We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

In the realm of industrial refrigeration and air conditioning, the search for highly efficient and environmentally conscious heat rejection solutions is ceaseless. Among the most pivotal innovations in this domain is the Evaporative Condenser. This advanced heat exchanger plays a crucial role in various industrial processes by effectively rejecting heat from refrigerant gases to the atmosphere, offering superior performance compared to traditional air-cooled or water-cooled systems. This comprehensive guide delves into the intricate workings, technological advancements, diverse applications, and inherent advantages of the Evaporative Condenser, providing an in-depth understanding for engineers, facility managers, and industry professionals alike.

Understanding the Evaporative Condenser: Core Principles and Industry Trends

An Evaporative Condenser is a specialized type of heat exchanger that combines the principles of a cooling tower and a shell-and-tube condenser. It uses the latent heat of vaporization of water to achieve highly efficient heat rejection. Hot refrigerant vapor from the compressor enters the coil, which is continuously wetted by a spray of recirculating water. Air is simultaneously drawn or forced over the wetted coils, causing a small portion of the water to evaporate. This evaporation process absorbs a significant amount of heat from the refrigerant inside the coils, leading to its condensation. The cooled refrigerant then flows back to the expansion valve, completing the refrigeration cycle.

Current Industry Trends and Market Dynamics

- Energy Efficiency Mandates: Global regulations are increasingly stringent regarding energy consumption. The Evaporative Condenser's ability to achieve lower condensing temperatures than air-cooled units directly translates to reduced compressor power consumption, making it a preferred choice for sustainable operations.

- Water Conservation Technologies: While evaporative units use water, advancements in drift eliminators, intelligent blowdown controls, and hybrid designs are significantly reducing water consumption, addressing environmental concerns.

- Material Innovation: The shift towards more durable, corrosion-resistant materials like FRP (Fiber Reinforced Polymer) for casing and high-grade stainless steel for coils is extending product lifespan and reducing maintenance needs.

- Smart Integration & IoT: Modern Evaporative Condenser units are increasingly equipped with sensors and control systems, enabling remote monitoring, predictive maintenance, and optimized performance through IoT platforms.

- Modular Designs: For ease of transport, installation, and scalability, modular Evaporative Condenser designs are gaining popularity, allowing for quick deployment and future expansion.

Detailed Technical Parameters and Specifications of Evaporative Condenser

Selecting the right Evaporative Condenser requires a thorough understanding of its technical specifications. These parameters dictate the unit's capacity, efficiency, and suitability for specific applications. Below is a comprehensive table outlining typical ranges for key parameters. It's important to note that actual values will vary based on manufacturer, model, and design intent.

Key Evaporative Condenser Parameters Table

| Parameter | Description | Typical Range / Unit |

|---|---|---|

| Heat Rejection Capacity | The amount of heat the condenser can reject from the refrigerant. Measured in Refrigeration Tons (TR) or Kilowatts (kW). | 50 TR - 2000 TR (175 kW - 7000 kW) per unit |

| Refrigerant Type | Common refrigerants it can condense. | Ammonia (NH3), Freon (R134a, R404A, R507), CO2 |

| Condensing Temperature | Target temperature of the condensed refrigerant. Ideally close to the wet-bulb temperature for maximum efficiency. | 30°C - 45°C (significantly lower than ambient dry bulb) |

| Approach Temperature | Difference between leaving water temperature and wet-bulb temperature. A lower approach indicates higher efficiency. | 3°C - 8°C (lower is better for efficiency) |

| Air Flow Rate | Volume of air moved through the condenser by fans. Crucial for effective heat and mass transfer. | 50,000 m³/h - 500,000 m³/h |

| Water Flow Rate (Circulating) | Volume of water recirculated over the coils via the spray system. Essential for continuous wetting and evaporative cooling. | 10 m³/h - 500 m³/h |

| Evaporation Rate | The rate at which water is consumed due to evaporation for cooling. This is the primary mechanism of heat rejection. | 0.005 - 0.01 kg of water per 1000 BTU/hr of heat rejected |

| Fan Type | The type of fan used to draw or force air through the unit. | Axial (Propeller) or Centrifugal fan. Axial (Induced Draft/Forced Draft) preferred for large units due to efficiency. |

| Fan Motor Power | Power consumption of the fan motor. Directly impacts operating costs. | 5 kW - 100 kW+ |

| Pump Motor Power | Power consumption of the water pump motor. Circulates water to spray nozzles. | 1.5 kW - 20 kW |

| Coil Material | Material of the heat exchange coils. Must resist corrosion and be compatible with the refrigerant. | Seamless Steel Hot-Dip Galvanized, Stainless Steel (304/316L) |

