We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

The Strategic Advantage of Evaporative Condensers in Modern Industrial Processes

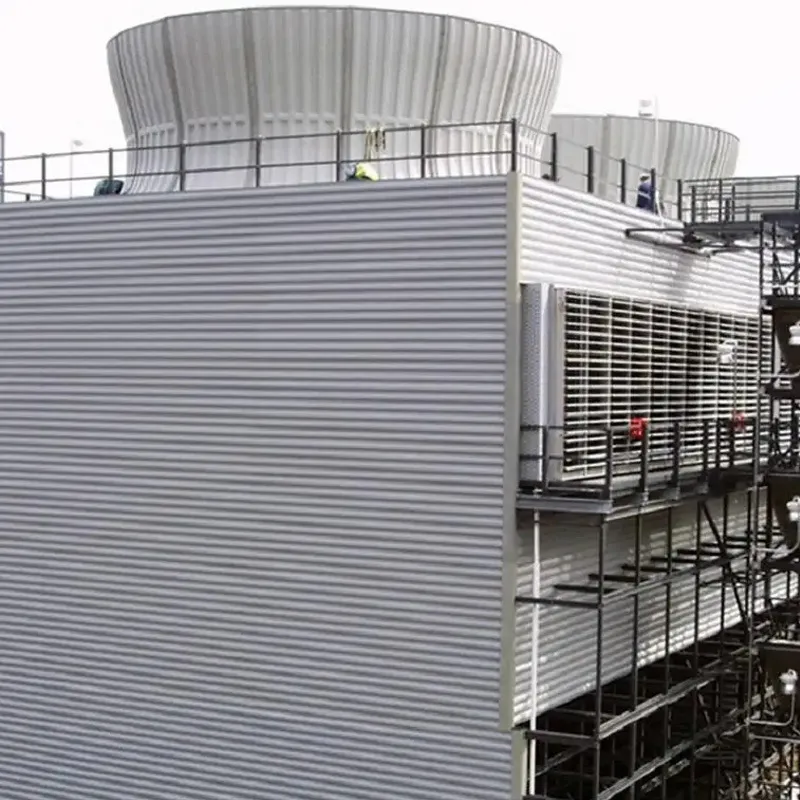

In an era defined by the imperative for sustainable operations and enhanced energy efficiency, the role of advanced heat rejection technologies has become more critical than ever. Industries ranging from petrochemical and power generation to food processing and HVAC systems are continuously seeking solutions that offer superior thermal performance while minimizing environmental impact and operational costs. Among these innovations, the evaporative condenser stands out as a highly efficient and environmentally conscious choice. Unlike traditional air-cooled or water-cooled systems, an evaporative condenser leverages the principle of latent heat of vaporization, achieving significantly lower condensing temperatures and thus optimizing system performance. This technology facilitates the rejection of heat by evaporating a small portion of circulated water directly onto heat exchange coils, leading to a much more effective heat transfer process, especially beneficial in environments where water conservation and energy savings are paramount. Our deep expertise in thermal management solutions allows us to deploy these units with precision, ensuring peak operational efficiency and long-term reliability for demanding industrial applications.

The increasing adoption of this technology is a testament to its compelling advantages. As global energy prices fluctuate and regulatory pressures intensify regarding greenhouse gas emissions and water usage, the strategic investment in an evaporative condenser offers a robust pathway to achieving both economic viability and ecological responsibility. Modern industrial setups demand robust, reliable, and highly efficient cooling systems that can withstand rigorous operating conditions while delivering consistent performance. Our commitment to innovation ensures that our evaporative condenser solutions are not merely components but integrated systems designed to elevate overall plant efficiency. We provide comprehensive design, manufacturing, and support services to ensure these critical assets perform optimally throughout their lifecycle, contributing significantly to reduced energy consumption and improved process stability across various complex industrial ecosystems.

