We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

As energy efficiency and process safety become pillars in modern industry, the Air Conditioning Cooling Tower plays a decisive role in HVAC, petrochemical, metallurgy, and water treatment sectors worldwide. This comprehensive guide explores the evolution, technical excellence, manufacturing flow, case studies, and the competitive landscape of cooling towers optimized for air conditioning systems.

1. Industry Trends: Air Conditioning Cooling Tower Market Outlook (2024-2028)

- Global CAGR: The air conditioning cooling tower market is projected to grow at a CAGR of 5.9% between 2024-2028 (MarketsandMarkets).

- Key Drivers: Energy-saving mandates, urbanization, expansion of commercial complexes, and stricter emission norms (ISO 14001, ASHRAE standards).

- Popular Technologies: Closed-circuit FRP towers, variable frequency drives, eco-friendly fill media.

- Application Sectors: Commercial HVAC, oil & gas, metallurgy, pharmaceuticals, and data centers.

Did you know?

According to HPAC Engineering Magazine, over 82% of new commercial buildings in North America now utilize advanced Air Conditioning Cooling Tower systems for central chillers.

2. Technical Specifications: Core Parameters of Air Conditioning Cooling Tower

Modern Air Conditioning Cooling Tower solutions leverage corrosion-resistant FRP (Fiber-Reinforced Plastic), CNC machining for precision components, and epoxy protective coatings for longevity. Typical product features align with ANSI, ISO 9001:2015, and ASHRAE 90.1 standards.

| Parameter | Unit | Value | Standard |

|---|---|---|---|

| Cooling Capacity | RT (Refrigeration Tons) | 100–1500 | ISO 5149 |

| Heat Rejection | kcal/h | 30,000–450,000 | ASHRAE 90.1 |

| Water Flow Rate | m³/h | 20–700 | ANSI B9.1 |

| Inlet/Outlet Water Temp. | °C | 37 / 32 | ISO 11790 |

| Noise Level | dB(A) | ≤62 | GB/T 7190 |

| Material (Casing/Tank) | — | FRP/SS 304/HDG Steel | ISO 9001:2015 |

| Warranty | years | 10+ | Manufacturer |

| Corrosion Resistance | Grade | High | ASTM D543 |

3. Manufacturing Process of Air Conditioning Cooling Tower

Step-by-step Process Diagram:

- Raw Material Selection → Use premium fiberglass (FRP), stainless steel/galvanized steel for structure. Ensures anti-corrosive and high load capacity.

- Shell Molding & Casting → Automated FRP shell casting with precise wall thickness control (ISO 9001).

- CNC Machining → Key parts (fans, shafts, water distribution nozzles) made by 5-axis CNC for tight tolerances and balance.

- Component Assembly → Modular filling, drift eliminators, and drive motor installed according to ANSI B9.1 standards.

- Anti-corrosion Coating → Epoxy/PU coatings on all metal parts to pass ASTM salt spray test.

- Quality Testing → Each unit is performance tested (thermal rejection, noise, vibration) and undergoes hydrostatic leak tests.

- Packing & Dispatch → Export grade packaging and shock-proof crating for global logistics.

Note: Every Air Conditioning Cooling Tower is ISO 9001:2015 certified and comes with detailed inspection documentation.

Highlights of Material & Manufacturing Advantages

- FRP & 304SS Construction: Resists harsh chemicals, 30+ year service life in coastal/industrial environments.

- Energy-efficient Fill Media: Advanced honeycomb PVC/PP structure ensures maximal thermal exchange and minimizes drift loss.

- Noise & Vibration Control: Aerodynamic fans and anti-vibration mountings achieve ≤62 dB(A).

- International Compliance: ISO 5149 (Refrigeration), ISO 14001 (Environmental), ANSI, and CE certified components.

4. Product Comparison: Leading Air Conditioning Cooling Tower Manufacturers (2024)

| Brand | Model | Cooling Capacity (RT) | Material | Noise Level (dB) | Corrosion Resistance | Warranty (years) | Certification |

|---|---|---|---|---|---|---|---|

| LONGXUAN | LX-CTF-FRP1200 | 1200 | FRP+Stainless | 61 | Excellent | 10 | ISO/CE/ANSI |

| SPX Marley | NC8407 | 1000 | FRP/Hot-dip Steel | 65 | Very Good | 5 | ASHRAE/CE |

| Baltimore Aircoil | PT2-1215 | 1150 | SS304 | 63 | Excellent | 7 | ISO/UL/CSA |

| EVAPCO | AT-1100 | 1100 | Hybrid FRP | 64 | Good | 6 | ASHRAE/CE |

Conclusion: Air Conditioning Cooling Tower by LONGXUAN leads on corrosion resistance, low noise, and warranty period.