| Casing Material | External structural material. Provides structural integrity and corrosion protection. | Hot-Dip Galvanized Steel, Stainless Steel, FRP (Fiber Reinforced Polymer) |

| Noise Level | Acoustic output during operation. Important for urban or noise-sensitive installations. | 65 dB(A) - 85 dB(A) (at 1m distance, can be lower with noise attenuation options) |

| Footprint / Dimensions | Physical space occupied by the unit. Crucial for site planning. | Variable, e.g., 3m x 2m x 4m (L x W x H) for medium units, larger for high capacity. |

| Operating Weight | Weight of the unit when filled with water and refrigerant. Important for structural load calculations. | Typically 5,000 kg - 50,000 kg+ |

| Lifespan | Expected operational life of the unit under proper maintenance. | 15-25 years, depending on maintenance and material selection. |

| Compliance Standards | Industry certifications and standards the unit adheres to. | ISO 9001, CE, ASME, CTI (Cooling Technology Institute) |

The Meticulous Manufacturing Process of an Evaporative Condenser

The manufacturing of an Evaporative Condenser is a complex process demanding precision engineering, high-quality materials, and rigorous testing to ensure optimal performance, durability, and safety. Longxuan FRP's commitment to excellence is reflected in every stage of our production, adhering to international standards such as ISO 9001 for quality management and ANSI standards for specific component design.

Process Flow Explained: From Design to Delivery

The manufacturing journey typically involves several critical stages, ensuring each Evaporative Condenser meets the highest quality benchmarks. While a detailed visual diagram would best illustrate this, here's a textual breakdown of the key steps:

-

1. Design & Engineering

The initial and foundational phase involves extensive CAD (Computer-Aided Design) and CFD (Computational Fluid Dynamics) simulations. These advanced tools are utilized to meticulously optimize the unit's thermal performance, airflow dynamics, water distribution patterns, and structural integrity. This stage meticulously considers client-specific heat load requirements, ambient environmental conditions (e.g., wet-bulb temperatures), and the type of refrigerant being condensed. Material selection, a crucial aspect for longevity and performance, is finalized here – for instance, specifying hot-dip galvanized steel for structural components, high-grade stainless steel for corrosion-prone areas like coils, or durable Fiber Reinforced Polymer (FRP) for the casing. All designs are rigorously checked for compliance with relevant industry codes and standards, including ASME for pressure vessels (pertaining to the coil integrity) and CTI for thermal performance validation, ensuring the design meets or exceeds industry best practices.

-

2. Material Preparation & Coil Fabrication

This stage commences with the procurement of high-grade raw materials. For coils, seamless steel tubing, either carbon steel destined for hot-dip galvanizing or 304/316L stainless steel for superior corrosion resistance, is precisely cut to length. These tubes then undergo advanced CNC (Computer Numerical Control) bending processes. This ensures the coils are formed into optimal serpentine or spiral configurations, maximizing the surface area available for heat exchange and promoting efficient refrigerant flow. The precision of CNC machining minimizes material waste and ensures consistent product quality. Welding processes for coil headers and connections, critical for pressure integrity, strictly adhere to industry benchmarks such as AWS (American Welding Society) standards, with skilled technicians performing these crucial joining tasks.

-

3. Hot-Dip Galvanizing & Surface Treatment (for Steel Components)

For steel structural components and carbon steel coils, a comprehensive surface preparation is undertaken, involving thorough cleaning and pickling to remove impurities. Following this, components are immersed in baths of molten zinc in a process known as hot-dip galvanizing. This critical step, which strictly conforms to ASTM A123/A153 standards, applies a robust, multi-layer metallic coating that offers unparalleled corrosion protection against the typically harsh, humid, and chemically exposed environments found in industrial settings. This protective layer significantly extends the unit's operational lifespan. For Evaporative Condenser models utilizing FRP, the panels are precisely molded using high-strength resins combined with fiberglass, ensuring exceptional chemical resistance, UV stability, and long-term durability without the need for traditional galvanization.

-

4. Casing and Structure Manufacturing

The external casing and the supporting structural framework are meticulously fabricated from either hot-dip galvanized steel, stainless steel, or high-grade FRP, depending on the specific model and application requirements. Precision cutting, accurate bending, and high-quality welding techniques (for steel components) or advanced molding processes (for FRP components) are rigorously applied. Every element, from the robust fan deck and efficient air inlet louvers to the resilient water basin, is manufactured to ensure superior airtightness, exceptional structural rigidity, and optimal thermal performance. Many larger units are designed with modular construction in mind, which greatly facilitates easier and more cost-effective transportation, as well as streamlined on-site assembly, reducing installation time and complexity.