Core Technology and Operating Principles of Evaporative Condensers

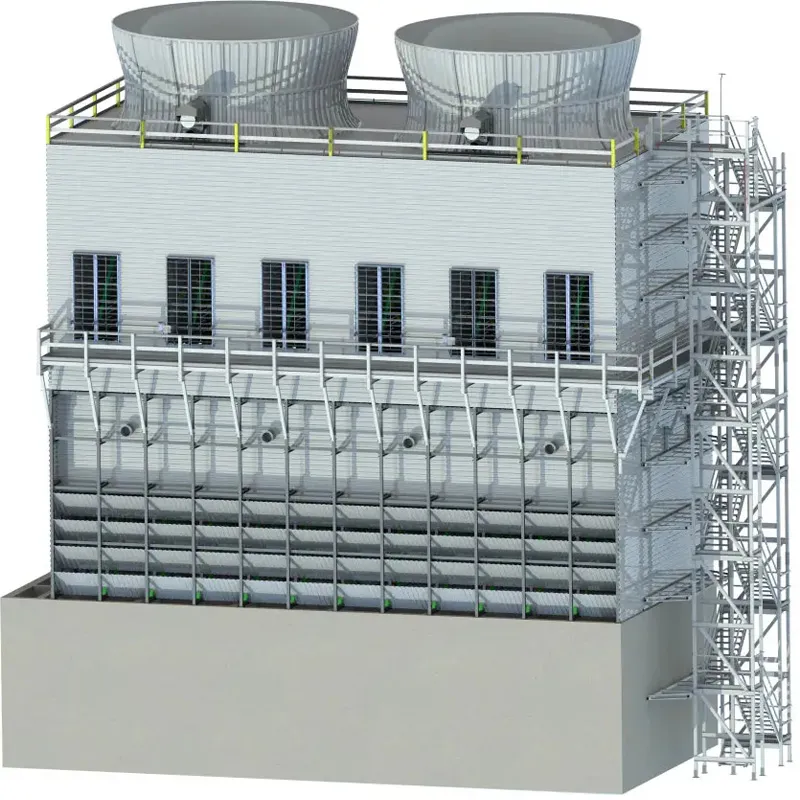

Understanding the fundamental operational principles of an evaporative condenser is key to appreciating its efficiency. At its heart, the system functions by combining the principles of a cooling tower and a shell-and-tube condenser. Refrigerant vapor from the process enters the heat exchange coil, which is continuously wetted by a spray water system. Simultaneously, ambient air is drawn upwards through the unit by powerful fans, flowing counter-current to the falling spray water. As the air passes over the wetted coil surface, a small portion of the spray water evaporates. This evaporation process, which relies on the latent heat of vaporization, rapidly absorbs heat from the refrigerant vapor inside the coils. This interaction cools the refrigerant vapor, causing it to condense back into a liquid state. The heat rejection efficiency is directly proportional to the wet-bulb temperature of the incoming air, allowing for significantly lower condensing temperatures compared to dry-bulb dependent air-cooled systems, translating into higher system Coefficients of Performance (COPs) and lower power consumption for the compressor.

Key components contribute to this sophisticated heat transfer. The robust coil section, often constructed from high-quality steel or stainless steel, is designed for maximum surface area and efficient heat exchange. The spray pump ensures consistent water distribution over the coils, while high-efficiency axial or centrifugal fans facilitate optimal airflow. Drift eliminators, positioned at the air outlet, are crucial for minimizing water droplet carryover, thus conserving water and preventing the release of aerosols. The sump or basin collects the unevaporated spray water for recirculation, and a bleed-off system helps manage dissolved solids to prevent scaling. This intricate synergy of components ensures reliable and energy-efficient heat rejection, making the evaporative condenser a cornerstone technology for energy-intensive industrial applications where precise temperature control and operational longevity are paramount. Our engineering designs prioritize ease of maintenance and long-term durability, ensuring a maximized return on investment for our clients.

