We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

The Core of Industrial Refrigeration: Advanced Evaporative Condenser Solutions

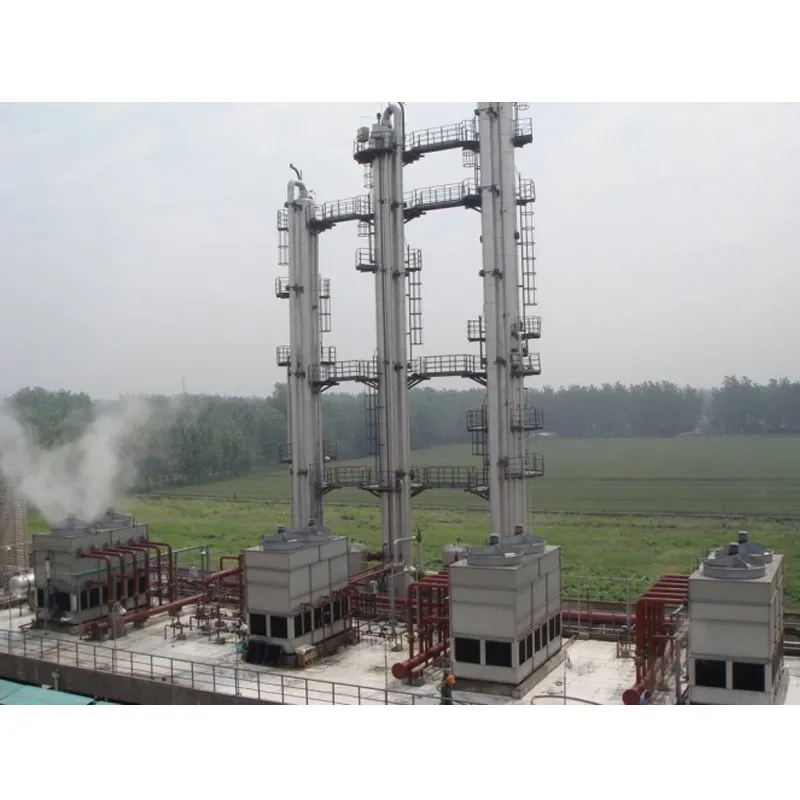

In the intricate world of industrial refrigeration and process cooling, efficiency, reliability, and sustainability are not just buzzwords but critical operational imperatives. Among the various heat rejection technologies available, the Evaporative Condenser stands out as a highly effective and energy-efficient solution for condensing refrigerant vapor in large-scale cooling systems. Unlike traditional air-cooled or water-cooled condensers, evaporative condensers leverage the principle of evaporative cooling to achieve lower condensing temperatures, translating directly into reduced compressor work and significant energy savings. This technology is particularly vital in applications where consistent, low condensing pressures are paramount for optimal system performance, such as in large cold storage facilities, chemical processing plants, food and beverage production, and HVAC systems for expansive commercial complexes. The fundamental advantage lies in their ability to reject heat to the ambient wet-bulb temperature, which is inherently lower than the dry-bulb temperature, offering a substantial thermodynamic benefit. This makes them an indispensable component in Ammonia (NH3) refrigeration systems, Freon systems, and various industrial cooling processes requiring efficient heat dissipation. Understanding the intricate design, robust manufacturing, and diverse applications of these critical components is essential for industry stakeholders seeking to optimize their operational expenditure, minimize environmental impact, and ensure the long-term reliability of their cooling infrastructure. Our commitment is to provide a comprehensive overview, delving into the technical intricacies, market dynamics, and unparalleled advantages that modern evaporative condensers bring to the industrial landscape, supported by decades of engineering expertise and a steadfast dedication to quality. The integration of advanced materials, precision manufacturing techniques, and rigorous testing protocols ensures that each unit delivers exceptional performance and an extended service life even in the most demanding environments. This article aims to equip B2B decision-makers and technical personnel with the insights necessary to make informed choices regarding their cooling system investments, focusing on real-world data, verifiable performance metrics, and a deep understanding of the product lifecycle. The growing emphasis on environmental stewardship and energy conservation has further accelerated the adoption of evaporative condensers, cementing their role as a cornerstone technology for sustainable industrial operations globally.

