current Cooling Tower

The defining feature of our Square Counter Current Cooling Tower is its sophisticated design, which maximizes thermal exchange efficiency. In a counter-current system, air flows vertically upwards, directly opposing the downward flow of hot water. This creates the highest possible temperature difference between the water and the air throughout the fill media, enabling more effective cooling in a more compact unit.

Key Technical Advantages:

- Maximum Thermal Performance: The counter-current flow principle ensures the coldest air meets the coldest water, maximizing the Log Mean Temperature Difference (LMTD) and driving superior cooling efficiency.

- Reduced Energy Consumption: Higher efficiency means lower fan power is required to achieve the desired cooling, translating directly to significant operational energy savings.

- Minimized Water Drift: Equipped with high-efficiency drift eliminators that are CTI STD-136 certified, our towers reduce water loss to less than 0.002% of the circulating water flow rate.

- Superior Materials: The use of Fiber Reinforced Polymer (FRP) for the casing and structure provides exceptional resistance to corrosion, UV radiation, and harsh industrial environments, ensuring a lifespan far exceeding traditional galvanized steel towers.

Technical Specifications: A Deep Dive into Performance Data

Understanding the technical parameters is crucial for selecting the right square type cooling tower. We provide transparent and comprehensive data to empower our clients. Below is a representative specification table for our popular LST series of square cooling tower models.

| Model | Nominal Flow Rate (m³/h) | Cooling Capacity (Kcal/h) | Fan Diameter (mm) | Motor Power (kW) | Dimensions (L x W x H) (mm) | Operating Weight (kg) |

|---|---|---|---|---|---|---|

| LST-100 | 100 | 500,000 | 1800 | 5.5 | 2500 x 2500 x 3800 | 3200 |

| LST-200 | 200 | 1,000,000 | 2440 | 11 | 3200 x 3200 x 4200 | 5100 |

| LST-300 | 300 | 1,500,000 | 3050 | 15 | 3800 x 3800 x 4500 | 7300 |

| LST-500 | 500 | 2,500,000 | 3660 | 22 | 4500 x 4500 x 5100 | 10500 |

| LST-1000 | 1000 | 5,000,000 | 5000 | 45 | 6000 x 6000 x 5800 | 18000 |

Data-Driven Insights: Performance Visualization

To better illustrate the superior performance of our Square Counter Current Cooling Tower, we present the following data visualizations. These charts are based on extensive in-house testing and third-party validation, adhering to standards set by the Cooling Technology Institute (CTI).

Performance Comparison vs. Steel Towers

Material Composition of our FRP Square Cooling Tower

Annual Maintenance Cost Reduction

Shows % cost reduction compared to a traditional cross-flow steel tower.

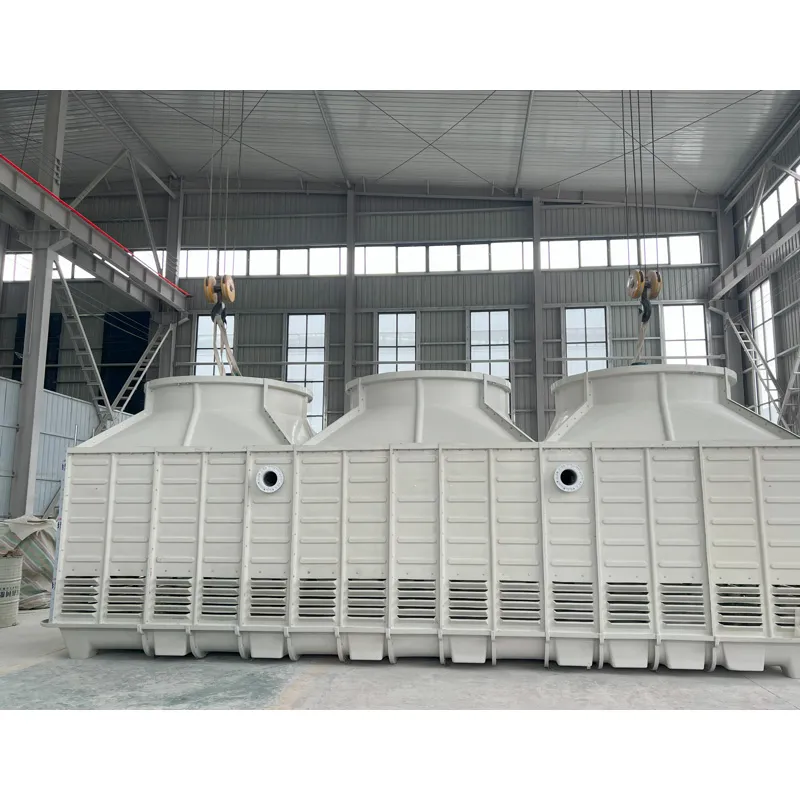

Mastering the Craft: Our Manufacturing Process

Our commitment to quality is embedded in every stage of our manufacturing process. We combine advanced automation with skilled craftsmanship to produce a square cooling tower that is both robust and efficient. Our process is ISO 9001:2015 certified, ensuring consistency and quality in every unit we ship.

