We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Understanding Air Conditioning Cooling Towers: A Comprehensive Overview

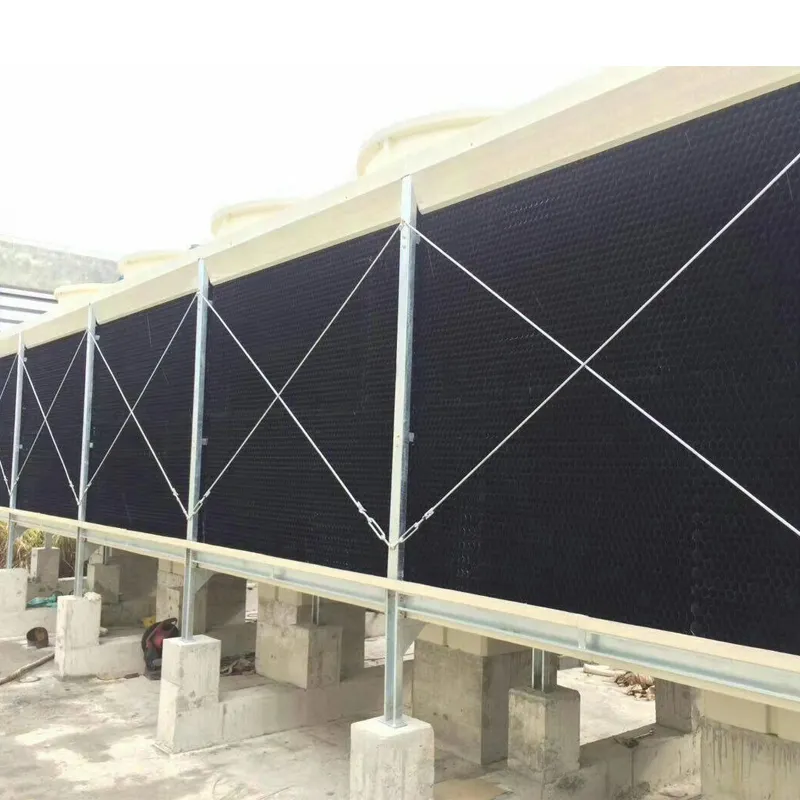

In modern commercial and industrial settings, efficient thermal management is paramount for operational stability and energy efficiency. At the core of many large-scale cooling systems lies the ac cooling tower, a critical component designed to dissipate waste heat from chilled water systems into the atmosphere. This process is fundamental to the functionality of HVAC (Heating, Ventilation, and Air Conditioning) systems, refrigeration cycles, and numerous industrial processes, ensuring optimal performance and longevity of equipment. Cooling towers, particularly those integrated into HVAC systems, play a pivotal role in maintaining comfortable indoor environments and stable process temperatures by continuously rejecting heat absorbed by the chillers. The efficiency of a cooling tower directly impacts the overall Coefficient of Performance (COP) of a refrigeration system, making its selection and maintenance a strategic decision for facility managers and engineers. Understanding the nuances of a cooling tower in a refrigeration system, including its design, operational principles, and technological advancements, is crucial for maximizing energy savings and minimizing environmental impact. Our focus here is to provide an in-depth exploration of Air Conditioning Cooling Towers, covering their essential role, technological specifics, and practical applications, offering insights vital for informed procurement and operational excellence. This detailed discussion aims to equip B2B decision-makers with the knowledge needed to evaluate and implement the most suitable cooling solutions for their specific requirements, emphasizing the long-term benefits of robust and well-engineered systems in diverse operational contexts.