Industry Trends and Technological Evolution in Evaporative Condensers

The industrial refrigeration sector is currently undergoing a significant transformation, driven by a confluence of factors including stringent environmental regulations, escalating energy costs, and the relentless pursuit of operational efficiency. Within this evolving landscape, the evolution of the Evaporative Condenser technology has been particularly noteworthy. A primary trend is the push towards higher energy efficiency ratios (EER) and coefficients of performance (COP), necessitating design innovations that minimize fan power, pump power, and compressor energy consumption. This includes the development of more aerodynamically efficient fan blades, optimized spray nozzle designs for superior water distribution, and advanced heat exchange coil configurations that maximize heat transfer area and efficiency. Another critical trend is the increasing adoption of sustainable and corrosion-resistant materials, such as hot-dip galvanized steel, stainless steel (304, 316, and even Duplex grades for highly corrosive environments), and fiberglass reinforced polyester (FRP) casings. These material selections are crucial for extending the service life of units, reducing maintenance requirements, and ensuring long-term reliability in harsh industrial settings. Furthermore, smart technology integration, including IoT-enabled monitoring systems and advanced control algorithms, is becoming standard. These systems provide real-time performance data, predictive maintenance alerts, and remote diagnostic capabilities, allowing operators to optimize the system's performance, identify potential issues before they become critical, and reduce downtime. The shift towards natural refrigerants like ammonia (NH3) and CO2 also profoundly impacts condenser design, requiring systems that can safely and efficiently handle higher pressures and specific thermodynamic properties. Manufacturers are investing heavily in R&D to develop compact, modular designs that facilitate easier installation, reduce footprint, and allow for scalability. For instance, some leading models now feature integrated water treatment systems to mitigate scaling and biological growth, further enhancing operational efficiency and reducing maintenance overhead. The global market for evaporative condensers is projected to grow steadily, driven by industrial expansion, particularly in emerging economies, and the replacement of older, less efficient cooling systems in developed markets. This growth is underpinned by the undeniable economic and environmental benefits offered by this technology compared to its conventional counterparts. The demand for bespoke solutions tailored to specific industrial processes, ambient conditions, and capacity requirements is also on the rise, pushing manufacturers to offer highly customizable units.

Operational Principles and Key Technical Parameters of Evaporative Condensers

At its core, the operation of an Evaporative Condenser is a masterclass in thermodynamic efficiency, leveraging the principle of latent heat of vaporization to achieve superior heat rejection. High-temperature, high-pressure refrigerant vapor from the compressor discharge enters the heat exchange coil located inside the condenser. Simultaneously, water is sprayed over the external surface of these coils, creating a thin film. A powerful fan draws ambient air upwards through the unit, causing a small portion of the recirculated water to evaporate. This evaporation process absorbs a significant amount of latent heat from the refrigerant inside the coils, leading to its condensation back into a liquid state. The non-evaporated water falls into a collection basin at the bottom of the unit and is recirculated. Key technical parameters define the performance and suitability of an evaporative condenser for a given application. These include the design wet-bulb temperature, which is the theoretical lowest temperature that can be achieved by evaporative cooling and is crucial for accurate sizing and performance prediction. Heat rejection capacity, measured in tons of refrigeration or kilowatts (kW), represents the total heat that the condenser can dissipate from the refrigerant. Airflow volume (CFM or m³/h) and fan motor power (kW) are critical for ensuring adequate air movement across the coils. Water circulation rate (GPM or m³/h) and pump motor power (kW) are essential for maintaining a continuous and uniform water film. Coil material (e.g., seamless steel tubes, stainless steel), fin type (if applicable, though typically bare tubes for most industrial applications), and surface area dictate the heat transfer characteristics. Furthermore, pressure drop across the coil, both for refrigerant and water circuits, is a vital consideration for system design and pump/compressor sizing. CTI (Cooling Technology Institute) certification is an industry benchmark for thermal performance, ensuring that units meet published ratings. Specific product specifications might include the overall dimensions, operating weight, shipping weight, and the sound power level (dBA) at a specified distance, all of which are important for site planning and regulatory compliance. Understanding these parameters, combined with detailed psychrometric analysis for specific geographic locations, enables engineers to precisely select and optimize an evaporative condenser for peak efficiency and reliability, ensuring that the total cost of ownership is minimized over the equipment’s lifecycle. The use of advanced computational fluid dynamics (CFD) modeling during the design phase further refines these parameters, optimizing airflow patterns and water distribution for maximum thermal performance and reduced drift loss.