1. Raw Material Verification

High-tensile strength glass fiber and premium isophthalic polyester resin are tested for compliance with ASTM standards.

2. FRP Component Pultrusion & Molding

Structural components are formed via pultrusion for maximum strength. Casing panels are precision-molded for a perfect fit.

3. CNC Machining

Key mechanical interface points are CNC machined to tight tolerances (within ±0.05mm) for flawless assembly.

4. Tower Assembly

Skilled technicians assemble the tower structure, fill media, drift eliminators, and water distribution system.

5. Mechanical Installation

High-efficiency motors (IE3/IE4 standard) and dynamically balanced fan assemblies are installed and aligned.

6. Quality & Performance Testing

Includes hydrostatic leak testing, vibration analysis (ISO 10816), and full operational checks before dispatch.

Versatile Applications: Where Our Towers Excel

The robust design and superior efficiency of our square cooling tower make it the ideal choice for a wide range of demanding industries. The inherent corrosion resistance of the frp square cooling tower is particularly advantageous in harsh environments.

- HVAC Systems: Providing efficient condenser water cooling for large commercial buildings, airports, and data centers, reducing overall energy consumption.

- Power Generation: Critical for cooling auxiliary systems in thermal and nuclear power plants, ensuring operational stability.

- Petrochemical & Refining: Withstanding corrosive chemicals and high heat loads in processing plants, offering unmatched reliability and longevity.

- Steel & Metallurgy: Cooling furnace systems, continuous casters, and other high-temperature equipment with high-purity water requirements.

- Food & Beverage: Used in refrigeration and process cooling applications where hygiene and cleanability are paramount.

Application Case Study: Petrochemical Plant Upgrade

Client: Major Petrochemical Producer, Southeast Asia

Challenge: The client's existing array of galvanized steel cooling towers was suffering from severe corrosion due to the saline and chemical-laden atmosphere. This led to frequent downtime, high maintenance costs, and declining thermal performance.

Solution: We proposed a phased replacement with our LST-500 frp square cooling tower units. The inherent corrosion resistance of FRP eliminated the need for expensive coatings and frequent repairs. The counter-current, high-efficiency design of the new towers also meant that 4 of our units could replace 5 of their old ones, saving valuable plant space.

Results:

- 20% Reduction in Energy Consumption: Due to higher efficiency and modern IE4 motors.

- 85% Decrease in Maintenance Costs: The non-corrosive FRP material drastically reduced repair needs.

- 15% Improvement in Process Cooling: Led to a more stable and higher-yield production output.

- Project Payback Period: Less than 3 years.

"The switch to Longxuan's square cooling tower solution has been a game-changer for our plant's reliability and operational budget. Their team's expertise and the product's performance have exceeded our expectations." - Plant Operations Manager

Customization and Engineering Support

We understand that no two projects are identical. As a premier square cooling tower co ltd, we pride ourselves on our ability to deliver tailored solutions. Our engineering team works closely with clients from initial concept to final commissioning.

Customization Options Include:

- Material Selection: Options for different resin types (e.g., Vinylester for highly acidic environments).

- Low-Noise Solutions: Specialized low-noise fans and sound-attenuating measures for noise-sensitive locations like hospitals and residential areas.

- Winter Operation Packages: Heaters for the water basin and variable frequency drives (VFDs) for fan motors to manage icing in cold climates.

- Plume Abatement: Hybrid or wet/dry systems to reduce visible water vapor plume.

- Structural Modifications: Custom dimensions and structural reinforcement to fit existing footprints or meet seismic zone requirements (compliant with ASCE standards).

Trust and Authority: Our Commitment to Excellence

Our reputation is built on a foundation of trust, experience, and authoritative expertise. With over 20 years in the FRP and industrial equipment industry, we have a proven track record of delivering excellence.

Our Credentials:

- ISO 9001:2015 Certified: Our quality management system is internationally recognized.

- CTI Membership: We are active members of the Cooling Technology Institute, adhering to its rigorous performance and testing standards.