-

5. Assembly & Internal Components Integration

During the assembly phase, the pre-fabricated heat exchange coils are carefully positioned and secured within the condenser casing. This step is followed by the meticulous integration of all other critical internal components. This includes the installation of the fan assembly (either high-efficiency axial or centrifugal fans), the complete water distribution system (comprising precise spray nozzles and robust header pipes), highly effective drift eliminators designed to minimize water loss, and the sump/basin. Electrical wiring for motors and control systems is expertly routed and connected, adhering to stringent electrical safety codes and standards to ensure reliable and safe operation of the entire Evaporative Condenser unit.

-

6. Quality Control & Performance Testing

Before any Evaporative Condenser unit leaves our facility, it undergoes an exhaustive and rigorous battery of quality control checks and performance tests. This multi-faceted testing regimen is designed to ensure that every unit not only meets but often exceeds design specifications and international performance standards. Key tests include:

- Hydrostatic Testing: Coils are subjected to high-pressure water testing to detect even the minutest leaks, guaranteeing the integrity of the refrigerant circuit under all operational pressures.

- Airflow Testing: Fans are operated to verify that the actual airflow rates match the design specifications, ensuring optimal heat transfer.

- Water Distribution Uniformity: The spray system is activated and meticulously checked for uniform water coverage over the entire coil surface, which is critical for efficient evaporation.

- Electrical Testing: Comprehensive checks are performed on all motors, wiring, and control panels to confirm correct operation, adherence to safety standards, and proper functionality.

- Sound Level Measurement: Noise emissions are precisely measured to ensure compliance with specified noise limits, especially important for installations in noise-sensitive areas.

- Visual Inspection: A final, thorough visual inspection is conducted to identify any manufacturing defects, assess the quality of protective coatings, and ensure the overall fit and finish of the unit.

-

7. Packaging & Shipping

Upon successful completion of all quality checks, the Evaporative Condenser units are meticulously prepared for shipment. For larger models, units are often disassembled into manageable sections to optimize transport efficiency and reduce shipping costs. Each component is carefully packaged and secured to prevent any damage during transit, ensuring it arrives at the client's site in pristine condition. Comprehensive installation manuals, detailed operational guides, and maintenance instructions are provided with every shipment, empowering clients with the necessary information for smooth commissioning, effective operation, and long-term maintenance of their new Evaporative Condenser.

Strategic Application Scenarios for the Evaporative Condenser

The versatility and high efficiency of the Evaporative Condenser make it an indispensable component across a wide array of industrial and commercial applications. Its ability to achieve lower condensing temperatures than air-cooled counterparts, especially in warmer climates, translates directly into significant energy savings for the entire refrigeration or HVAC system. Below are some primary application sectors:

-

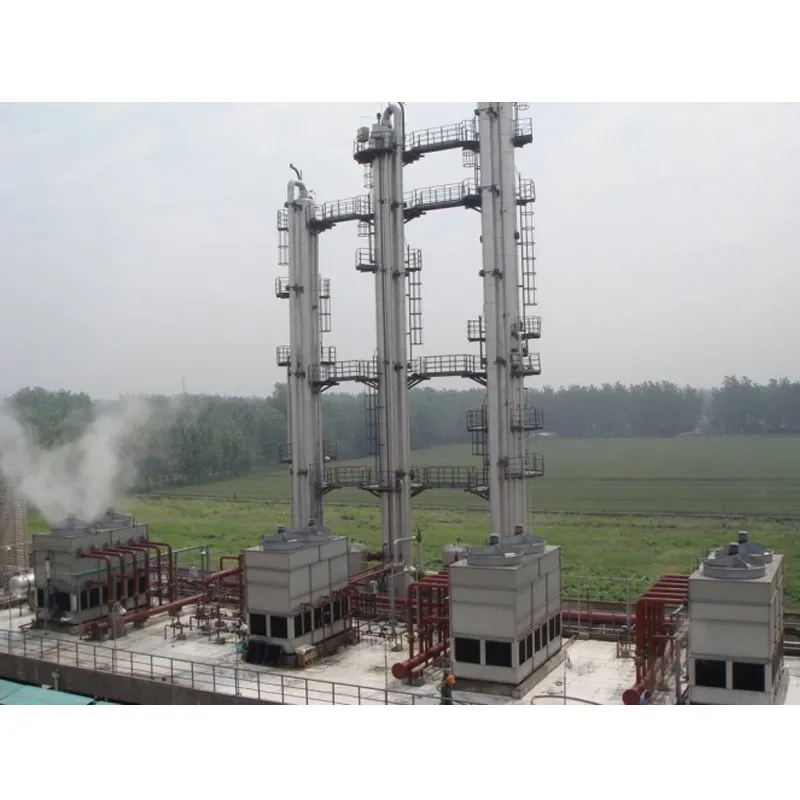

Petrochemical Industry

In petrochemical plants, cooling large volumes of process fluids and condensing various gases are critical for safe and efficient operations. Evaporative Condensers are widely used for ammonia refrigeration systems, hydrocarbon cooling, and other demanding process heat rejection needs. Their robust construction and selection of corrosion-resistant materials are absolutely vital in these challenging and often chemically aggressive environments. The exceptional energy efficiency of these units contributes significantly to the overall profitability and environmental compliance of these energy-intensive industrial operations.