Manufacturing Excellence and Quality Assurance

The performance and longevity of an evaporative condenser are intrinsically linked to the precision of its manufacturing process and the quality of its components. We adhere to stringent manufacturing protocols, commencing with the meticulous selection of raw materials. High-grade hot-dip galvanized steel is commonly used for the casing and structural elements, offering excellent corrosion resistance, while heat exchange coils are typically constructed from seamless steel tubes (e.g., ASTM A53/A106) or stainless steel (e.g., SS304/SS316) for superior thermal conductivity and resistance to refrigerant and water-side corrosion. Specialized manufacturing processes include advanced robotic welding for coil integrity, precision CNC machining for component accuracy, and multi-stage surface treatment to enhance durability. Each component, from fan blades to spray nozzles, undergoes rigorous inspection to meet our exacting standards. Our fabrication facilities operate under certified quality management systems, including ISO 9001:2015, ensuring consistency and traceability throughout the production cycle. This dedication to quality ensures that every unit delivered is built for resilience and optimal performance in demanding industrial environments.

Beyond material selection and fabrication, our commitment to quality extends to comprehensive testing and adherence to international standards. Finished evaporative condenser units undergo hydrostatic pressure testing for coil integrity, air balancing tests for fan efficiency, and full operational simulations to verify cooling capacity and energy consumption. We also ensure compliance with critical industry standards such as CTI (Cooling Technology Institute) for thermal performance ratings, ASME for pressure vessel design, and ANSI for general engineering practices. This multi-layered quality control framework guarantees that our evaporative condensers provide an extended service life, typically exceeding 20-25 years with proper maintenance, significantly reducing total cost of ownership. Our extensive experience in delivering solutions for industries like petrochemical, metallurgy, and water treatment underscores our capability to design and produce units that not only meet but exceed the stringent requirements for energy efficiency and anti-corrosion properties, even in aggressive operating conditions.

Key Technical Parameters & Performance Metrics

Selecting the right evaporative condenser requires a thorough understanding of its technical specifications and how they align with specific application demands. Critical parameters include cooling capacity (ranging from hundreds to thousands of refrigeration tons), airflow rates (CMM/CFM), total heat rejection (kW), and fan power consumption (kW). The coil material and design, such as serpentine or parallel flow configurations, significantly influence the heat transfer coefficient and pressure drop. Furthermore, considerations like unit footprint, operational weight, and noise levels are crucial for integration into existing plant layouts and compliance with environmental regulations. Our engineering team meticulously designs each unit to optimize these parameters for maximum efficiency, factoring in site-specific wet-bulb temperatures and load profiles to ensure optimal condensing temperatures and minimal power usage. This detailed approach ensures that every evaporative condensing unit we provide is perfectly matched to the operational requirements, delivering reliable and consistent performance even under varying ambient conditions.

Below is a table illustrating typical parameters for a range of industrial-grade evaporative condenser units. These values are indicative and can vary based on specific design, materials, and operating conditions. Understanding these metrics is vital for projecting energy savings, evaluating space requirements, and ensuring the system can handle peak thermal loads efficiently. Our pre-sales consultancy includes detailed technical discussions to define these parameters precisely, offering customized solutions that prioritize long-term operational cost savings and reliability.

| Parameter | Unit A (Small-Mid) | Unit B (Mid-Large) | Unit C (Large Industrial) |

|---|---|---|---|

| Refrigeration Capacity (TR) | 50 - 200 | 200 - 800 | 800 - 3000+ |

| Total Heat Rejection (kW) | 175 - 700 | 700 - 2800 | 2800 - 10500+ |

| Airflow Rate (CMM / CFM) | 20,000 - 80,000 / 7,000 - 28,000 | 80,000 - 320,000 / 28,000 - 113,000 | 320,000 - 1,200,000+ / 113,000 - 425,000+ |

| Fan Motor Power (kW) | 5.5 - 22 | 22 - 75 | 75 - 200+ |

| Water Pump Power (kW) | 0.75 - 5.5 | 5.5 - 18.5 | 18.5 - 55+ |

| Typical Footprint (m²) | 5 - 15 | 15 - 40 | 40 - 120+ |

| Coil Material Options | Hot-dip Galvanized Steel, SS304 | Hot-dip Galvanized Steel, SS304, SS316 | SS304, SS316, Titanium (custom) |