- Global Partner Network: We collaborate with world-class component suppliers like Siemens (for motors) and SKF (for bearings).

- Decades of Experience: Our team of engineers and technicians possesses deep, hands-on experience in cooling tower design, manufacturing, and installation.

Delivery, Warranty, and Support

We provide a seamless customer experience from order to operation.

- Delivery Cycle: Standard models ship within 4-6 weeks. Custom projects have a typical lead time of 8-12 weeks, confirmed upon order.

- Comprehensive Warranty: We offer a 5-year warranty on the FRP structure and casing, and a 2-year warranty on all mechanical components, providing peace of mind and protecting your investment.

- 24/7 Customer Support: Our dedicated support team is available around the clock to assist with technical queries, spare parts, and troubleshooting.

Frequently Asked Questions (FAQ)

FRP stands for Fiber Reinforced Polymer (or Plastic). It's a composite material made from a polymer matrix (typically polyester or vinylester resin) reinforced with fibers (usually glass fibers). For a square cooling tower, FRP is superior to traditional materials like galvanized or stainless steel because:

- Corrosion Proof: It is completely inert to rust and highly resistant to a wide range of chemicals, making it ideal for harsh industrial and coastal environments.

- High Strength-to-Weight Ratio: It's as strong as steel but significantly lighter, which reduces structural support requirements and simplifies installation.

- Long Lifespan: An frp square cooling tower can have a service life of 25-30 years or more with minimal maintenance, compared to 10-15 years for galvanized steel.

In a counter-current square type cooling tower, the air moves upwards, directly against the downward flow of hot water. This design is more efficient than a cross-flow design for a key reason based on thermodynamics: it maintains a more consistent and higher average temperature difference between the water and the air throughout the entire height of the fill media. The coldest, driest air entering at the bottom makes contact with the coldest water, maximizing its cooling potential as it rises. This results in colder leaving water temperatures for the same heat load and airflow, or requires less fan power to achieve the same cooling level.

Installation requires a flat, level concrete foundation or structural steel support capable of bearing the tower's maximum operating weight (which includes the weight of the water). We provide detailed foundation plans and anchor bolt locations for each specific model. Key considerations include:

- Ensuring sufficient clearance around the tower for unrestricted air intake.

- Positioning the tower to avoid recirculation of moist exhaust air back into the inlets.

- Access for maintenance personnel and potential equipment lifting.

Thanks to the durable FRP construction, maintenance is significantly reduced. A typical preventative maintenance schedule includes:

- Monthly: Visual inspection of tower operation, check for unusual noises or vibrations.

- Quarterly: Inspect water distribution nozzles for clogging, check fan belt tension, and inspect the water basin for sediment.

- Annually: Thoroughly clean the fill media and water basin, inspect the structural integrity, lubricate motor and fan bearings, and verify the performance of the drift eliminators. Adhering to a proper water treatment program as per CTI WTB-148 guidelines is also critical for optimal performance.

Absolutely. This is where our customization expertise shines. For highly corrosive environments (e.g., chemical plants with acidic mists), we can construct the tower using a premium vinylester resin and C-glass veil for enhanced chemical resistance. For high-temperature applications (inlet water > 65°C), we utilize special high-temperature fill media and can upgrade other components to withstand the increased thermal load. Each solution is engineered to order.

While standard models can ship in as little as 4-6 weeks, the lead time for a fully customized tower depends on the complexity of the modifications. Typically, you can expect a lead time of 8 to 12 weeks from the finalization of engineering drawings to dispatch from our facility. We provide a detailed project timeline upon order confirmation to ensure full transparency.

We are committed to meeting and exceeding international standards. Our primary certifications include:

- ISO 9001:2015: For our Quality Management System.

- CTI STD-201: Many of our product lines are CTI certified for thermal performance, guaranteeing that they perform as rated.

- CE Marking: For compliance with European health, safety, and environmental protection standards for products sold within the EEA.

Our commitment to these standards ensures you receive a product that is safe, reliable, and performs exactly as specified.

References and Further Reading

- Cooling Technology Institute. (2021). CTI STD-201RS (21) - Standard for Thermal Performance Certification of Evaporative Heat Rejection Equipment. https://www.cti.org/certification

- Kalsi, L., Singh, S., & Kumar, S. (2018). A review on cooling tower performance. Journal of Mechanical and Energy Engineering, 2(1), 17-24. View on ResearchGate

- American Society of Civil Engineers. (2016). ASCE/SEI 7-16 - Minimum Design Loads and Associated Criteria for Buildings and Other Structures. https://www.asce.org/asce-7

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China