Introduction to Evaporative Condenser

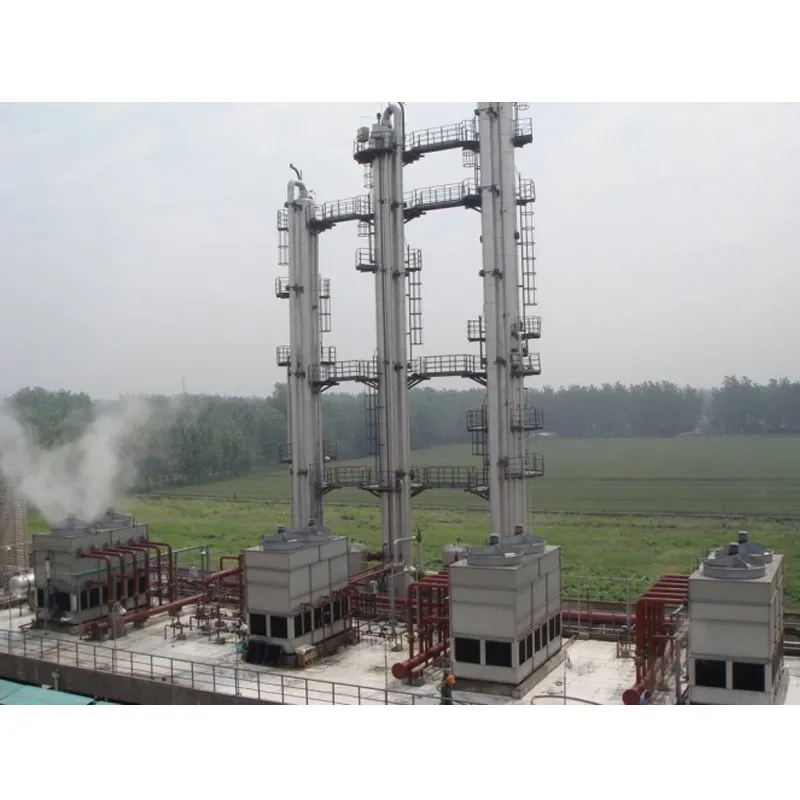

In the dynamic and energy-intensive environments of modern industry, achieving efficient heat dissipation is paramount. Evaporative Condenser technology has emerged as a leading solution, blending process innovation with high performance and eco-friendly design. With a broad range of applications from casting, forging to air conditioning, heat pumps, and process engineering, these condensers represent a key link in the thermal management chain.

Hebei Longxuan Environmental Protection Equipment Co., LTD. is recognized as a benchmark enterprise in this sector, supplying top-quality Evaporative Condenser systems tailored to diverse industrial requirements worldwide.

Industry Trends & Market Outlook

The global demand for Evaporative Condenser solutions is projected to grow steadily due to rapid industrialization, urban infrastructure expansion, and higher standards for energy efficiency and sustainability. According to industry research, energy consumption reduction and compact system design are primary motivating factors across sectors such as food & beverage, HVAC, power plants, and petrochemical industries.

- Eco-Efficiency: Increasing pressure for environmental compliance is accelerating the adoption of closed-circuit and low-drift evaporative technology.

- Smart Control Integration: Digitally managed evaporative systems optimize water usage and heat rejection under varying climatic conditions.

- Material Innovations: Advanced anti-corrosion coatings, stainless steel, and FRP housing enhance Evaporative Condenser lifespan.