Application Scenarios Across Diverse Industries

The versatility and efficiency of evaporative condenser units make them indispensable across a broad spectrum of industrial applications. In the petrochemical industry, they are critical for maintaining precise temperatures in chemical processes, gas liquefaction, and refining, where consistent and low condensing temperatures directly impact product purity and overall plant safety. For the metallurgy sector, these condensers support critical cooling needs in steel mills, foundries, and non-ferrous metal production, managing the heat generated from high-temperature furnaces and casting operations. The substantial energy savings offered by evaporative cooling makes them a preferred choice over traditional methods, especially given the high energy demands of these industries. Furthermore, in large-scale HVAC and commercial refrigeration, the evaporative condensing unit provides a robust solution for supermarket refrigeration, cold storage, and comfort cooling in large buildings, ensuring stable indoor climates and product integrity while reducing operational costs.

The power generation industry utilizes evaporative condensers for turbine exhaust steam condensation in smaller power plants or for auxiliary cooling loops, contributing to improved cycle efficiency. In water treatment plants and municipal water supply systems, they play a role in maintaining optimal operating temperatures for pump stations and various process cooling needs. Their ability to deliver lower condensing temperatures compared to air-cooled systems, especially in regions with favorable wet-bulb temperatures, translates into significant energy savings for compressors, which are often the largest energy consumers in refrigeration and industrial cooling cycles. The anti-corrosion properties of properly selected materials, such as hot-dip galvanized or stainless steel, ensure long-term reliability even in challenging industrial environments, providing a sustainable and cost-effective heat rejection solution for diverse and demanding operational contexts. Our expertise spans these varied sectors, allowing us to tailor solutions precisely to unique industrial challenges.

Comparative Analysis: Evaporative vs. Other Condensing Technologies

When evaluating heat rejection solutions, businesses often weigh the merits of evaporative condenser against air-cooled condensers and water-cooled systems (requiring a separate cooling tower). The primary advantage of the evaporative type lies in its superior energy efficiency. By utilizing latent heat transfer, an evaporative condenser can achieve condensing temperatures closer to the ambient wet-bulb temperature, which is often significantly lower than the dry-bulb temperature, the driving force for air-cooled systems. This lower condensing temperature directly translates to reduced compressor power consumption, leading to substantial operational cost savings, often 15-20% lower than comparable air-cooled systems. While water-cooled systems with cooling towers offer similar thermal performance, the integrated design of an evaporative condenser means a smaller footprint and simplified piping, reducing installation complexity and space requirements. Conversely, air-cooled systems require no water, making them suitable for water-scarce regions, but at the cost of higher energy consumption and larger coil surface areas.

Another crucial aspect in this comparison is the overall footprint and maintenance considerations. An evaporative condenser typically occupies a smaller physical space for the same cooling capacity compared to an air-cooled counterpart, making it ideal for sites with limited real estate. While evaporative systems do require water treatment to prevent scaling and biological growth, advancements in water management technologies have made these systems increasingly low-maintenance. The choice between technologies often boils down to a balance of energy efficiency, water availability and cost, space constraints, and long-term operational expenditures. The decision for an evaporative surface condenser or a complete unit should be made after a comprehensive cost-benefit analysis, factoring in local environmental conditions and utility rates. Our technical team assists clients in this detailed evaluation, providing clear comparisons to inform the most economically and environmentally sound investment.

| Feature | Evaporative Condenser | Air-Cooled Condenser | Water-Cooled (with Cooling Tower) |

|---|---|---|---|

| Energy Efficiency (Compressor) | High (Lower Condensing Temp) | Moderate (Higher Condensing Temp) | High (Lower Condensing Temp) |

| Water Consumption | Moderate (Evaporative Loss) | None | Moderate (Evaporative Loss) |

| Footprint per Capacity | Small/Compact | Large | Small (condenser) + Moderate (tower) |

| Initial Investment | Moderate-High | Moderate | Moderate-High (two separate units) |

| Maintenance Complexity | Moderate (Water Treatment) | Low | Moderate (Water Treatment) |

