We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Driving Efficiency and Sustainability: The Role of Advanced Cooling Towers

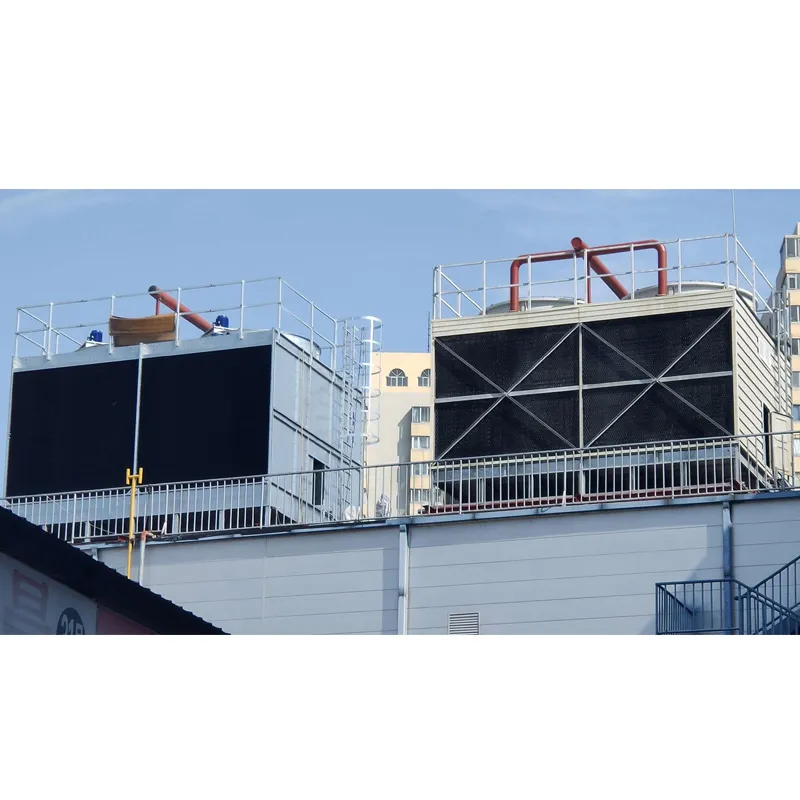

In the intricate world of modern HVAC and industrial process cooling, the air conditioning cooling tower stands as a cornerstone of operational efficiency and environmental responsibility. These sophisticated systems are pivotal for rejecting waste heat from chillers, condensers, and various industrial equipment, ensuring stable operating temperatures and optimizing energy consumption. As industries globally grapple with escalating energy costs and stringent environmental regulations, the demand for high-performance, durable, and energy-efficient cooling solutions has never been more critical. This comprehensive guide delves into the essential aspects of air conditioning cooling towers, covering their technological advancements, strategic applications, and the inherent advantages they offer to B2B stakeholders. We explore the design principles, material science, and manufacturing excellence that define leading-edge cooling tower systems, empowering businesses to make informed decisions for their infrastructure needs.

Industry Trends and Market Dynamics in Cooling Technology

The global market for cooling towers is experiencing robust growth, driven primarily by increased industrialization, commercial infrastructure expansion, and a burgeoning focus on sustainable operations. A significant trend shaping this market is the shift towards highly efficient and environmentally friendly cooling solutions, with an emphasis on reduced water consumption and lower energy footprints. Innovations in materials, such as advanced Fiber-Reinforced Polymer (FRP) composites and specialized corrosion-resistant alloys, are enhancing the longevity and performance of these systems. Furthermore, the integration of smart technologies, including IoT sensors, predictive maintenance algorithms, and AI-driven control systems, is transforming traditional air conditioning cooling tower operations into intelligent, self-optimizing units. These advancements not only improve operational reliability but also provide real-time data for optimizing energy use and minimizing downtime, aligning with the industry's push for greater operational transparency and efficiency.

Regulatory frameworks worldwide, such as the EPA's guidelines for water usage and emissions, are compelling industries to adopt more sustainable cooling practices. This has led to a surge in demand for closed-circuit cooling towers and hybrid systems that offer superior water conservation capabilities. Manufacturers are also focusing on modular designs, which facilitate easier installation, maintenance, and scalability for diverse industrial and commercial applications. The push for improved power usage effectiveness (PUE) in data centers, for instance, has significantly boosted the adoption of optimized cooling tower ac units that deliver precise temperature control with minimal energy expenditure. This dynamic market environment necessitates suppliers who can provide not just products, but holistic cooling solutions tailored to specific operational demands and environmental targets.