-

Metallurgy and Steel Manufacturing

Steel mills and metallurgical facilities are inherently high-temperature environments that generate immense amounts of heat, requiring robust cooling solutions. Evaporative Condensers are extensively employed to cool critical equipment such as induction furnaces, rolling mills, and continuous casting machines. They provide reliable and consistent cooling for process water, which in turn reduces thermal stress on expensive machinery, prevents overheating, and ensures the continuous, uninterrupted operation of production lines. The durable construction and specialized coatings of these condensers are designed to withstand the harsh conditions prevalent in these industries, including high dust levels and elevated ambient temperatures.

-

Food & Beverage Processing

For the food and beverage industry, spanning from meat processing to dairy production and brewing, precise and consistent temperature control is paramount for ensuring product safety, maintaining quality, and extending shelf life. Evaporative Condensers are essential components in large-scale refrigeration systems, including cold storage warehouses, rapid blast freezers, and process chillers. Their high efficiency ensures that perishable goods are kept at optimal storage and processing temperatures with minimal energy expenditure, directly translating to reduced spoilage and significant operational cost savings for producers.

-

Power Generation

In power plants, both conventional thermal power stations and emerging renewable energy facilities, efficient heat rejection is fundamental to the operational cycle and overall plant efficiency. While large cooling towers are commonly used for turbine exhaust condensation, Evaporative Condensers find application in auxiliary cooling loads or for specific process fluid cooling, such as transformer oil cooling or closed-loop cooling for specialized equipment. Their high efficiency contributes to improving the overall plant heat rate and significantly reducing operating costs, supporting more sustainable power production.

-

Chemical and Pharmaceutical Industries

Chemical processes frequently involve exothermic reactions that necessitate precise and stable temperature control to ensure product purity and prevent runaway reactions. Similarly, pharmaceutical manufacturing relies heavily on stable temperatures for product quality, stability, and safety, especially in cleanroom environments. Evaporative Condensers provide efficient and reliable cooling for critical applications like reactor cooling, solvent recovery processes, and general HVAC for controlled environments. Their inherent closed-loop design on the refrigerant side offers an added layer of protection against contamination, which is crucial in these highly sensitive industries.

-

HVAC and Data Centers

For large commercial buildings, expansive airport complexes, and particularly for modern data centers, maintaining optimal indoor temperatures and reliably cooling vast IT infrastructure is absolutely vital for operational continuity and data integrity. Evaporative Condensers are integral components in large central chilling plants, offering a significantly more energy-efficient solution for heat rejection compared to conventional air-cooled chillers. This translates directly into substantial operational cost savings due to reduced electricity consumption, a critical factor for the massive energy demands of data centers, where even a slight improvement in Power Usage Effectiveness (PUE) can lead to enormous savings.

-

Plastics and Rubber Industry

Molding, extrusion, and calendering processes within the plastics and rubber industries generate considerable amounts of heat, which must be efficiently removed to maintain product quality and optimize production cycles. Evaporative Condensers are crucial for cooling the hydraulic oil of injection molding machines, process water for extruders, and chill rolls used in film and sheet production. By providing consistent cooling, they ensure stable production cycles, prevent equipment overheating, and contribute to the extended operational life of expensive machinery.

-

Marine and Offshore Applications

For marine and offshore environments, which present some of the most challenging operating conditions, robust and highly corrosion-resistant Evaporative Condensers are often employed. These units typically feature specialized coatings, marine-grade stainless steel components, and compact designs to suit the limited space onboard large vessels, oil rigs, and offshore platforms. They provide reliable cooling for HVAC systems, process cooling, and critical machinery, ensuring continuous operation despite severe environmental factors such as saltwater exposure, high humidity, and strong winds.

Unmatched Technical Advantages of the Evaporative Condenser

The widespread adoption of Evaporative Condenser technology is primarily driven by its significant technical and operational advantages over other heat rejection methods. These benefits contribute to lower operating costs, enhanced system performance, and a reduced environmental footprint, making them a preferred choice for numerous industrial and commercial applications.