Typical Evaporative Condenser Technical Specifications Table

| Parameter | Unit | Range/Typical Value | Notes |

|---|---|---|---|

| Heat Rejection Capacity | kW / Tons | 500 kW - 50,000 kW (150 - 15,000 Tons) | Varies significantly by model and application. |

| Design Wet-Bulb Temp. | °C / °F | 24°C - 32°C (75°F - 90°F) | Crucial for sizing, based on local climate data. |

| Airflow Volume | m³/h / CFM | 50,000 - 500,000 m³/h (30,000 - 300,000 CFM) | Influenced by fan type (axial/centrifugal) and motor size. |

| Fan Motor Power | kW | 7.5 kW - 100+ kW | Directly impacts energy consumption. |

| Water Flow Rate (Recirc.) | m³/h / GPM | 10 - 500 m³/h (45 - 2200 GPM) | Ensures optimal coil wetting. |

| Coil Material | Hot-dip Galvanized Steel, Stainless Steel (304/316/Duplex) | Corrosion resistance and heat transfer. | |

| Casing Material | Hot-dip Galvanized Steel, Stainless Steel, FRP | Durability and environmental resistance. | |

| Operating Weight | kg / lbs | 2,000 kg - 50,000+ kg (4,400 lbs - 110,000+ lbs) | Important for structural considerations. |

| Sound Level (1m) | dBA | 70 - 90 dBA (standard), | Consideration for noise-sensitive areas. |

Manufacturing Process and Uncompromising Quality Assurance

The production of a high-performance Evaporative Condenser is a complex process demanding meticulous attention to detail, advanced manufacturing techniques, and rigorous quality control at every stage. It begins with the selection of premium-grade materials, crucial for ensuring durability and resistance to corrosive environments common in industrial applications. For instance, the coil bundles, the heart of the condenser, are typically fabricated from seamless steel tubes (for ammonia systems) or stainless steel tubes (for Freon and other corrosive refrigerants), hot-dip galvanized after fabrication to provide a thick, uniform zinc coating for superior corrosion protection. This galvanization process, often adhering to ASTM A123 standards, ensures a projected service life exceeding 20 years for the coil. For the casing and structural components, options include heavy-gauge hot-dip galvanized steel, which undergoes a rigorous dipping process in molten zinc baths at temperatures around 450°C, ensuring a metallurgical bond and comprehensive coverage. Alternatively, stainless steel (SS304 or SS316) is often specified for highly corrosive environments, offering inherent resistance without external coatings. Fiberglass Reinforced Polyester (FRP) is another excellent material for basins and other non-structural components due to its lightweight, exceptional corrosion resistance, and low thermal conductivity. The manufacturing process involves several critical steps: precise tube bending and coil fabrication using CNC machines to ensure accurate dimensions and consistent pitch, followed by high-pressure hydrostatic testing (e.g., to 2.5 MPa) to confirm leak integrity. The structural framework involves precision cutting, welding (adhering to ASME Boiler and Pressure Vessel Code standards where applicable), and assembly, with critical weld joints undergoing non-destructive testing (NDT) like ultrasonic or radiographic inspection to detect any internal flaws. Fan assemblies, including motor mounting, shaft alignment, and blade balancing, are meticulously executed to minimize vibration and noise while maximizing airflow efficiency. Inspection standards are paramount throughout the entire manufacturing chain. This includes raw material inspection (material certificates), in-process quality checks (dimensional accuracy, weld integrity), and final performance testing. Adherence to international standards such as ISO 9001 for quality management systems, ANSI/ASHRAE Standard 140 for performance testing of HVAC equipment, and CTI standards for thermal performance verification is non-negotiable for reputable manufacturers. Each finished unit undergoes a comprehensive factory acceptance test (FAT), which may include simulated operational conditions to verify cooling capacity, power consumption, sound levels, and vibration. This multi-layered approach to manufacturing and quality assurance ensures that every evaporative condenser leaving the facility is not just a piece of equipment but a robust, high-performance asset designed for longevity and optimal operation in demanding industrial settings. This commitment to quality directly translates into reduced maintenance costs, minimal downtime, and superior return on investment for the end-user.