Core Functionality and Key Technical Parameters

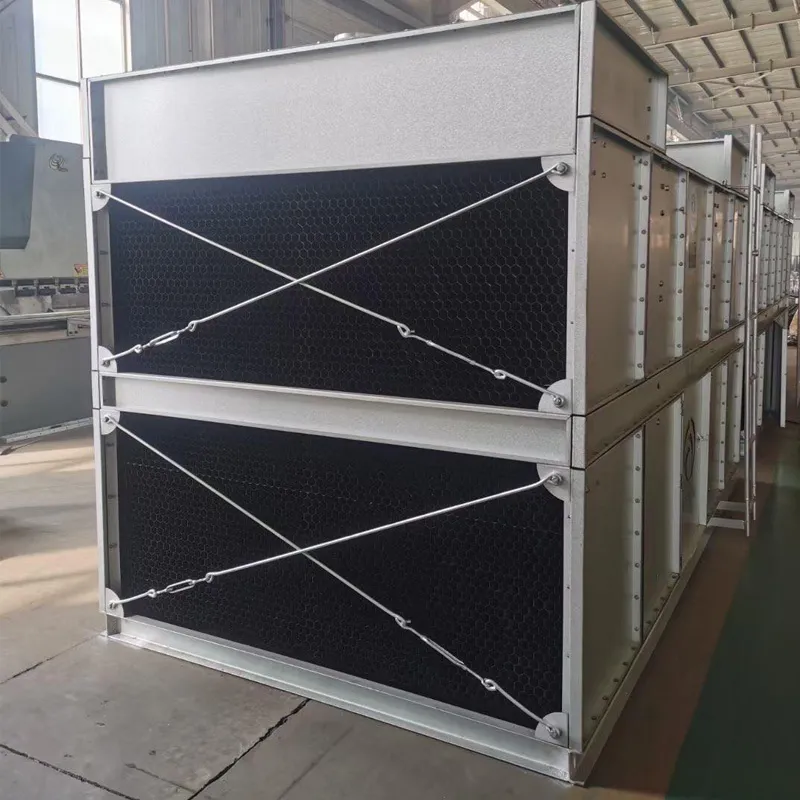

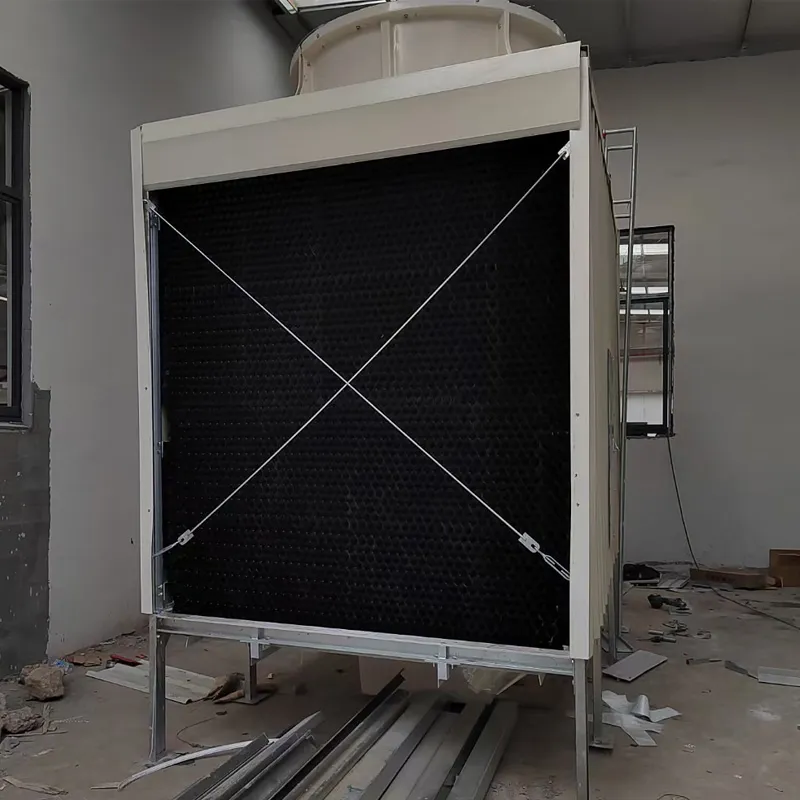

At its core, a cooling tower in air conditioning system functions on the principle of evaporative cooling, where a small portion of the circulating water evaporates into the atmosphere, dissipating latent heat from the remaining water. This process cools the water, which is then recirculated to absorb more heat from the conditioned space or industrial process. Key components include the casing, fill media (which maximizes surface area for evaporation), spray nozzles (for even water distribution), a fan (for air movement), and a drift eliminator (to minimize water loss). The efficiency of this heat exchange is quantified by several critical technical parameters that dictate a cooling tower’s suitability for a given application.

Understanding these parameters is crucial for optimal system design and operation. For instance, the cooling capacity, often measured in tons of refrigeration or BTU/hr, determines the amount of heat the tower can reject. The flow rate indicates the volume of water the tower can process, while the approach temperature (the difference between the cooled water temperature and the wet-bulb temperature of the ambient air) is a direct measure of efficiency. Noise levels, particularly important for urban installations, are also a significant consideration. Materials of construction, critical for longevity and corrosion resistance, vary from galvanized steel to stainless steel and advanced FRP composites, each offering distinct advantages depending on the operational environment and water chemistry.

Typical Air Conditioning Cooling Tower Parameters

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Cooling Capacity | Heat rejection capability | 5 TR to 2000+ TR (Tons of Refrigeration) |

| Water Flow Rate | Volume of water circulated | 20 GPM to 10,000+ GPM |

| Inlet Water Temp. | Temperature of water entering tower | 35°C to 50°C (95°F to 122°F) |

| Outlet Water Temp. | Temperature of water leaving tower | 28°C to 35°C (82°F to 95°F) |

| Approach Temperature | Outlet water temp. - Wet-bulb temp. | 3°C to 7°C (5°F to 12°F) |

| Materials of Construction | Main components and casing | FRP, Galvanized Steel, Stainless Steel |

| Noise Level | Sound pressure level at specified distance | 60 dB to 85 dB (at 1m) |

| Design Life | Expected operational lifespan | 15-25+ years |