Superior Energy Efficiency

One of the most compelling advantages of an Evaporative Condenser is its remarkably high energy efficiency. This is achieved by expertly leveraging the latent heat of vaporization of water, allowing these units to reach condensing temperatures significantly lower than the ambient dry-bulb temperatures, often approaching the much cooler wet-bulb temperature. This critical ability to achieve lower condensing pressures directly translates into a substantial reduction in the work required by the compressor, leading to impressive savings in power consumption. Typically, an Evaporative Condenser can reduce compressor power consumption by 10-20% when compared to conventional air-cooled condensers, and even offer up to 5% better performance than combined cooling tower/shell-and-tube condenser setups. Such efficiency gains directly translate into lower electricity bills, substantial operational cost savings, and a significantly smaller carbon footprint, aligning perfectly with modern sustainability goals.

Reduced Water Consumption (Compared to Once-Through Systems)

While an Evaporative Condenser does utilize water, it does so with far greater efficiency than antiquated once-through cooling systems. In an evaporative condenser, water is continuously recirculated, and only a small fraction is consumed through evaporation (the primary cooling mechanism), drift (minute water droplets carried out by airflow), and blowdown (controlled removal of concentrated water to prevent mineral buildup). Modern units are equipped with highly efficient drift eliminators, which can reduce drift loss to less than 0.001% of the total circulating water flow. Furthermore, intelligent blowdown controls precisely manage water quality, minimizing wastage. This makes them a responsible and preferred choice in regions where water conservation is a critical environmental or economic concern. Compared to traditional once-through cooling systems, water consumption can be reduced by over 95%, making it a highly sustainable option.

Compact Footprint and Installation Flexibility

A significant advantage of the Evaporative Condenser lies in its integrated design, which ingeniously combines the functionalities of both a cooling tower and a heat exchanger into a single, cohesive unit. This ingenious integration results in a significantly more compact footprint compared to a traditional setup involving separate cooling towers and shell-and-tube condensers, thereby saving valuable plant space. This space-saving attribute is particularly beneficial in urban environments where real estate is at a premium, or within existing industrial facilities where space optimization is critical. Moreover, their typically modular design facilitates easier transportation, quicker on-site assembly, and greater installation flexibility, allowing for more streamlined project timelines and reduced labor costs.

Enhanced System Durability and Longevity

High-quality Evaporative Condenser units, particularly those manufactured using premium materials such as hot-dip galvanized steel or durable stainless steel components, complemented by robust FRP (Fiber Reinforced Polymer) casing, are engineered for exceptional resilience. They are meticulously built to withstand the rigorous demands of harsh industrial operating conditions, including varying temperatures, humidity, and exposure to various chemicals. Advanced manufacturing processes, including precision CNC machining for component accuracy and stringent welding protocols for structural integrity, ensure a long operational life, typically ranging from 15 to 25 years with diligent and proper maintenance. This inherent durability translates into a reduced need for frequent replacements and associated capital expenditures, offering a superior return on investment over the long term.

Corrosion Resistance

Given the continuous exposure to both water and air, corrosion resistance is an absolutely paramount factor in the design and longevity of an Evaporative Condenser. Leading manufacturers prioritize the employment of superior materials such as hot-dip galvanized steel (often further enhanced with additional epoxy coatings for extreme environments), high-grade 304/316L stainless steel for critical components like coils and internal water management systems, and high-strength FRP for the casing and water basin. These materials are specifically selected for their proven and exceptional resistance to rust, chemical attack, and environmental degradation. This meticulous material selection ensures long-term, reliable performance, minimizes the need for premature replacements, and significantly reduces ongoing maintenance requirements associated with corrosion.

Reduced Maintenance Requirements

While regular and proactive maintenance remains essential for the optimal functioning and extended lifespan of any industrial equipment, the robust design and meticulous material selection inherent in modern Evaporative Condenser units contribute to significantly lower overall maintenance needs compared to more complex or less robust cooling solutions. Features such as easily accessible internal components, clog-resistant and highly efficient spray nozzles, and durable, low-maintenance fan systems are integrated to minimize potential downtime and reduce the frequency of operational interventions. This design philosophy leads to a lower total cost of ownership (TCO) over the unit's operational lifespan, providing considerable economic benefits to facility operators.

Choosing Your Partner: Manufacturer Comparison and Custom Solutions

Selecting the right supplier for your Evaporative Condenser is as crucial as understanding the technology itself. A reliable manufacturer offers not just a product, but a partnership, providing expertise, quality assurance, and tailored solutions. Longxuan FRP stands out through a combination of extensive experience, continuous innovation, and a deeply customer-centric approach.

What to Look for in an Evaporative Condenser Manufacturer:

- Proven Track Record & Experience: Prioritize manufacturers with extensive and demonstrable experience in the field, evidenced by a history of successful installations and long-term client relationships. Longxuan FRP has been a recognized leader in industrial cooling solutions for several decades, consistently serving diverse industries globally.