Technical Parameters of Evaporative Condenser

| Parameter | Specification | Industry Reference |

|---|---|---|

| Cooling Capacity | 25-5000 T/h (single room unit) | Product Page |

| Application Areas | Casting, Forging, Air Compressor, Central Air Conditioning, Ground Source Heat Pump, Printing Machine, Die Casting Machine, Injection Molding Machine | Industry Article |

| Cooling Medium | Pure Water | ASHRAE Journal [ref] |

| Heat Transfer Coefficient | Up to 3500 W/m²·K | ScienceDirect |

| Material | FRP, Stainless Steel, Galvanized Steel | CTI Technical Paper [ref] |

| Power Consumption | 6-9 kW per 1000 T/h | ScienceDirect |

| Water Consumption | 0.03-0.07 m³/h per ton | ASHRAE Handbook [ref] |

| Noise Level | <58 dB(A) | Environmental Compliance |

Application Scenarios for Evaporative Condenser

Evaporative Condenser units are at the heart of multiple industries for their superior heat rejection, reduced footprint, and reliability. The following scenarios represent major application fields:

- HVAC Systems: Ensures energy-efficient central cooling for commercial buildings and complexes.

- Steel and Metal Casting: Provides precise cooling crucial for forging and die casting machinery.

- Plastics & Chemical Processing: Maintains optimal temperature for injection molding and extruder lines.

- Food & Beverage Industry: Offers dependable process cooling for continuous production environments.

- Power Generation: Facilitates condenser heat extraction for turbines and compressors.

- Ground Source Heat Pumps: Enhances energy recovery in advanced HVAC systems.

Product Spotlight: Evaporative Condenser from Hebei Longxuan

Cooling Capacity: 25-5000 T/h (single room units)

Applicable Fields: Casting, forging, air compressor systems, HVAC, ground source heat pumps, printing and die casting machines, injection molding.

Cooling Medium: Pure water

Full product details: Evaporative Condenser

Frequently Asked Technical Questions about Evaporative Condenser

- 1. What materials are most commonly used for Evaporative Condenser construction?

- A: Premium-grade FRP (Fiber Reinforced Plastic), stainless steel, and hot-dipped galvanized steel are leading choices, offering excellent resistance to corrosion, thermal fatigue, and chemical exposure.

- 2. What specifications should be considered when selecting an Evaporative Condenser?

- A: Core specs include cooling capacity (T/h), heat transfer coefficient, water consumption rate, footprint, power consumption, and material compatibility based on operating environment.

- 3. Are there recognized installation standards for Evaporative Condensers?

- A: Yes. Installations should comply with ASHRAE guidelines (see ASHRAE Installation Standards) ensuring optimal airflow, isolation from pollutant sources, and easy access for inspection and maintenance.

- 4. How is energy efficiency calculated for an Evaporative Condenser?

- A: By evaluating heat rejection capacity per unit of electrical and water consumption, and considering seasonal performance coefficients (COPs), especially in comparison with air-cooled condensers.

- 5. Which technical parameters have the highest impact on operational cost?

- A: Water makeup, power usage, periodic cleaning frequency, and fan/motor reliability are key. Choosing high-efficiency fans and drift eliminators minimizes operational expenses.

- 6. Can Evaporative Condenser units be adapted for extreme climates?

- A: Yes, with adaptations like reinforced housing, corrosion-resistant coatings, anti-icing packages, and smart climate control integration, their operation is stable even in temperature extremes or corrosive environments.

- 7. What are typical maintenance requirements?

- A: Routine maintenance involves basin cleaning, nozzle unclogging, drift eliminator checks, and inspection of fans/motors. Using pure water as cooling medium reduces scaling and extends service life.

Professional FAQ Section

Authority, Credibility & Industry References

Evaporative Condenser systems, as implemented by Hebei Longxuan Environmental Protection Equipment Co., LTD., are backed by technical standards from global organizations such as Cooling Technology Institute (CTI) and ASHRAE. All equipment adheres to strict QC and energy-efficiency criteria, with reference to peer-reviewed publications and best practice recommendations in the cooling industry.

- Cooling Technology Institute (CTI): https://www.cti.org/

- ASHRAE Technical Resources: ASHRAE.org

- “Evaporative Condensers Enhance Energy Savings” in Cooling Best Practices: coolingbestpractices.com

- ScienceDirect – Evaporative Condenser Review: sciencedirect.com

- ASHRAE Journal, Peer-Reviewed Articles: ashrae.org