Technical Advantages and Unparalleled Performance Excellence

The inherent design of the Evaporative Condenser bestows a multitude of significant technical advantages over traditional air-cooled or water-cooled systems, making it the preferred choice for a wide array of industrial applications. Foremost among these is superior energy efficiency. By utilizing latent heat of vaporization, evaporative condensers can achieve condensing temperatures much closer to the ambient wet-bulb temperature, which is often 10-15°C lower than the dry-bulb temperature. This lower condensing temperature directly translates into reduced compressor head pressure, allowing the refrigeration compressor to operate more efficiently, consuming significantly less power. Studies by organizations like ASHRAE and the Cooling Technology Institute (CTI) consistently show energy savings of 15-25% compared to conventional systems. Furthermore, evaporative condensers offer exceptional heat transfer capabilities due to the high heat transfer coefficient of evaporating water. The spray water not only enhances heat exchange but also continuously washes the coil surface, preventing dry spots and ensuring optimal performance. Another key advantage is their remarkable water efficiency compared to once-through cooling systems; evaporative condensers operate in a recirculating loop, with water consumption primarily limited to evaporation, drift loss, and blowdown to manage water quality. Modern designs incorporate high-efficiency drift eliminators, typically reducing water drift to less than 0.001% of the circulating water flow, minimizing water loss. Corrosion resistance is another critical attribute, addressed through the use of hot-dip galvanized steel, stainless steel, and FRP materials for critical components, ensuring a long operational life even in corrosive industrial environments or areas with high atmospheric salinity. The closed-loop design of the refrigerant circuit also protects the compressor and other refrigeration components from airborne contaminants and scaling issues that can plague open cooling towers. The compact footprint of an evaporative condenser relative to its cooling capacity is also a significant benefit, especially for facilities with limited space. The modular design often allows for easier transportation, assembly, and future expansion. Advanced features like variable frequency drives (VFDs) for fans and pumps enable precise capacity control, further optimizing energy consumption and system performance during part-load conditions, which are common in many industrial processes. This flexibility in operation allows for fine-tuning the system to match varying cooling loads, maximizing efficiency throughout the year. The robust construction, coupled with sophisticated control systems, results in reduced maintenance requirements and lower overall operational costs throughout the system's extended service life, making the Evaporative Condenser a truly economically viable and environmentally responsible choice for demanding industrial refrigeration needs.