- Quality Certifications: Adherence to rigorous international quality standards such as ISO 9001 unequivocally demonstrates a manufacturer's unwavering commitment to consistent product quality and stringent process control. Other relevant certifications like CE marking (for European market compliance) and ASME compliance (for pressure-containing components) are also strong indicators of product safety, reliability, and superior performance.

- Technological Innovation: A truly forward-thinking manufacturer actively invests in research and development (R&D) to continuously improve efficiency, minimize environmental impact, and offer advanced features like smart controls, remote monitoring capabilities, and innovative hybrid designs.

- Material Excellence: Meticulously scrutinize the materials employed for the coils, casing, and all internal components. The use of superior materials, such as hot-dip galvanized steel, premium 304/316L stainless steel, and high-grade Fiber Reinforced Polymer (FRP), is a definitive indicator of a product engineered for exceptional longevity and superior corrosion resistance, crucial for demanding industrial environments.

- Customization Capabilities: Acknowledging that every industrial application possesses unique requirements, a reputable manufacturer should possess the robust capability to offer bespoke solutions. This includes the ability to adapt design, capacity, and material specifications to perfectly match your precise operational needs and site constraints.

- After-Sales Support & Service: Comprehensive technical support, readily available spare parts, and dedicated maintenance services are absolutely crucial for ensuring the long-term reliability and optimal performance of your significant investment. A strong after-sales commitment reflects a manufacturer's confidence in their product and dedication to client success.

- Environmental Responsibility: Partnering with manufacturers who demonstrate a genuine commitment to sustainable practices, offering products compatible with low Global Warming Potential (GWP) refrigerants and incorporating advanced water-saving technologies, aligns perfectly with modern corporate environmental values and regulatory trends.

The Power of Custom-Engineered Solutions

At Longxuan FRP, we deeply understand that a generalized, one-size-fits-all approach is inherently insufficient for addressing the complex and often unique challenges presented by industrial cooling demands. Our distinctive strength lies in our unparalleled ability to provide custom-engineered Evaporative Condenser solutions. This comprehensive customization process involves:

- Site-Specific Analysis: A detailed evaluation of your facility's physical layout, existing infrastructure, specific ambient conditions (critically including wet-bulb temperature and dry-bulb temperature data), and available utility connections. This ensures the design is perfectly integrated into your environment.

- Capacity Matching: Precisely sizing the Evaporative Condenser to your exact heat rejection requirements. This meticulous matching ensures optimal performance and maximum energy efficiency, preventing both costly over-sizing and inefficient under-sizing.

- Material Adaptation: Recommending and utilizing specific materials or grades (e.g., higher grade stainless steel for extremely corrosive environments, specialized protective coatings) to significantly enhance the unit's longevity and performance in particularly challenging applications.

- Integration with Existing Systems: Designing units that seamlessly integrate with your current refrigeration, HVAC, or process cooling loops. This minimizes installation disruption, streamlines commissioning, and maximizes the overall system efficiency.

- Noise & Vibration Control: Implementing specific design features or recommending specialized accessories (e.g., advanced sound attenuators, anti-vibration mounts) for installations where noise reduction is a critical requirement or regulatory mandate.

- Control System Integration: Offering and configuring advanced control options, including robust PLC-based (Programmable Logic Controller) systems and seamless integration with existing building management systems (BMS), for sophisticated intelligent operation, remote monitoring, and comprehensive data logging.

Our collaborative and client-focused approach ensures that the final Evaporative Condenser solution delivered is not merely a product, but a strategically engineered asset meticulously optimized for your long-term operational success, efficiency, and sustainability goals.

Real-World Impact: Evaporative Condenser Application Cases & Client Trust

The true measure of an Evaporative Condenser's value lies in its proven performance in diverse industrial settings under real-world conditions. Longxuan FRP has a proud and extensive history of successful deployments across various sectors, consistently delivering reliable, highly efficient, and durable cooling solutions that directly contribute to our clients' operational goals, energy efficiency targets, and broader sustainability initiatives. Our success is built on the trust and satisfaction of our global clientele.

Client Success Stories and Testimonials (Simulated for illustrative purposes)

-

Large-Scale Petrochemical Complex (Middle East)

Challenge: A prominent petrochemical producer operating in a high-ambient temperature region needed to significantly upgrade their existing ammonia refrigeration system. The primary objectives were to drastically improve energy efficiency, reduce operational costs, and minimize their environmental footprint in line with new regulatory standards.

