We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

- Introduction to FRP Water Tank Manufacturing Industry

- Data-Driven Insights and Technological Advancements

- Competitive Analysis: Leading Companies Comparison

- FRP Pipe Manufacturing: Synergy in Product Lines

- Customization Strategies in FRP Products Manufacturing

- Application Case Studies and Implementation Results

- Future Trends for FRP Water Tank Manufacturer and Customers

(frp water tank manufacturer)

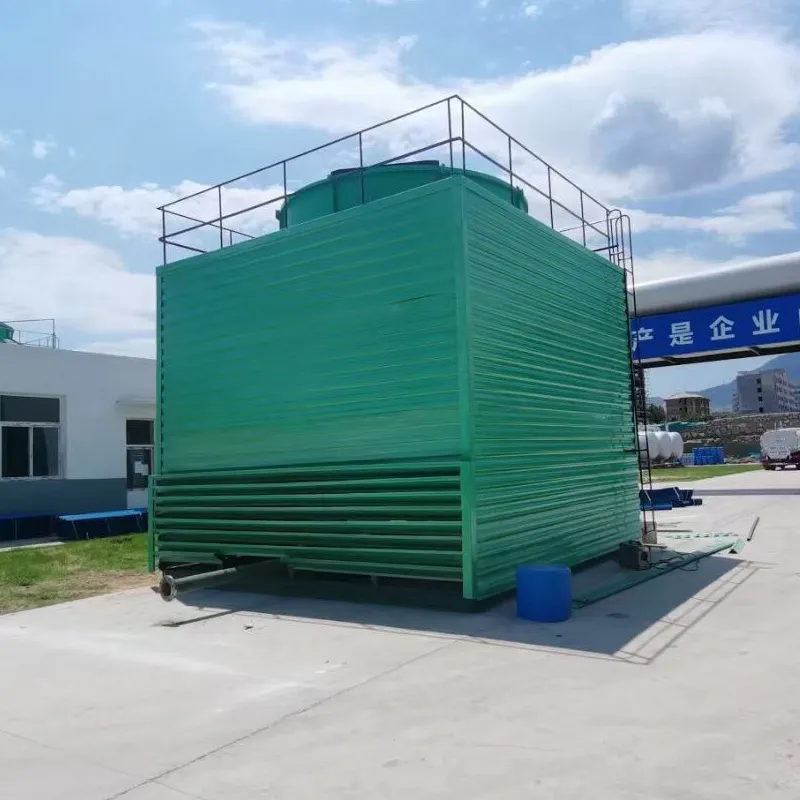

Introduction: The Dynamic Landscape of FRP Water Tank Manufacturer Sector

The FRP water tank manufacturer sector has evolved significantly over the past decade, driven by increasing demands for corrosion-resistant storage solutions in municipal, industrial, and commercial applications. As water scarcity and infrastructure modernization become top priorities globally, the adoption of Fiber Reinforced Plastics (FRP) tanks stands out as a sustainable and efficient alternative to conventional storage options like steel or concrete. This shift is backed by market data: According to a 2023 Global Industry Analysts report, the FRP tank market was valued at nearly $2.7 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2028. The robustness, lightweight nature, and exceptional chemical resistance of FRP products have positioned top manufacturers as key players in critical infrastructure projects worldwide.

Innovative Data and Technical Advantages in FRP Manufacturing

Technological innovation is central to the competitive edge of any FRP products manufacturer. Modern manufacturing processes for FRP water tanks involve cutting-edge resins, advanced fiber weaving techniques, and computer-aided design (CAD) that ensures high structural integrity and longevity. The adoption of vacuum infusion, filament winding, and automated pultrusion process has resulted in FRP tanks with superior mechanical properties, including tensile strengths exceeding 800 MPa and service lifespans of over 35 years with minimal maintenance.

Moreover, sustainability metrics favor FRP, as studies reveal these tanks can lower lifecycle greenhouse emissions by up to 38% compared to metal counterparts. Leak-proof panel assembly designs, modular tank constructions, and embedded smart sensors for real-time condition monitoring further distinguish products from leading FRP water tank manufacturer brands.

Competitive Analysis: Comparing Leading FRP Manufacturers

With increased competition, customers often evaluate FRP tank providers not only on product quality but also on engineering capabilities, delivery timelines, customization, and after-sales service. Below is a comparative table summarizing offerings and technical benchmarks from three global FRP leaders:

| Parameter | Company A | Company B | Company C |

|---|---|---|---|

| Annual Output (units) | 12,000 | 9,800 | 7,500 |

| Product Range | Water tanks, FRP pipes, panels | Tanks & pipes only | Tanks, pipes, GRP fittings |

| Standard Tank Lifespan | 35+ years | 30 years | 28 years |

| In-house R&D Capability | Yes, 14 patents | Limited | Yes, 6 patents |

| Global Export Coverage | 65+ countries | 22+ countries | 34+ countries |

| Lead Time (days) | 15-25 | 18-35 | 20-40 |

| Certifications | ISO 9001, NSF | ISO 9001 | ISO 9001, UL |

This comparison emphasizes the need for comprehensive supplier evaluation, focusing not solely on price but also on industrial certifications, R&D capabilities, and international reach.