The design of a cooling tower in refrigeration system is fundamentally influenced by the specific refrigeration load, ambient wet-bulb temperature, and desired approach and range. Range refers to the difference between the hot water inlet temperature and the cold water outlet temperature, indicating the temperature drop achieved. High efficiency fill media, such as PVC film fill or splash fill, are engineered to maximize the air-water contact surface area, thereby enhancing the heat transfer coefficient and improving overall cooling performance. Selecting the right fan type—axial or centrifugal—is also critical, influencing both energy consumption and noise output. Axial fans are common for large-volume air movement with lower static pressure, while centrifugal fans are preferred for higher static pressure applications and quieter operation.

Manufacturing Process and Quality Assurance

The manufacturing of a robust air conditioning cooling tower is a testament to precision engineering and stringent quality control. The process typically begins with the selection of high-grade raw materials. For FRP cooling towers, this involves industrial-grade resin systems and fiberglass mats, chosen for their superior corrosion resistance, high strength-to-weight ratio, and UV stability. Steel components, if used, undergo meticulous hot-dip galvanization or are fabricated from stainless steel (e.g., SS304 or SS316) to ensure long-term durability in corrosive environments.

Key manufacturing steps include precision molding for FRP components, where advanced techniques ensure uniform thickness and structural integrity. Metal parts undergo CNC machining for accurate dimensions, followed by welding and surface treatments. Assembly is carried out under strict quality protocols, ensuring that components fit seamlessly and perform as designed. Each critical component, such as the fan assembly, motor, and water distribution system, is rigorously tested prior to final integration. Comprehensive inspection standards, including adherence to ISO 9001 for quality management and ANSI/CTI (Cooling Technology Institute) standards for performance rating, are applied throughout the production cycle. This multi-layered quality assurance process guarantees that the finished ac cooling tower system meets or exceeds specified performance criteria, boasts a reliable service life often exceeding 20 years, and can withstand the demanding conditions of various industrial applications.