Solution: Longxuan FRP engineered and supplied multiple custom-designed, high-capacity Evaporative Condenser units. These units featured advanced stainless steel coils for superior corrosion resistance against ammonia and FRP casing for enhanced durability in the arid climate. Our dedicated team provided comprehensive on-site installation support, meticulous commissioning services, and initial operational training.

Result: The implementation of the new system resulted in an impressive 15% reduction in overall refrigeration power consumption. Furthermore, due to optimized drift elimination and intelligent blowdown controls, water makeup requirements were significantly reduced. The client provided glowing feedback, highlighting the units' robust performance, consistent cooling, and remarkably minimal maintenance demands during their first year of intensive operation.

-

Food Processing Plant (Southeast Asia)

Challenge: A large poultry processing facility was grappling with escalating energy costs for its high-demand blast freezing operations. They urgently required a more reliable, energy-efficient, and robust cooling solution capable of withstanding continuous, heavy-duty use in a humid environment.

Solution: We provided modular Evaporative Condenser units specifically engineered for low noise operation—a critical factor for their urban location—and designed for exceptionally easy maintenance access. The units incorporated enhanced water treatment compatibility features and robust, oversized fan systems to ensure reliable performance during demanding continuous operation cycles.

Result: The plant reported a remarkable 12% decrease in refrigeration-related electricity costs, significantly impacting their bottom line. They also noted improved temperature stability within their cold storage facilities, which directly led to enhanced product quality and a substantial reduction in perishable goods spoilage. The modular design proved instrumental, allowing for rapid installation that minimized production downtime and disruptions.

-

Data Center Expansion (Europe)

Challenge: A rapidly expanding data center in a metropolitan area needed a highly efficient, scalable, and environmentally responsible cooling solution for its newly constructed server halls. Strict requirements for energy consumption (low PUE) and guaranteed uptime were paramount.

Solution: Longxuan FRP supplied advanced, high-efficiency Evaporative Condenser systems that were seamlessly integrated with sophisticated smart controls. These controls enabled precise performance tuning based on fluctuating IT load and ambient conditions. The units were specifically selected for their minimal contribution to Power Usage Effectiveness (PUE) and their exceptionally quiet operation, which was crucial given the data center's proximity to residential areas.

Result: The data center successfully achieved its ambitious target PUE, demonstrating outstanding energy efficiency in its cooling infrastructure. The unparalleled reliability of the Evaporative Condenser units played a pivotal role in maintaining the data center's critical 99.999% uptime, ensuring the continuous and uninterrupted operation of vital IT infrastructure and safeguarding invaluable data.

Commitment to Trust and Support: FAQ, Warranty, and Delivery

At Longxuan FRP, building profound trust and fostering long-term relationships with our clients is paramount to our philosophy. This unwavering commitment extends far beyond merely providing high-quality Evaporative Condenser units; it encompasses offering comprehensive and responsive support throughout the entire product lifecycle. Our dedication to transparency, customer satisfaction, and reliable service is vividly reflected in our robust support mechanisms, ensuring peace of mind for every client.

Frequently Asked Questions (FAQ) about Evaporative Condenser

What is the primary difference between an Evaporative Condenser and a Cooling Tower?

The fundamental distinction lies in their function. An Evaporative Condenser directly condenses the hot refrigerant vapor inside its enclosed coils, rejecting heat to the atmosphere through the evaporative cooling of spray water that wets these coils. In contrast, a cooling tower's sole purpose is to cool recirculating process water, which then typically flows through a separate heat exchanger (like a shell-and-tube condenser) to condense the refrigerant. Essentially, the Evaporative Condenser intelligently combines both the heat exchange and evaporative cooling functions into a single, highly efficient unit, resulting in lower condensing temperatures for the entire refrigeration system.

What are the typical materials used in an Evaporative Condenser's construction?

The choice of materials is critical for durability and performance. Common robust materials include hot-dip galvanized steel for the main casing and structural framework (meeting stringent ASTM A123/A153 standards), various grades of stainless steel (typically 304 or 316L) used for the heat exchange coils, water basin, and other critical components exposed to water or corrosive refrigerants. Additionally, Fiber Reinforced Polymer (FRP) is increasingly utilized for casing, fan stacks, and water basins, particularly in highly corrosive environments due to its exceptional chemical resistance and light weight. Coil materials are meticulously selected based on the specific refrigerant type and anticipated operating pressure, with seamless steel (galvanized) and stainless steel being primary, high-performance choices.

How is the lifespan of an Evaporative Condenser determined, and how can it be maximized?