5. Tailored Solutions for Air Conditioning Cooling Tower Projects

Customized Design Process

- Requirement Analysis: Detailed survey of building/site parameters (heat load, water quality, ambient climate, noise restrictions).

- Engineering Selection: Computer-aided design using HAP/Carrier software for accurate cooling tower sizing.

- Material Optimization: Select optimal FRP thickness, fill media, and drive system for each project.

- On-Site Installation Services: Certified technicians, adherence to OSHA & local building codes, ISO-compliant quality audits.

- After-sales & Monitoring: IoT-based temperature/vibration monitoring, full warranty, and spare parts assurance.

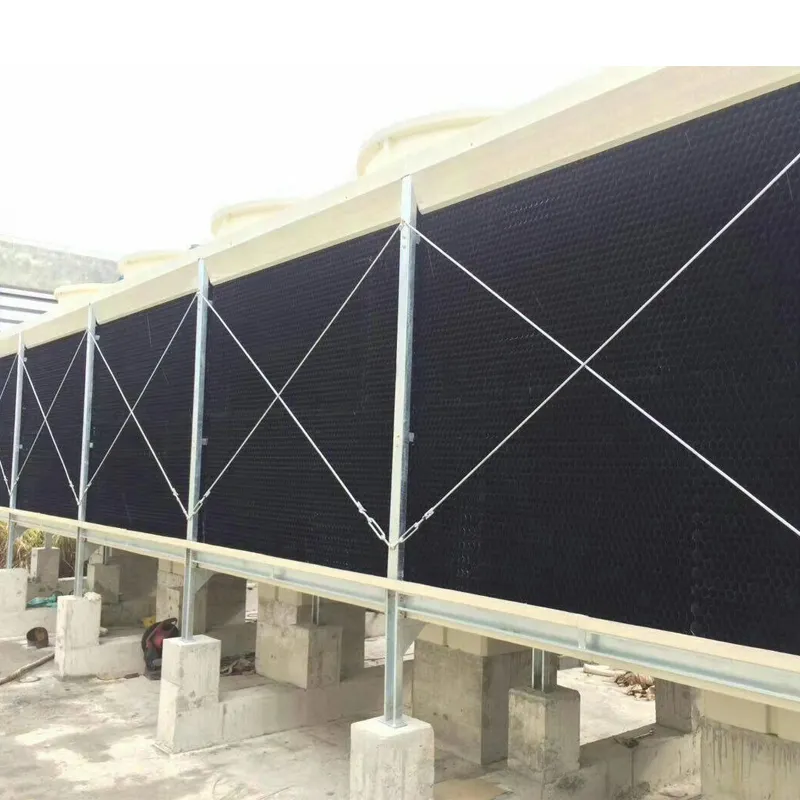

6. Application Case Studies: Air Conditioning Cooling Tower in Practice

Case 1: Central Chiller Plant, Commercial Office Complex (Singapore)

- Project Scope: Retrofit, 5,000 RT total load; replaced 4 old metal towers with LONGXUAN FRP Hybrid units.

- Results: Energy consumption reduced by 12.7%; maintenance cost down 31% after 2 years.

- Key Features Applied: Sound attenuation, anti-scale fill, IoT temp sensors.

- Client Feedback: “Running noise is drastically lower, and no visible corrosion after 30 months – highly recommended.”

Case 2: Chemical Plant Heat Rejection (Middle East)

- Challenges: Harsh saline environment, 42°C day summer highs.

- Solution: Special marine grade FRP, high-pressure static water spray system, acid-proof fill.

- Outcome: Stable operation, zero corrosion, reduced drift loss by 26%.