Key Technical Advantages: Beyond Basic Cooling

Modern air conditioning cooling tower systems offer a myriad of technical advantages that translate directly into operational savings and improved sustainability. Foremost among these is energy efficiency. By efficiently dissipating heat, these towers enable chillers and other heat-generating equipment to operate at lower condensing temperatures, significantly reducing power consumption. For every degree Celsius reduction in condensing temperature, chiller efficiency can improve by 2-4%, leading to substantial energy cost savings over the system's lifespan. This directly contributes to a lower Power Usage Effectiveness (PUE) in data centers and reduced carbon footprints for industrial facilities.

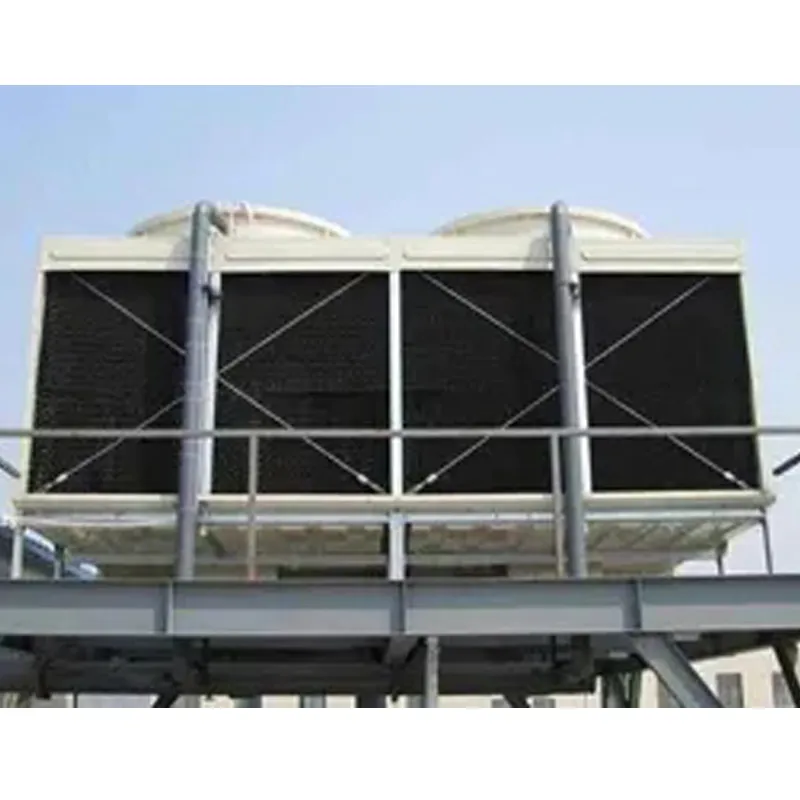

Another critical advantage is superior corrosion resistance, especially with models constructed from advanced FRP or stainless steel. Unlike traditional galvanized steel towers, which are susceptible to corrosion and require frequent maintenance, modern materials extend the service life and reduce the need for costly repairs. Water conservation is also a significant benefit; while evaporative cooling consumes water, advanced drift eliminators and sophisticated control systems minimize water loss, making them more water-efficient than once-through cooling systems. Furthermore, low noise operation, achieved through optimized fan designs and acoustic dampening materials, makes these towers suitable for noise-sensitive environments like hospitals and residential areas. Their modular design also simplifies installation and future expansion, providing flexibility for evolving operational demands.