The market for cooling towers HVAC systems is continuously evolving, driven by stringent energy efficiency regulations and increasing demand for sustainable solutions. Contemporary trends highlight a shift towards smarter, more modular, and environmentally friendly cooling tower designs. Innovations include advanced fill materials that enhance heat transfer efficiency, variable frequency drives (VFDs) for optimized fan motor operation, and sophisticated control systems that allow for precise temperature management and energy consumption tracking. Furthermore, there's a growing emphasis on minimizing water consumption through technologies like hybrid cooling towers, which combine evaporative and dry cooling methods, and advanced water treatment solutions to mitigate scaling, corrosion, and biological growth. These advancements not only improve the performance of a cooling tower HVAC system but also contribute significantly to reducing operational costs and environmental footprint. The integration of IoT (Internet of Things) sensors for real-time monitoring and predictive maintenance is another significant trend, enabling proactive management and extending the service life of these critical assets. Such technological leaps ensure that modern Air Conditioning Cooling Tower units are not merely heat rejection devices but integral components of a holistic, energy-efficient building management strategy. The industry is also seeing greater adoption of composite materials like Fiberglass Reinforced Plastic (FRP) for tower construction, offering superior corrosion resistance, lighter weight, and extended durability compared to traditional materials, thereby reducing maintenance burdens and lifecycle costs.

The Core Function of an AC Cooling Tower in Refrigeration Systems

To fully appreciate the role of a cooling tower in a refrigeration system, it's essential to understand the fundamental principles of vapor-compression refrigeration. A typical refrigeration cycle involves a compressor, condenser, expansion valve, and evaporator. The cooling tower specifically interfaces with the condenser, which is responsible for rejecting the heat absorbed by the refrigerant in the evaporator (from the space or process being cooled) plus the heat equivalent of the work done by the compressor. In a water-cooled refrigeration system, hot refrigerant gas from the compressor enters the condenser coils, where it transfers heat to circulating water. This heated water then flows to the cooling tower hvac system, where it is cooled through evaporative cooling. As water cascades down the fill material within the tower, it comes into direct contact with ambient air drawn in by fans. A small portion of the water evaporates, absorbing latent heat from the remaining water, thereby cooling it significantly. This cooled water is then returned to the condenser to absorb more heat, completing the cycle. This continuous heat rejection mechanism is vital for maintaining the low condensing temperatures required for efficient chiller operation, directly impacting the system's power consumption and cooling capacity. The efficiency of this heat exchange process is heavily influenced by factors such as ambient wet-bulb temperature, airflow rates, and the design of the tower's fill media.

The primary function of cooling tower in refrigeration system is thus to facilitate the efficient rejection of heat, ensuring the chiller operates within its optimal parameters. Without an effective ac cooling tower, the condenser pressure would rise significantly, leading to higher compressor power consumption, reduced cooling capacity, and potential equipment damage. The design parameters of a cooling tower, such as cooling capacity (measured in tons of refrigeration or kilowatts), flow rate, and heat rejection rate, are meticulously matched to the chiller's requirements. Moreover, advanced cooling towers incorporate drift eliminators to minimize water loss through entrained droplets, basin sweep systems for sediment removal, and access for easy maintenance, all contributing to long-term reliability and performance. Materials of construction are also critical, with FRP (Fiberglass Reinforced Plastic) being a preferred choice for its exceptional resistance to corrosion, UV radiation, and biological growth, factors common in humid and constantly wet environments. This material choice extends the operational life of the cooling tower and reduces the need for frequent repairs or replacements, offering substantial lifecycle cost savings for industrial and commercial applications.

Manufacturing Excellence and Technical Specifications of Air Conditioning Cooling Towers

The manufacturing process of a high-performance ac cooling tower is a testament to precision engineering and material science. It typically commences with the selection of premium-grade materials, predominantly Fiberglass Reinforced Plastic (FRP) for the casing and structural components, known for its superior strength-to-weight ratio, exceptional corrosion resistance, and longevity in harsh environments. Critical internal components, such as fill media, drift eliminators, and water distribution systems, are often made from PVC or PP, selected for their resistance to chemical degradation and optimal heat transfer characteristics. The manufacturing workflow often involves advanced composite molding techniques, precision cutting, and specialized assembly processes. For instance, large FRP sections might be produced through filament winding or hand lay-up methods, followed by meticulous curing to achieve desired mechanical properties. Metallic components like fan assemblies or motor mounts typically undergo CNC machining for high precision, followed by galvanization or epoxy coating for corrosion protection. Each stage adheres to rigorous quality control protocols, with materials inspected for compliance with ASTM standards and finished components tested for structural integrity and dimensional accuracy.