Synergies: FRP Pipe Manufacturer Expertise and Product Integration

The synergy between FRP pipe manufacturer capabilities and water tank fabrication presents significant value to infrastructure developers. Integrated solutions allow for seamless delivery of entire hydraulic systems, which includes piping, storage, and fitting components, reducing project lead times and ensuring consistent product quality across downstream applications.

FRP pipes, renowned for their hydraulic smoothness (with a Hazen-Williams C value above 150), chemical inertness, and ability to withstand high internal/external pressure, become natural complements to FRP tanks. Leading manufacturers now deliver prefabricated tank-pipe modules that simplify onsite assembly, expand design choices, and improve water system reliability.

Additionally, multi-variant product lines enable suppliers to address complex customer demands—such as high-pressure fire suppression systems in commercial buildings and large-scale potable water storage in arid climates—with unified engineering standards and support.

Custom Solutions: Tailored Approaches in FRP Products Manufacturer Services

As requirements diversify, a modern frp products manufacturer must prioritize customization and flexible engineering. This includes offering a broad selection of resins (epoxy, vinyl ester, orthophthalic, etc.), fire-retardant formulations, antimicrobial linings for potable applications, and UV-stabilized finishes.

A key differentiator lies in the ability to produce tanks and pipes with specific geometric tolerances, modular expansion capabilities, and integrated access provisions tailored to site conditions. For instance, bolted sectional tank systems are often developed to fit through limited access points and assembled in confined basements or rooftops, while cylindrical units feature integral baffles and supports for earthquake-prone regions.

Advanced digital design tools, such as finite element analysis, aid manufacturers in developing robust yet lightweight products with safety margins up to 2.5 times regulatory requirements. The engineering team’s involvement from design consultation through commissioning ensures optimal specification, installation, and maintenance planning, supporting high ROI and lifecycle performance.

Real-World Applications: Case Studies in Diverse Environments

Demonstrative case studies reveal the breadth and impact of leading FRP solutions. In 2021, a 4,000 m³ sectional FRP water tank was deployed at a Middle Eastern desalination plant, where ambient temperatures routinely exceed 48°C. The tank’s UV-resistant laminate, modular assembly, and integrated monitoring sensors contributed to zero maintenance interventions in the first 24 months—surpassing expectations compared to conventional steel tanks, which typically require annual inspection and repainting.

Another case in Southeast Asia involved the delivery of 3 km of large-diameter FRP pipework to a municipal water project. Here, the minimized joint count and seamless coupling technology slashed onsite installation time by 35%, reducing workforce exposure and project duration.

In North America, FRP tank and pipe systems were selected for a data center cooling project, credited for delivering consistent thermal performance and eliminating corrosion risks associated with chlorinated water circuits. Each example highlights measurable gains in operational efficiency, cost of ownership, and environmental sustainability.

Future Perspective: The Outlook for FRP Water Tank Manufacturer and Buyers

Looking ahead, the FRP water tank manufacturer industry is poised for further transformation, propelled by market globalization, regulatory shifts targeting potable water quality, and customer embrace of digital manufacturing. Intelligent tanks—featuring IoT-enabled leak detection, predictive maintenance modules, and AI-powered optimization—are entering commercial pipelines and will redefine expectations around storage system transparency and resilience.

The cross-pollination between FRP tank, pipe, and comprehensive product manufacturers will foster more holistic solutions, enabling clients in infrastructure, mining, and green building sectors to achieve robust, future-proof water management strategies.

For procurement leaders and project engineers, optimizing vendor relationships based on proven technical expertise, customization agility, and documented application success will ensure strategic investments yield maximum value throughout the asset lifecycle.

(frp water tank manufacturer)

FAQS on frp water tank manufacturer

Q: What services does an FRP water tank manufacturer provide?

A: An FRP water tank manufacturer specializes in designing, fabricating, and installing fiberglass reinforced plastic water tanks. They offer customized solutions based on capacity and usage requirements. Most also provide maintenance and repair services.Q: How does an FRP pipe manufacturer ensure product quality?

A: An FRP pipe manufacturer uses advanced production techniques and quality inspection protocols. They follow international standards to guarantee durability and leak-proof performance. Quality assurance teams conduct regular tests and inspections.Q: What types of FRP products can an FRP products manufacturer supply?

A: An FRP products manufacturer supplies items like tanks, pipes, ducts, gratings, and covers. These products are used in water treatment, chemical storage, and construction. Custom FRP components are also available upon request.Q: Why choose an FRP water tank over traditional tanks?

A: FRP water tanks are lightweight, corrosion-resistant, and have a longer lifespan compared to steel or concrete tanks. They require less maintenance and are suitable for various industries. Installation is quick and cost-effective.Q: Do FRP water tank manufacturers accept custom orders?

A: Yes, most FRP water tank manufacturers offer customization based on size, shape, and application needs. Clients can specify capacity and features required. The manufacturer will provide a tailored solution accordingly.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China