Versatile Application Scenarios Across Industries

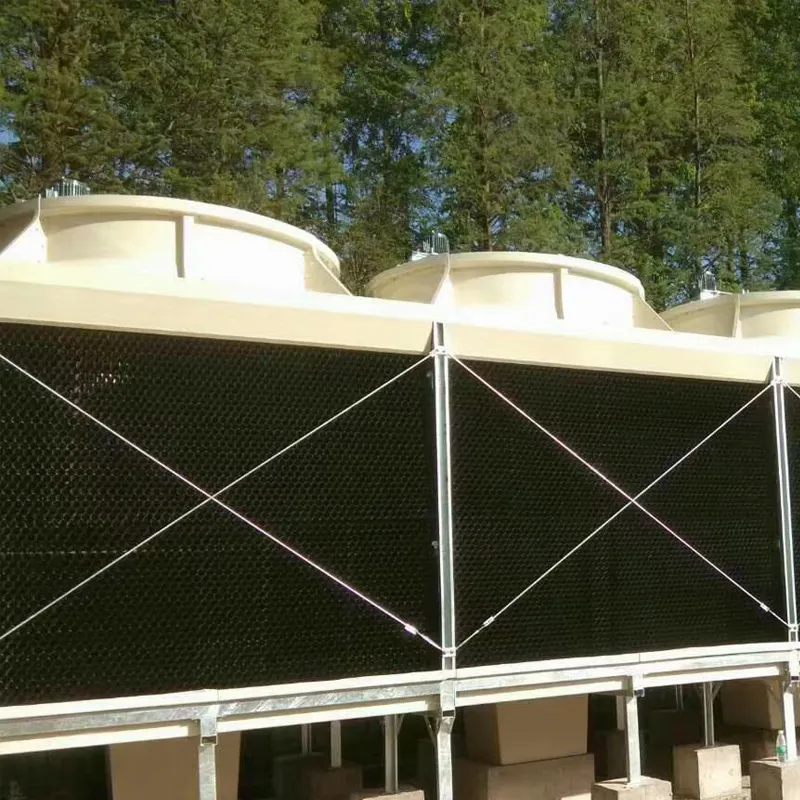

The adaptability of air conditioning cooling tower systems makes them indispensable across a diverse range of industries. In commercial HVAC, they are the backbone of comfort cooling in large office buildings, shopping malls, airports, and universities, efficiently managing heat loads from centralized air conditioning systems. Data centers, which require precise temperature and humidity control for optimal server performance, heavily rely on these towers to maintain stable environments, contributing directly to their PUE metrics. Hospitals and healthcare facilities utilize cooling towers for their HVAC systems, ensuring comfortable and sterile conditions, and for specialized medical equipment cooling.

Industrially, the application spectrum is even broader. In the petrochemical sector, cooling tower ac units are vital for cooling process fluids, reaction vessels, and compressors. Metallurgy and power generation plants use them to cool turbines, condensers, and other heavy machinery, playing a crucial role in maintaining operational stability and efficiency. The chemical industry, food and beverage processing, and pharmaceutical manufacturing also depend on these towers for precise temperature control in their production lines and facility cooling. For instance, in food processing, reliable cooling ensures product quality and safety by preventing spoilage. In the water supply and drainage sector, these towers are integral to large-scale water treatment and circulation systems, highlighting their robustness and critical role in diverse heavy industries.

Customized Solutions and Engineering Expertise

Recognizing that no two cooling requirements are identical, a leading provider of air conditioning cooling tower solutions offers extensive customization capabilities. This begins with a thorough site assessment, where experienced engineers analyze factors such as available space, environmental conditions (e.g., wet-bulb temperature, prevailing winds), heat load requirements, and desired energy efficiency targets. Based on this assessment, bespoke designs are developed, integrating specific materials, fan configurations, and control systems to optimize performance for the unique application.

The engineering team leverages advanced simulation software and decades of field experience to predict performance accurately and ensure optimal system integration. For example, a petrochemical plant might require a highly robust, explosion-proof cooling tower ac units with specialized fill media to handle aggressive water chemistry, while a hospital might prioritize ultra-low noise and minimal drift. This consultative approach extends to post-installation support, including commissioning, training for facility staff, and ongoing maintenance programs. Such end-to-end expertise ensures that the cooling solution not only meets immediate needs but also provides long-term reliability and operational cost advantages.

Application Case Studies and Customer Success

Our commitment to engineering excellence and client satisfaction is best illustrated through real-world applications. Consider a recent project for a major data center in a hot, humid climate. The client required an air conditioning cooling tower system capable of maintaining a constant water temperature of 29°C for their chillers, even with ambient wet-bulb temperatures reaching 27°C, while also minimizing water consumption and noise. Our team designed and implemented a series of counter-flow FRP cooling towers featuring high-efficiency PVC film fill and low-noise axial fans. The result was a 15% reduction in annual energy consumption compared to their previous system and a noise level consistently below 65 dB at 1 meter, well within the client's strict requirements. This contributed directly to a PUE of 1.3, showcasing significant operational cost savings and environmental benefits.