More Real-World Sectors

- Petrochemical process cooling (refining, reactor cooling)

- Steel and Metallurgy quenching lines

- Pharmaceuticals, Food & Beverage (FDA-grade towers on request)

- Municipal water HVAC and data centers

“To maximize service life and thermal efficiency, Air Conditioning Cooling Tower users should perform quarterly vibration and water analysis. The feedback from our long-term customers shows up to 90% reduction in emergency downtimes.”

— Site Engineer, Global Data Center Operator (2023 client feedback)

7. Data Visualization: Performance & Material Analysis

8. Professional FAQ: Air Conditioning Cooling Tower Technical Glossary

Q1. What is the typical FRP material thickness and why does it matter?

A: Top-grade Air Conditioning Cooling Tower casings use 5–8 mm FRP thickness, ensuring high rigidity and impact resistance, exceeding ASTM D3841 standards. Thicker FRP performs better against UV and industrial pollutants.

Q2. Which certifications should one look for?

A: Look for ISO 9001:2015 for manufacturing, ISO 14001 for environment, ASHRAE 90.1 energy compliance, ASTM-D543 for corrosion, and optionally CE/CSA/UL for electrical safety if needed.

Q3. What is noise level (dB) and its significance?

A: Noise output, measured in dB(A), indicates environmental comfort. Premium towers maintain ≤62 dB(A) to meet building/urban environmental codes.

Q4. How are fans and drives engineered?

A: Use aluminum or composite axial fans, balanced via CNC machining, and direct/speed-reduced gear drives; this assures high airflow and stable long-term performance for the Air Conditioning Cooling Tower.

Q5. Describe installation standards for cooling towers?

A: Follow ANSI/EASA, ISO 5149 & local norms: anti-vibration pads, seismic anchoring, straight runs for pipework, and thorough hydro/leak testing post-install. Always request a commissioning report from your supplier.

Q6. What advantages does corrosion-resistant design offer?

A: FRP/SS304 structure resists industrial chemicals (H2SO4, NaOH), moisture, and salt spray, ensuring 25+ year lifespan without costly recoating.

Q7. How does warranty and service support work?

A: LONGXUAN Air Conditioning Cooling Tower provides a 10-year structural warranty, 24/7 technical support, remote diagnostics (for IoT models), and global spare parts within 7–21 days of request.

9. Delivery, Warranty & Support

- Delivery Cycle: Standard lead time is 15–30 working days depending on customization.

- Warranty Coverage: 10 years for structure, 24 months for drive/electricals, lifetime after-sales technical consultation.

- Onsite Support: Global team covers installation, commissioning, and periodic maintenance.

- Spare Parts Assurance: Original accessories shipped worldwide within 7–21 days.

10. Frequently Asked Questions

- Does the Air Conditioning Cooling Tower comply with international standards?

Yes, fully ISO, ANSI, ASHRAE compliant with certification documents available for audit. - What water quality is required?

Typical make-up water quality: suspended solids ≤20mg/L, TDS ≤2000mg/L. Specialized fill media available for hard/acidic water. - How are towers cleaned and maintained?

Removable fill, open-top access, and bottom drains enable quarterly cleaning. Anti-fouling and anti-bacterial coatings are available. - What about automation and monitoring?

IoT upgrade options allow continuous monitoring of temperature, vibration, water flow and level, with alarms via SMS/APP.

11. Industry Recognition & Corporate Authority

- 500+ successful Air Conditioning Cooling Tower installations since 2003.

- Cooperative partner for ABB, Siemens, CocaCola, PetroChina.

- Products tested by SGS, TUV, and China National Institute of Metrology.

Expert Reference: “Latest developments in corrosion-proof cooling towers have set new benchmarks for lifecycle cost reduction and safety.”—ASHRAE Technical Committee 8.6

12. Contact & Consultation

- Learn more, request technical datasheets, or enquire about your project: Air Conditioning Cooling Tower product page.

- Email: sales@longxuanfrp.com | 24/7 technical hotline: +86-532-8651-3777

References & Further Reading

- MarketsandMarkets Cooling Tower Market Report, 2024

- ASHRAE Technical Resources for Cooling Towers

- HPAC Engineering: Cooling Tower Innovation Overview

- Refrigeration Engineer Forum - Cooling Towers

- Journal of Building Engineering. “Performance Optimization of FRP Cooling Towers”, vol.52, 2023. Read article

- Air Conditioning Cooling Tower - LONGXUAN Product Details

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China