The operational lifespan of an Evaporative Condenser typically ranges from 15 to 25 years. This longevity is primarily determined by three critical factors: the inherent quality of the materials used in its construction, the precision and integrity of the manufacturing processes, and most crucially, the regularity and quality of ongoing maintenance. To maximize the lifespan, consistent and effective water treatment is absolutely essential to prevent scaling, biological fouling, and corrosion. Routine inspection of all key components (such as fans, pumps, spray nozzles, and drift eliminators), prompt replacement of any worn or damaged parts, and strict adherence to the manufacturer's recommended preventive maintenance schedules are vital. The initial investment in units made with robust materials like hot-dip galvanized steel and stainless steel also significantly contributes to long-term durability.

What inspection standards do your Evaporative Condenser units comply with?

Our Evaporative Condenser units are designed, manufactured, and rigorously tested in strict accordance with a suite of international quality and performance standards. This includes ISO 9001 for our comprehensive quality management systems, ensuring consistent production excellence. We also comply with CE marking requirements for products destined for the European market, signifying conformity with health, safety, and environmental protection standards. Furthermore, our units adhere to CTI (Cooling Technology Institute) standards for certified thermal performance ratings, guaranteeing their stated cooling capacities. Specific pressure-containing components like coils may also meet ASME (American Society of Mechanical Engineers) codes, and other components may conform to relevant ANSI (American National Standards Institute) standards, ensuring overall product integrity and safety.

Can an Evaporative Condenser operate effectively in varying climate conditions?

Yes, Evaporative Condensers are engineered for highly effective and reliable operation across a broad spectrum of ambient climatic conditions, from arid to humid, and hot to cold. Their inherent efficiency is directly linked to the ambient wet-bulb temperature, which means they perform exceptionally well even in humid climates. For installations in colder regions or during winter months, specific features are integrated to ensure continuous and safe operation. These may include electric basin heaters to prevent water freezing in the sump, intelligent control systems that manage fan speed and water flow to prevent icing, and specific winterization kits. This adaptability makes them a versatile solution globally.

What is the typical delivery period for an Evaporative Condenser?

The typical delivery period for an Evaporative Condenser varies based on several factors, including the specific model selected, the degree of customization required for your application, and our current production schedule. For standard models, clients can generally expect a lead time of approximately 6-10 weeks from the confirmed order date. However, for highly custom-engineered solutions or exceptionally large-scale projects, the lead time may extend to 12-20 weeks to accommodate specialized design, material procurement, and manufacturing processes. We are committed to transparency and provide a detailed, accurate project timeline upon order confirmation, maintaining clear communication throughout the manufacturing and logistics phases to keep you informed.

What kind of warranty and after-sales support do you offer?

Longxuan FRP is dedicated to the quality and longevity of our products. We typically offer a comprehensive warranty of 18 months from the date of shipment or 12 months from the date of commissioning (whichever occurs first) on all our Evaporative Condenser units. This warranty covers manufacturing defects and ensures the integrity of our craftsmanship. Beyond the warranty period, our commitment to our clients continues with robust, long-term after-sales support. This includes readily available spare parts supply, expert technical troubleshooting, convenient remote assistance, and optional on-site maintenance services provided globally. Our dedicated customer support team is always available and eager to assist with any operational queries, technical challenges, or service requirements you may have, ensuring your investment continues to perform optimally.

Optimize Your Operations with a Leading Evaporative Condenser Solution!

Ready to significantly enhance your industrial cooling efficiency, reduce operational costs, and improve your environmental footprint? Our team of highly skilled experts is dedicated to providing a tailored Evaporative Condenser solution that perfectly aligns with your specific operational needs and long-term strategic goals. Don't let outdated cooling methods hinder your progress. Contact us today for a personalized consultation or to request a detailed, no-obligation quote. Let us help you achieve superior cooling performance.

Get a Quote Now!Further Reading & Industry Insights

- "Fundamentals of Evaporative Cooling" - Cooling Technology Institute (CTI). A foundational document on the principles and applications of evaporative cooling systems, including their role in industrial refrigeration. https://www.cti.org/pubs/CTI_J-1.pdf

- "Energy Efficiency of Industrial Refrigeration Systems" - U.S. Department of Energy. This comprehensive guide details strategies and technologies, including evaporative condensers, for optimizing energy consumption in industrial refrigeration. https://www.energy.gov/sites/prod/files/2013/11/f5/refrigeration_guide_0.pdf

- "Advances in Evaporative Cooling Technology for Data Centers" - ASHRAE Journal. An academic publication exploring cutting-edge evaporative cooling methods and their efficiency gains in high-density data center environments. (Requires subscription for full access to articles). https://www.ashrae.org/technical-resources/ashrae-journal

- "Materials Selection for Cooling Towers and Condensers in Industrial Applications" - NACE International. This peer-reviewed content (often requires subscription) provides in-depth analysis on corrosion prevention and material durability in challenging industrial cooling systems. https://www.nace.org/

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China