We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

- Introduction to FRP Cable Tray Support: Market Overview & Data

- Technical Advantages of FRP Cable Tray Support Systems

- Comparing Leading FRP Cable Tray Manufacturers

- Customization Options for Diverse Project Requirements

- Spotlight: Perforated FRP Cable Tray Solutions

- Noteworthy Application Cases Across Industries

- Conclusion: FRP Cable Tray Support in Future Infrastructure

(frp cable tray support)

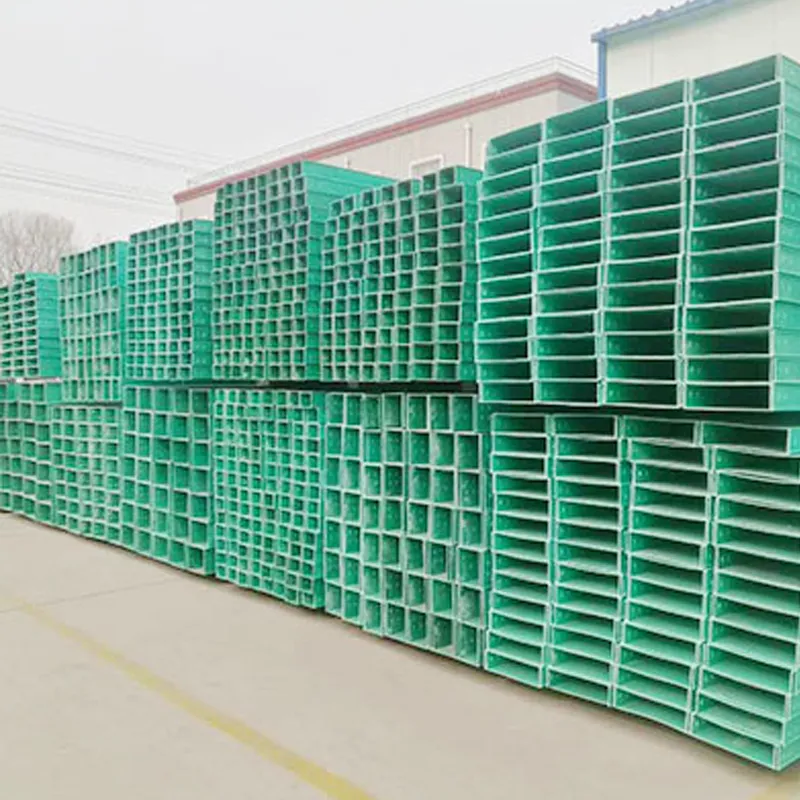

Introduction to FRP Cable Tray Support: Market Overview & Data

In electrical and industrial infrastructure, effective management of cables is non-negotiable for safety, efficiency, and accessibility. FRP cable tray support systems, constructed from high-performance fiberglass reinforced plastics (FRP), are rapidly transforming cable support frameworks worldwide. According to Markets & Markets, the global FRP cable tray market size is projected to grow at a CAGR of 8.1% from 2023 to 2029, reaching an estimated USD 660 million by 2029. The surge can be credited to FRP’s corrosion resistance, strength-to-weight superiority, and long lifespan—features crucial for power, petrochemical, mining, and data center environments. Additionally, over 67% of new cable tray installations in coastal and hydrocarbon-rich regions now prefer FRP over galvanized steel, driven largely by lower maintenance costs and improved safety compliance.

As stake in infrastructure scales, the demand for innovative cable management solutions grows proportionally. Project planners and engineers are consistently evaluating not just up-front expenditure, but the lifecycle value and regulatory fit of materials. Inspections by the National Electrical Code (NEC) have further propelled the replacement of outdated metal trays with FRP cable tray support, enhancing operational uptime and minimizing risk of corrosion-induced failures.

Technical Advantages of FRP Cable Tray Support Systems

The foundation of modern cable routing lies in reliability. FRP cable tray support systems deliver an outstanding balance of mechanical performance and endurance. Notably, the modulus of elasticity for FRP composites can reach up to 40 GPa, rivaling certain metals, yet maintaining a density just 20-30% of conventional steel, resulting in lighter installations and reduced structural load. Their thermal conductivity (approximately 0.25 W/mK) is far lower than metals, supporting enhanced fire performance and personnel safety.

- Corrosion Resistance: Over 20 years of field data shows FRP systems retain up to 90% structural integrity, even in aggressive acid, salt, and moisture environments.

- Electrical Insulation: FRP’s non-conductive nature provides superior protection against accidental shorts and induced currents.

- Low Maintenance: Comparative lifecycle analyses demonstrate maintenance costs for FRP cable trays are 55-65% lower than for metallic trays over a 30-year period.

- Flexibility & Modularity: Custom shapes, sizes, and accessories enable tailored solutions for complex cable routing scenarios without extensive fabrication.

These advantages directly translate to operational uptime, personnel safety, and compliance with evolving international codes (e.g., IEC 61537, NEMA FG-1).

Comparing Leading FRP Cable Tray Manufacturers

A critical specification stage is choosing the appropriate supplier. Here’s a comparative overview of several renowned FRP cable tray manufacturers and their signature products:

| Manufacturer | Location | Product Range | Compliance Standards | Warranty (years) | Avg. Lead Time (weeks) | Custom Color Option |

|---|---|---|---|---|---|---|

| Champion Fiberglass | USA | Ladder, Perforated Trays | NEMA FG-1, IEC 61537 | 25 | 3-4 | Yes |

| Atkore FRE Composites | Canada | Ladder, Solid Bottom, Perforated | NEMA FG-1, UL 568 | 30 | 5 | Yes |

| Salem Steel NA | India | Ladder, Channel, Custom | IEC 61537, ASTM D2310 | 20 | 6 | Limited |

| Fibergrate Composite Structures | USA | Ladder, Trough, Perforated | NEMA FG-1, UL94V-0 | 25 | 4 | Yes |

| B&N FRP Solutions | Germany | Ladder, Perforated, Cable Ducts | IEC 61537, CE | 15 | 7 | On request |

This comparative data highlights that selection factors such as warranty periods, international certifications, lead times, and color customization should align with your project’s locality, technical demands, and long-term goals.