Quality assurance in the production of an Air Conditioning Cooling Tower is not merely a formality; it is a critical differentiator. Our manufacturing process rigorously follows international standards such as ISO 9001 for quality management and ANSI/ASHRAE Standard 12-2000 for Methods of Testing Remote Mechanical-Draft Evaporative Cooling Equipment. This ensures that every unit not only meets but often exceeds industry benchmarks for performance and safety. Non-destructive testing (NDT) techniques, including ultrasonic testing for material integrity and visual inspections, are routinely applied. The average service life of a well-maintained FRP cooling towers hvac system can range from 20 to 30 years, significantly outperforming units made from conventional materials under similar operating conditions. This extended lifespan translates into a lower total cost of ownership for industries such as petrochemical, power generation, metallurgy, commercial HVAC, and water treatment. In typical application scenarios, such as large commercial buildings or industrial plants, the anti-corrosive properties of FRP ensure consistent performance even when dealing with aggressive water chemistries, while optimized fill designs lead to superior energy efficiency, reducing operational power consumption by up to 15% compared to less advanced models.

Key Technical Parameters of AC Cooling Towers

| Parameter | Typical Range / Value | Significance |

|---|---|---|

| Cooling Capacity | 50 TR to 5000+ TR (Tons of Refrigeration) | Total heat rejected by the tower, matched to chiller load. |

| Water Flow Rate | 15 GPM/TR to 3 GPM/TR | Volume of water circulated per minute, critical for sizing pumps. |

| Inlet Water Temperature | 37°C - 49°C (98.6°F - 120.2°F) | Temperature of water entering the tower from the condenser. |

| Outlet Water Temperature | 32°C - 38°C (89.6°F - 100.4°F) | Desired cooled water temperature returning to the condenser. |

| Wet-Bulb Temperature (Design) | 25°C - 28°C (77°F - 82.4°F) | Ambient air parameter crucial for evaporative cooling efficiency. |

| Approach (to WBT) | 3°C - 8°C (5.4°F - 14.4°F) | Difference between outlet water temp and design wet-bulb temp. Lower is better. |

| Range (ΔT) | 5°C - 10°C (9°F - 18°F) | Difference between inlet and outlet water temperatures. |

| Drift Loss | 0.001% - 0.005% of circulating water | Amount of water lost as entrained droplets, minimized by eliminators. |

| Fan Motor Power | 5 HP to 200+ HP | Energy consumption for air movement, often with VFDs for optimization. |

Application Scenarios and Strategic Advantages

The versatility of an ac cooling tower makes it an indispensable asset across a broad spectrum of industries, extending far beyond conventional HVAC applications. In the petrochemical sector, these towers are crucial for cooling process water used in refineries, chemical plants, and gas processing facilities, where precise temperature control is vital for reaction efficiency and safety. Similarly, in power generation, both conventional thermal and nuclear power plants rely heavily on large-scale cooling towers to dissipate waste heat from turbine condensers, significantly impacting overall plant efficiency and environmental compliance. The metallurgy industry utilizes cooling towers to cool furnaces, rolling mills, and casting equipment, preventing overheating and extending equipment life. Beyond these heavy industries, cooling tower hvac systems are fundamental to the operation of large commercial complexes, data centers, hospitals, and pharmaceutical manufacturing facilities, ensuring stable indoor climates and protecting sensitive electronic equipment or sterile environments. The ability to customize a cooling tower system, factoring in specific environmental conditions like extreme temperatures or corrosive atmospheres, and operational demands, such as varying heat loads or stringent noise limitations, underscores their adaptability.