Another compelling case involves a large-scale chemical processing plant that needed to replace aging, corrosion-prone steel cooling towers. The highly corrosive process water and chemical fumes had severely degraded their existing infrastructure. We proposed a bespoke cooling tower in air conditioning system solution constructed almost entirely from composite FRP materials, including the structural frame, casing, and fan stack. This design, combined with chemical-resistant PVC fill and drift eliminators, ensured unparalleled resistance to corrosive media. Post-installation, the client reported a dramatic decrease in maintenance frequency and costs, and an increase in overall plant uptime. This project highlighted the long-term reliability and low lifecycle cost benefits of selecting application-appropriate materials and expert design for challenging industrial environments. Our extensive service history, spanning over two decades, underscores our proven track record in delivering robust and reliable cooling solutions for critical applications worldwide.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of an air conditioning cooling tower?

A1: With proper design, quality materials (like FRP or stainless steel), and regular maintenance, our cooling towers are designed for a service life of 15-25 years or more. Factors like water quality, environmental conditions, and maintenance frequency significantly influence longevity. Our FRP models are particularly known for their extended durability in challenging environments.

Q2: How do your cooling tower ac units contribute to energy savings?

A2: Our cooling towers are engineered with high-efficiency fill media, optimized fan designs, and advanced water distribution systems to maximize heat rejection. By maintaining lower condenser water temperatures, they allow chillers and other refrigeration equipment to operate more efficiently, reducing their power consumption and contributing directly to lower operational costs and improved PUE.

Q3: What maintenance is required for a cooling tower in air conditioning system?

A3: Regular maintenance includes routine inspections, cleaning of fill media and basin to prevent scaling and biological growth, checking water treatment programs, lubricating fan bearings, and inspecting electrical components. Our systems are designed for ease of maintenance, with accessible components and robust materials that reduce the frequency of major overhauls. We also offer comprehensive maintenance plans.

Q4: Can your cooling towers be customized for specific industrial applications?

A4: Absolutely. We specialize in providing customized cooling solutions. Our engineering team works closely with clients to understand their unique heat load, space constraints, environmental conditions, and water quality requirements. We can tailor materials, fan types, capacity, and control systems to deliver an optimal cooling tower in refrigeration system that perfectly fits the application, whether it's for petrochemical, power generation, or specialized manufacturing processes.

Delivery and Customer Support Commitment

We understand the critical importance of timely delivery and unwavering support in B2B projects. Our typical lead times for standard ac cooling tower system models range from 4-8 weeks, depending on customization and order volume, with expedited options available for urgent requirements. Each unit undergoes rigorous pre-shipment inspection to ensure it arrives in perfect condition. Our global logistics network ensures efficient and secure delivery to project sites worldwide.

Beyond delivery, our commitment extends to comprehensive after-sales support. We offer detailed installation guidance, on-site supervision for complex projects, and extensive training for your operational and maintenance teams. Our products are backed by a robust warranty ranging from 1 to 5 years on various components, reflecting our confidence in their quality and durability. Furthermore, our dedicated technical support team is available 24/7 to address any operational queries or troubleshooting needs, ensuring minimal downtime and continuous peak performance of your air conditioning cooling tower system. We prioritize long-term partnerships, providing peace of mind through reliable products and unparalleled service.

Conclusion: The Future of Efficient Cooling

The evolution of the air conditioning cooling tower is a testament to the ongoing pursuit of efficiency, sustainability, and reliability in industrial and commercial cooling. As global energy demands rise and environmental stewardship becomes paramount, advanced cooling tower systems are not merely components but strategic investments that yield significant operational savings and align with corporate sustainability goals. By integrating cutting-edge materials, smart technologies, and precision engineering, modern cooling towers deliver unmatched performance, durability, and a lower total cost of ownership. Choosing a reputable manufacturer with a proven track record, extensive customization capabilities, and robust after-sales support is crucial for unlocking the full potential of these essential systems. Invest in a cooling solution that empowers your operations, reduces your environmental impact, and provides long-term value.

References:

- Cooling Technology Institute (CTI) - Performance Guidelines for Industrial Water Cooling Towers.

- ASHRAE Handbook - HVAC Systems and Equipment (Chapter on Cooling Towers).

- U.S. Department of Energy - Energy Efficiency and Renewable Energy, Cooling Tower Best Practices.

- Journal of Heat Transfer - Research on Evaporative Cooling and Heat Exchanger Performance.

- International Organization for Standardization (ISO) - ISO 9001: Quality Management Systems.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China