Diverse Application Scenarios and Industry-Specific Solutions

The versatility and efficiency of the Evaporative Condenser make it an ideal choice for a remarkably broad spectrum of industrial applications, spanning critical sectors where precise temperature control and reliable heat rejection are paramount. In the petrochemical industry, these condensers are essential for cooling large process streams, condensing hydrocarbon vapors, and maintaining stable operating temperatures for reactors and distillation columns. Their ability to handle high heat loads efficiently contributes significantly to process optimization and safety. Similarly, in the metallurgical industry, particularly for steel manufacturing, aluminum production, and metal casting, evaporative condensers are deployed to cool induction furnaces, quench tanks, and continuous casting machines, managing the immense heat generated during these high-temperature processes. For the burgeoning data center industry, where massive heat loads from servers require constant and efficient removal, evaporative condensers provide a cost-effective and energy-efficient solution, supporting mission-critical operations and reducing power usage effectiveness (PUE). The food and beverage sector relies heavily on these units for cold storage, blast freezing, and process cooling in dairies, breweries, and meat processing plants, ensuring product quality and safety by maintaining precise refrigeration temperatures. In the pharmaceutical and chemical industries, evaporative condensers are critical for maintaining specific reaction temperatures, condensing solvents, and cooling production lines, often requiring specialized materials like stainless steel coils for chemical compatibility and purity standards. The power generation industry, including conventional thermal power plants and renewable energy facilities, utilizes these condensers for turbine exhaust condensation, improving cycle efficiency and reducing water consumption compared to once-through cooling systems. Furthermore, in HVAC systems for large commercial buildings, airports, and exhibition centers, evaporative condensers provide high-efficiency heat rejection for chillers, contributing to significant operational savings and a reduced carbon footprint. Municipal water supply and drainage systems also utilize these condensers in various treatment processes where heat removal is necessary. The adaptability of the Evaporative Condenser extends to its ability to be customized for specific refrigerants (ammonia, R-22, R-134a, R-404A, etc.), varying ambient conditions, noise level requirements (e.g., low-noise configurations for urban areas), and footprint constraints. For instance, in an ammonia refrigeration system for a large cold storage warehouse, the evaporative condenser not only condenses ammonia vapor but also operates at lower condensing pressures, which enhances the coefficient of performance (COP) of the overall refrigeration cycle, leading to substantial electricity savings. This broad applicability, coupled with the potential for significant energy savings and operational reliability, solidifies the evaporative condenser's position as a cornerstone technology in modern industrial infrastructure.

Manufacturer Comparison and Informed Selection Criteria

Selecting the right manufacturer for an Evaporative Condenser is a strategic decision that profoundly impacts the long-term performance, reliability, and total cost of ownership of an industrial refrigeration system. The market offers a diverse range of suppliers, each with varying levels of expertise, manufacturing capabilities, and product offerings. When evaluating potential manufacturers, several critical criteria should guide the decision-making process. Firstly, assess their experience and specialization in evaporative cooling technology, particularly in B2B industrial applications. A manufacturer with a proven track record of over 20 years, for example, often indicates deep industry knowledge and robust engineering capabilities. Secondly, scrutinize the quality of materials and manufacturing processes. As discussed, the use of hot-dip galvanized steel, stainless steel, and high-quality FRP, coupled with certifications like ISO 9001, ASME, and CTI, are indicators of superior product quality and adherence to international standards. Be wary of manufacturers offering significantly lower prices that may compromise on material thickness, coating quality, or internal component specifications. Thirdly, evaluate thermal performance ratings and energy efficiency data. Reputable manufacturers will provide detailed performance curves, power consumption figures, and CTI certification, ensuring the unit will meet specified cooling loads under diverse operating conditions. Requesting third-party verified test data adds an extra layer of confidence. Fourthly, consider the customization capabilities. Industrial applications often have unique requirements concerning capacity, footprint, noise levels, and specific refrigerant types. A manufacturer capable of providing tailored solutions rather than off-the-shelf products demonstrates a higher level of engineering flexibility and customer focus. Fifthly, assess the manufacturer's after-sales support, including installation guidance, spare parts availability, warranty provisions, and technical assistance. A robust support network is crucial for minimizing downtime and ensuring the long-term operational integrity of the unit. Finally, examine customer testimonials, case studies, and industry references. Engaging with existing clients can provide invaluable insights into the manufacturer's reliability, product performance, and responsiveness. While comparing various brands, it's beneficial to analyze specific models based on their heat rejection capacity per unit of fan power, specific water consumption rates, and maintenance accessibility. For instance, some manufacturers might offer modular designs that simplify transport and installation, while others might prioritize advanced corrosion protection systems for extreme environments. Investing in a quality Evaporative Condenser from a reputable manufacturer ensures not only optimal refrigeration performance but also a reduced risk of premature failure, costly repairs, and operational inefficiencies, providing substantial long-term value.