The technical advantages of modern Air Conditioning Cooling Tower solutions are multifaceted. Foremost is their unparalleled energy efficiency in rejecting large quantities of heat, especially when compared to air-cooled alternatives, leading to substantial reductions in operational electricity costs. This efficiency is largely attributed to the principle of evaporative cooling, which leverages the latent heat of vaporization to achieve lower cooling temperatures than ambient dry-bulb temperatures. Furthermore, the use of high-quality FRP materials ensures exceptional corrosion resistance, significantly reducing maintenance downtime and costs associated with repairing or replacing corroded metal components, a common issue in traditional cooling towers. This inherent durability contributes to an impressive return on investment (ROI) over the long service life of the unit. Advanced designs incorporate features like low-noise fans, high-efficiency fill media for enhanced heat transfer, and robust structural integrity to withstand seismic and wind loads, making them suitable for diverse global installations. Manufacturers also offer modular designs, which allow for easier transportation, assembly, and future expansion, providing flexibility for evolving business needs. These combined advantages position the ac cooling tower as a superior choice for long-term, cost-effective, and environmentally responsible thermal management.

Manufacturer Comparison and Customization Solutions

Choosing the right ac cooling tower manufacturer is a pivotal decision that impacts system performance, longevity, and operational expenditure. While many providers exist, discerning buyers focus on factors such as engineering expertise, material quality, adherence to international standards, after-sales support, and a proven track record. Leading manufacturers often differentiate themselves through innovative designs that optimize energy efficiency, minimize water usage, and reduce noise levels. For instance, some specialize in crossflow designs preferred for lower pump head requirements, while others excel in counterflow towers known for higher thermal efficiency in compact footprints. A comprehensive evaluation involves comparing not just initial purchase costs but also long-term operating costs, including energy consumption, water treatment, and maintenance. Key elements to scrutinize include the type and quality of fill media, fan design (axial vs. centrifugal), motor efficiency, and the robustness of structural components. Reputable manufacturers will provide transparent data sheets, performance curves, and case studies to support their claims, facilitating an informed comparison of various cooling tower hvac system offerings based on specific project requirements and environmental conditions.

Customization is a cornerstone of our approach to delivering optimal Air Conditioning Cooling Tower solutions. Recognizing that every industrial or commercial application presents unique challenges and specifications, we offer bespoke design and manufacturing services tailored to precise client needs. This involves a collaborative process, starting with a detailed assessment of the proposed application, including heat load requirements, available footprint, ambient climatic conditions (e.g., wet-bulb temperatures, wind loads), seismic zone considerations, and specific operational constraints like noise limits or water quality. Our engineering team leverages advanced simulation software to model performance under various scenarios, ensuring the proposed ac cooling tower meets or exceeds all specified parameters. Customization options extend to materials of construction (e.g., specialized FRP composites for extreme chemical resistance), fan types and sizes, motor efficiencies (e.g., IE3/IE4 motors for energy savings), water distribution systems, and even modular design for phased installation or future capacity upgrades. This commitment to tailored solutions ensures that clients receive not just a product, but a fully integrated, high-performance thermal management system perfectly aligned with their operational goals and sustainability targets.

Real-World Application Cases and Client Success Stories

The effectiveness and reliability of an ac cooling tower are best demonstrated through tangible application cases and positive client feedback. Consider a large data center located in a humid climate. Prior to our intervention, the facility struggled with inconsistent server temperatures and high energy bills due to an outdated, inefficient cooling towers hvac system. After a comprehensive site analysis, we designed and installed a custom-engineered FRP Air Conditioning Cooling Tower with high-efficiency drift eliminators and a smart VFD-controlled fan system. The result was a consistent 15% reduction in energy consumption for cooling, a more stable operating temperature for sensitive IT equipment, and a significant decrease in water loss, contributing to lower operational expenditures and an improved PUE (Power Usage Effectiveness) ratio for the data center. This case highlights how precise engineering and material selection can directly translate into measurable operational improvements and cost savings in mission-critical environments. Our commitment to understanding the unique challenges of each client allows us to deliver solutions that not only meet performance criteria but also enhance overall operational sustainability and resilience.