Customization Options for Diverse Project Requirements

Modern FRP cable tray systems are a benchmark not just for durability, but for dynamic customization. Several manufacturers offer advanced configurators allowing end-users to specify tray width, height, rung spacing, loading capacity, UV-resistance, and even color to match safety coding or corporate branding. For specialized industries, custom resin formulations—like fire-retardant or halogen-free blends—address rigorous environmental or safety requirements.

Lengths typically vary from 2 to 6 meters per section, with support for various mounting types such as wall, ceiling, or under-floor embedded applications. Integrations with seismic-resistant bracing, antimicrobial coatings for cleanrooms, or high-load designs (up to 150kg/m) are routine for global FRP cable tray manufacturers. Tailored connectors, expansion joints, and ground kits can further adapt perforated FRP cable tray products to unique facilities, such as pharmaceutical clean zones or heavy chemical plants.

Regardless of the specification, prompt prototyping and digital modeling cut lead times and minimize install errors, while ensuring the tray fits seamlessly in Brownfield or Greenfield site conditions.

Spotlight: Perforated FRP Cable Tray Solutions

Among popular variants, the perforated FRP cable tray stands out for its advantageous design. Strategically placed perforations allow for optimal airflow, essential for cable cooling and dissipation of potentially hazardous vapors. Furthermore, they reduce overall tray weight by up to 25% compared to solid-bottom alternatives, supporting easier installation and lower material costs.

- Enhanced Heat Dissipation: Essential for high-density power or control cabling, preventing premature insulation degradation.

- Efficient Water Drainage: A pivotal factor in outdoor and marine installations exposed to precipitation or washdowns.

- Ease of Cable Access: Facilitates regular additions, inspection, or replacements without entirely dismantling tray covers.

- Optimized Load Rating: Reinforced rungs and side rails counteract any loss of structure from the perforations.

According to user feedback from three large process plants, switching from metallic to perforated FRP trays delivered a 50% drop in maintenance time related to corrosion and facilitated substantially better thermal conditions for data cabling systems.

Noteworthy Application Cases Across Industries

FRP cable tray support solutions span across a wide array of industries, owing to their adaptability and proven performance:

- Power Generation Facilities: Thermal, hydroelectric, and solar power stations employ FRP trays as their primary cable management backbone due to their high dielectric strength and ease of maintenance in corrosive cooling tower areas.

- Chemical Processing Plants: At a US Gulf Coast refining center, an installation of over 24 km of FRP trays has operated since 2010 with only routine inspection maintenance, outperforming legacy steel trays replaced after just 7 years.

- Data Centers: The world’s largest hyperscale facilities now standardize perforated FRP cable tray on overhead tracks, maintaining airflow for power and fiber cable clusters while preventing induction losses and overheating.

- Wastewater Treatment: FRP’s long-term chemical and water resistance makes it a default for cable routing in tank farms, UV filtration systems, and pump areas — notably reducing replacement rate by over 60% vs. metallic trays.

- Marine and Offshore Platforms: The Norwegian North Sea’s largest FPSO vessel uses exclusively FRP cable tray support, eliminating downtime attributed to saltwater corrosion found in metal systems over decades of operation.

Each of these use cases exemplifies significant reductions in both maintenance costs and unplanned downtime, highlighting the real-world ROI of FRP-based systems.

Conclusion: FRP Cable Tray Support in Future Infrastructure

As industries continue to advance their safety, efficiency, and sustainability goals, the role of FRP cable tray support will only become more vital. Both established and emerging FRP cable tray manufacturers are investing in automation, eco-friendly resin systems, and smart tray monitoring for predictive maintenance. Innovation in areas such as digitally encoded trays for asset tracking or advanced modular connectors is on the horizon, further integrating cable tray systems into smart plant infrastructure.

Ultimately, thoughtfully engineered FRP cable tray support platforms empower organizations to meet stringent industry standards, minimize environmental impact, and achieve operational excellence—across all sectors where reliable cable management is non-negotiable.

(frp cable tray support)

FAQS on frp cable tray support

Q: What is an FRP cable tray support?

A: An FRP cable tray support is a structural element designed to hold and secure FRP (Fiber Reinforced Plastic) cable trays in place. It provides stability and strength while resisting corrosion and chemicals. FRP cable tray supports are ideal for harsh or outdoor environments.Q: Why should I choose FRP cable tray manufacturers over traditional ones?

A: FRP cable tray manufacturers offer products that are lightweight, non-conductive, and corrosion-resistant. Their trays require less maintenance than metal alternatives. This makes them suitable for industrial and outdoor applications.Q: What are the main advantages of perforated FRP cable trays?

A: Perforated FRP cable trays allow better air circulation and heat dissipation for cables. They reduce the risk of cable overheating and are lightweight yet sturdy. Their perforated design also facilitates easy cable management.Q: How do I select the right FRP cable tray support for my project?

A: Consider the load requirements, tray width, environmental conditions, and installation method. Consulting FRP cable tray manufacturers can help you find the best support for your needs. Always ensure compatibility with your chosen cable tray type.Q: Are FRP cable tray supports suitable for use in corrosive environments?

A: Yes, FRP cable tray supports are highly resistant to corrosion from chemicals, moisture, and salt. This makes them ideal for use in industries like chemical processing and offshore platforms. Their durability ensures long service life with minimal maintenance.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China