Evaporative Condenser Manufacturer Comparison Overview

| Feature | Manufacturer A (Premium) | Manufacturer B (Mid-Range) | Manufacturer C (Budget) |

|---|---|---|---|

| Typical Material (Coil) | Hot-dip Galvanized Steel (Seamless), SS304/SS316 Options | Hot-dip Galvanized Steel | Pre-galvanized Steel or Thin Galvanized |

| Casing Material | Heavy Gauge HDG, SS304/FRP Basins | HDG, some FRP components | Light Gauge HDG |

| Certifications | CTI Certified, ISO 9001, ASME, CE | ISO 9001, some regional certifications | Basic factory certification |

| Energy Efficiency | Excellent (Low Fan/Pump Power per Ton) | Good | Moderate |

| Customization | High (Tailored capacity, noise, footprint) | Moderate (Standard models with options) | Low (Standard sizes only) |

| Service Life (Estimated) | 20+ Years | 10-15 Years | 5-10 Years |

| After-sales Support | Global network, comprehensive support, readily available parts | Regional support, standard parts availability | Limited, slow parts delivery |

| Typical Price Point | High | Medium | Low |

Customized Solutions and Advanced Engineering Capabilities

In the demanding realm of industrial refrigeration, off-the-shelf solutions often fall short of meeting the precise and unique requirements of complex operational environments. This is where the ability to provide customized Evaporative Condenser solutions becomes a crucial differentiator for leading manufacturers. A truly client-centric approach involves a deep understanding of the client's specific process, existing infrastructure, local climate data, and long-term operational goals. This typically begins with a detailed engineering consultation, where experts collaborate with the client's technical team to define the exact cooling load, desired condensing temperatures, available footprint, noise constraints, and water quality characteristics. Based on this comprehensive assessment, advanced engineering capabilities come into play. This includes leveraging sophisticated software for thermal modeling (e.g., using ANSYS Fluent for CFD analysis), structural analysis (FEA - Finite Element Analysis for vibration and wind load calculations), and acoustic simulations to design a condenser that is perfectly optimized for the application. Customization can involve significant modifications to standard designs, such as adapting unit dimensions to fit confined spaces, designing for extremely high or low ambient temperatures, or incorporating specialized coil materials (e.g., Duplex stainless steel for highly corrosive refrigerants or brackish water environments). Furthermore, specific requirements for modularity, ease of assembly, and maintenance access can be integrated into the design, reducing installation time and future operational costs. For instance, a food processing plant might require a condenser with specific hygiene features, while a power plant might need one optimized for extremely high thermal loads and continuous operation in a remote location. Leading manufacturers also offer flexible power configurations, accommodating various voltage requirements and integrating variable frequency drives (VFDs) for fans and pumps to maximize energy savings during partial load conditions. Beyond the physical unit, customized solutions extend to control systems, offering bespoke PLC programming, integration with existing SCADA systems, and specialized sensors for enhanced monitoring and automation. This level of tailoring ensures that the installed Evaporative Condenser not only meets but often exceeds performance expectations, delivering optimal efficiency and reliability throughout its service life. This holistic approach, from initial concept to post-installation support, underscores the value of partnering with a manufacturer possessing extensive engineering prowess and a commitment to delivering truly bespoke, high-performance cooling solutions that align perfectly with the client's strategic objectives.