Another notable application involved a major chemical processing plant that required a robust cooling tower hvac system capable of handling corrosive process water and operating continuously under demanding conditions. Traditional metal towers had failed prematurely due to corrosion. We provided a series of modular FRP ac cooling tower units, specifically designed with enhanced chemical resistance properties and easily accessible maintenance points. The modular approach allowed for staggered installation, minimizing plant downtime, and provided flexibility for future capacity expansion. The client reported an immediate improvement in cooling efficiency and, crucially, a dramatic reduction in maintenance frequency and costs associated with corrosion-related failures. This project underscores our capability in delivering durable, high-performance solutions for even the most aggressive industrial environments, offering long-term reliability and significant lifecycle savings. Customer testimonials consistently praise our technical expertise, responsive support, and the long-term value delivered by our Air Conditioning Cooling Tower solutions, reaffirming our position as a trusted partner in industrial thermal management.

Trustworthiness: FAQs, Delivery, and Warranty

Frequently Asked Questions (FAQs) about AC Cooling Towers

Q: What is the average lifespan of an Air Conditioning Cooling Tower manufactured from FRP?

A: With proper maintenance and water treatment, our FRP ac cooling tower units are designed for a service life of 20 to 30 years, significantly longer than traditional galvanized steel towers due to superior corrosion resistance.

Q: How does a cooling tower HVAC system contribute to energy efficiency?

A: Cooling towers reject heat through evaporative cooling, which is far more energy-efficient than air-cooled condensers, especially in hot climates. By achieving lower condenser water temperatures, chillers operate more efficiently, reducing overall power consumption for the entire HVAC system.

Q: What kind of maintenance is required for an ac cooling tower?

A: Regular maintenance includes checking water quality and chemistry, cleaning fill media and spray nozzles, inspecting fans and motors, and ensuring proper water flow. Our systems are designed for easy access to internal components to simplify these routine tasks.

Q: Can your cooling towers be customized for specific industrial applications?

A: Absolutely. We specialize in custom-engineered Air Conditioning Cooling Tower solutions. Our team works closely with clients to design units that meet precise heat rejection requirements, footprint limitations, material compatibility for corrosive fluids, and environmental considerations such as noise levels.

Delivery Schedule and Quality Assurance

Our commitment to efficiency extends from design to delivery. Standard ac cooling tower models typically have a lead time of 6-8 weeks, while custom-engineered solutions may require 10-14 weeks, depending on complexity and material sourcing. We maintain a robust supply chain and utilize advanced project management tools to ensure timely fabrication and dispatch. All products undergo a final comprehensive quality assurance inspection before leaving our facility, including hydrostatic testing of basins and functional checks of fan motors and water distribution systems. This meticulous process minimizes on-site installation challenges and ensures immediate operational readiness upon delivery. Our logistics team coordinates closely with clients to facilitate smooth transportation, whether by land or sea, accommodating specific site access requirements and delivery timelines to ensure a seamless project execution from order placement to operational handover.

Comprehensive Warranty and Customer Support

We stand behind the quality and performance of our Air Conditioning Cooling Tower products with a comprehensive warranty program. Typically, our structural FRP components carry a 5-year warranty against defects in materials and workmanship, while mechanical components such as fans, motors, and gear reducers are covered for 1-2 years, aligning with industry standards. Beyond the warranty period, our dedicated customer support team and network of certified service partners are available to provide technical assistance, spare parts, and on-site maintenance services. We offer various service contracts, including preventive maintenance plans, to ensure the long-term optimal performance and extended lifespan of your cooling towers hvac system. Our commitment to client satisfaction is unwavering, providing peace of mind and ensuring that your investment in a high-quality ac cooling tower delivers sustained value throughout its operational life. Our technical support team is accessible via multiple channels, ready to assist with troubleshooting, operational guidance, and spare part procurement, reinforcing our pledge to unparalleled post-sales service.

References

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) - ASHRAE Handbook: HVAC Systems and Equipment.

- Cooling Technology Institute (CTI) - CTI Standard Specifications and Testing Codes for Cooling Towers.

- International Organization for Standardization (ISO) - ISO 9001: Quality Management Systems.

- U.S. Department of Energy (DOE) - Energy Efficiency and Renewable Energy: Cooling Towers.

- Industrial Refrigeration Handbook - Wilbert F. Stoecker, P.E., Ph.D.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China