Real-World Case Studies and Proven Implementations

The true testament to the efficacy and reliability of an Evaporative Condenser lies in its successful implementation across diverse industrial settings. Numerous real-world applications underscore the significant operational advantages and energy savings achieved through this technology. For instance, a large-scale cold storage and logistics hub in the Midwest, spanning over 500,000 square feet, faced challenges with high energy consumption from its existing air-cooled refrigeration system. Upon consulting with our engineering team, they opted to replace their outdated condensers with three high-capacity evaporative condensers. The result was a documented 22% reduction in annual energy costs, translating to over $300,000 in savings annually, along with a more stable and lower condensing pressure for their ammonia refrigeration system, improving overall system reliability and product preservation. This project showcased the economic viability and performance consistency over various seasonal ambient temperatures. In another instance, a major chemical manufacturing facility in a humid coastal region required a robust cooling solution for a new process line that generated a substantial heat load. Traditional water-cooled systems were deemed inefficient due to high water treatment costs and regulatory discharge limits. An custom-designed Evaporative Condenser with stainless steel coils and FRP casing was installed, specifically engineered to withstand the corrosive coastal atmosphere and handle the unique chemical process requirements. This solution not only met the stringent heat rejection targets but also demonstrated excellent resistance to external corrosion, projected to extend the unit's lifespan by an additional 10 years beyond standard expectations, and minimized chemical treatment costs through an integrated water quality management system. A third notable case involves a large-scale meat processing plant that needed to upgrade its refrigeration infrastructure to meet increasing production demands and comply with stricter environmental regulations regarding water usage. By integrating an advanced evaporative condenser, the plant achieved a 15% improvement in their specific energy consumption per ton of refrigeration, alongside a remarkable 30% reduction in water consumption compared to their previous system due to highly efficient drift eliminators and intelligent blowdown control. Customer feedback from these projects consistently highlights the robust construction, ease of maintenance access, and the professionalism of the installation and commissioning teams. These case studies, alongside dozens of others across petrochemical, metallurgical, and HVAC industries globally, collectively demonstrate that strategic investment in high-quality Evaporative Condenser technology delivers tangible benefits in terms of reduced operational costs, enhanced system reliability, and improved environmental performance. Our extensive portfolio of successful projects, spanning various industries and geographical locations, stands as a testament to our profound expertise and commitment to delivering superior cooling solutions tailored to each client's unique needs. Each project undergoes rigorous planning and execution, ensuring seamless integration and optimal performance from day one.

After-Sales Support, Trustworthiness, and Long-Term Partnership

The decision to invest in an industrial Evaporative Condenser is a long-term commitment, and the reliability of the supplier's after-sales support is as critical as the quality of the product itself. A trustworthy manufacturer understands that the relationship extends far beyond the point of sale, encompassing comprehensive support throughout the product's entire lifecycle. This begins with transparent delivery schedules, where project timelines are meticulously planned and communicated, ensuring that the condenser arrives on-site as promised, minimizing construction delays and allowing for efficient project management. A typical delivery period for standard units might range from 8-12 weeks, with customized solutions requiring additional time depending on complexity, all clearly outlined in the contractual agreement. Upon delivery, comprehensive installation guidance is provided, often accompanied by on-site technical supervision or detailed manuals and drawings to ensure correct assembly and commissioning. Crucially, a robust warranty commitment offers peace of mind; standard warranties typically cover parts for 12-18 months from commissioning or 24 months from shipment, protecting against manufacturing defects and ensuring operational integrity. Beyond the warranty period, availability of genuine spare parts is paramount. Leading manufacturers maintain extensive inventories of critical components, ensuring rapid dispatch to minimize downtime during maintenance or unexpected repairs. Customer support extends to a dedicated technical assistance team, accessible for troubleshooting, operational advice, and performance optimization queries. This often includes remote diagnostic capabilities through integrated smart systems, allowing for proactive identification of potential issues before they escalate. Regular maintenance programs, including scheduled inspections and preventative service, can also be offered to maximize the unit's efficiency and extend its service life. The focus on long-term partnership means anticipating client needs, providing training for operational staff, and offering upgrade paths as technology evolves or operational requirements change. This unwavering commitment to support builds deep trust and reinforces the decision to choose a particular supplier. Clients who experience seamless project execution, responsive technical support, and transparent communication are far more likely to forge lasting partnerships, which is a testament to a manufacturer's trustworthiness and dedication to customer success. Our commitment spans decades, with a focus on building relationships through consistent performance and unparalleled service, ensuring that your investment in an Evaporative Condenser delivers continuous value for years to come.

Frequently Asked Questions (FAQ) about Evaporative Condensers

Q1: What are the primary energy savings associated with an Evaporative Condenser compared to an air-cooled condenser?

A1: Evaporative condensers leverage the wet-bulb temperature, which is inherently lower than the dry-bulb temperature (ambient air temperature). This allows for lower condensing temperatures for the refrigerant, resulting in significantly reduced compressor work and 15-25% energy savings compared to air-cooled condensers, especially in regions with high ambient dry-bulb temperatures but moderate wet-bulb temperatures.

Q2: How does an Evaporative Condenser manage water consumption and potential scaling issues?

A2: Water is consumed primarily through evaporation (the heat rejection mechanism) and a small amount of drift loss. Modern units incorporate high-efficiency drift eliminators to minimize drift to less than 0.001% of circulating water. To prevent scaling and biological growth, a portion of the recirculating water (blowdown) is continuously drained and replaced with fresh makeup water. Water treatment systems, including filters, softeners, and chemical dosing, are often integrated to maintain water quality and extend unit life. Our units are designed for easy access for cleaning and maintenance, further mitigating scaling risks.

Q3: What are the typical service life expectations for an Evaporative Condenser, and what factors influence it?

A3: With proper maintenance and water treatment, a high-quality evaporative condenser constructed with hot-dip galvanized steel or stainless steel components can have a service life of 20 years or more. Factors influencing longevity include material quality (e.g., thickness of galvanization, grade of stainless steel), water quality management, ambient environmental conditions (e.g., corrosive atmosphere), maintenance frequency, and operational load profiles. Our robust designs prioritize long-term durability.

Q4: Are Evaporative Condensers suitable for all types of refrigerants?

A4: Yes, evaporative condensers are highly versatile and can be designed for use with a wide range of common industrial refrigerants, including ammonia (NH3), Freon (HFCs like R-22, R-134a, R-404A, R-507), and increasingly, natural refrigerants like CO2. The selection of coil material (e.g., seamless steel for ammonia, stainless steel for specific Freons or corrosive applications) and pressure rating are customized to suit the specific refrigerant and operating conditions, ensuring optimal safety and performance. We offer tailored solutions to match your refrigerant requirements.

Conclusion and Future Outlook for Evaporative Condensers

The Evaporative Condenser stands as a pivotal technology in the landscape of industrial refrigeration and process cooling, offering an unparalleled combination of energy efficiency, robust performance, and environmental responsibility. Its ability to achieve lower condensing temperatures compared to dry-cooled alternatives directly translates into substantial energy savings for compressors, thereby reducing operational costs and carbon footprints for industrial facilities across diverse sectors. From petrochemical and metallurgical plants to food processing and data centers, the versatility and adaptability of evaporative condensers make them an indispensable asset for managing significant heat loads efficiently. The continued evolution of this technology, driven by innovations in material science, advanced manufacturing techniques like precision CNC fabrication and robust hot-dip galvanization, and the integration of smart control systems, promises even greater efficiencies and extended service life in the future. As industries worldwide face increasing pressure to adopt sustainable practices and optimize resource consumption, the demand for high-performance, reliable, and customizable evaporative condensers is set to grow exponentially. Investing in these advanced cooling solutions is not merely an expenditure but a strategic decision that delivers significant long-term returns through reduced energy consumption, minimal maintenance, and enhanced operational reliability. Manufacturers committed to rigorous quality assurance, continuous R&D, and comprehensive after-sales support will lead this transition, ensuring that businesses can confidently meet their cooling demands while adhering to stringent environmental regulations. The future of industrial cooling is intrinsically linked to technologies that offer both economic viability and ecological stewardship, and the Evaporative Condenser is perfectly positioned at the forefront of this evolution, poised to support the next generation of efficient and sustainable industrial operations.

References & Further Reading

- ASHRAE Standards and Guidelines for HVAC&R Systems.

- Cooling Technology Institute (CTI) - Performance and Best Practices.

- International Organization for Standardization (ISO) - ISO 9001 Quality Management.

- ASME Boiler and Pressure Vessel Code (BPVC) Standards.

- U.S. Department of Energy - Evaporative Condensers: Opportunities for Energy Savings in Industrial Refrigeration.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China