| Noise Level | Moderate | Moderate-High (for large units) | Moderate |

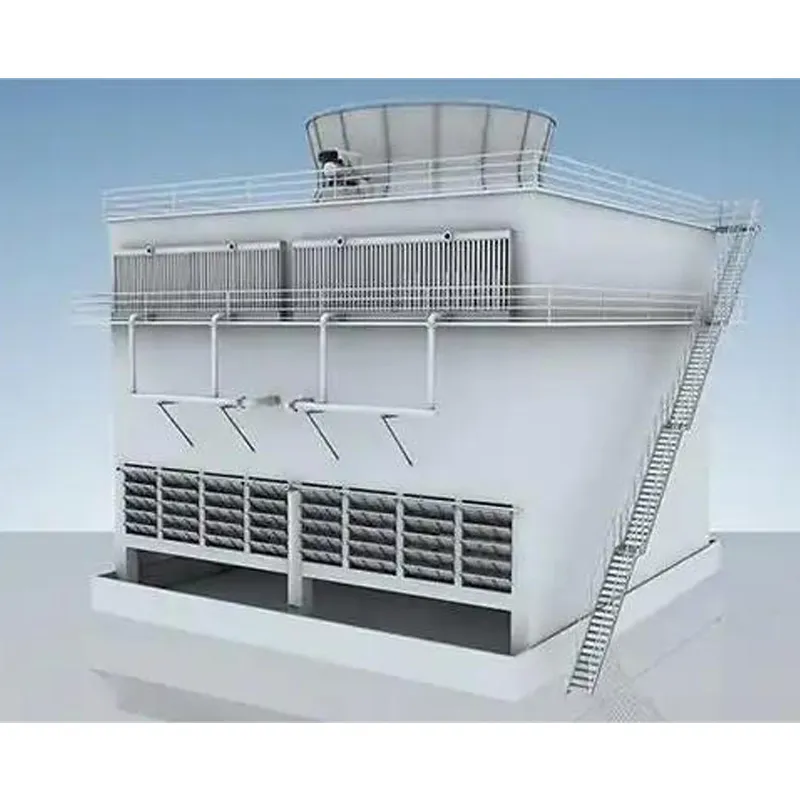

Customization and Engineered Solutions for Optimal Performance

Recognizing that every industrial application presents unique challenges and requirements, our approach to providing evaporative condenser solutions is centered on bespoke engineering. We don't offer a one-size-fits-all product; instead, we collaborate closely with our clients to understand their specific operational parameters, space constraints, ambient environmental conditions, and future expansion plans. This detailed consultation allows us to design and manufacture custom evaporative condensers that are perfectly integrated into their existing or new infrastructure. Customization options extend to coil materials (e.g., SS316 for corrosive environments, titanium for extreme cases), fan types (axial for higher airflow, centrifugal for static pressure), sound attenuation packages for noise-sensitive areas, and specialized coatings for enhanced corrosion protection. Our engineering capabilities enable us to simulate performance under various load conditions, ensuring the proposed solution meets efficiency targets and operational reliability requirements. This commitment to tailored design maximizes the potential for energy savings and ensures seamless integration with client processes.

Furthermore, we provide comprehensive support for integrating the evaporative condenser into complex industrial systems, including control system compatibility, structural considerations, and maintenance access. Our expertise extends beyond unit manufacturing to encompass full-cycle project support, from initial feasibility studies and detailed design to installation guidance and commissioning. For highly specific requirements, such as those involving specialized refrigerants or extreme operating temperatures, we are capable of designing advanced evaporative surface condenser configurations. This bespoke approach ensures that the total cost of ownership is minimized through optimized energy consumption, reduced maintenance needs, and an extended operational lifespan. Our proven track record in delivering customized, high-performance solutions across various industries underscores our capability as a trusted partner in advanced thermal management.

Real-World Applications and Success Stories

Our portfolio includes numerous successful deployments of evaporative condenser units across a diverse range of industries, each demonstrating the tangible benefits of this advanced technology. For a leading petrochemical complex, we engineered a large-capacity evaporative condensing unit to handle the heat rejection from their critical ethylene production process. The customized design, featuring enhanced corrosion resistance for the coil materials and optimized fan configurations, resulted in a 17% reduction in energy consumption for the refrigeration compressors, exceeding their projected savings targets and significantly reducing their operational carbon footprint. In another instance, a major food processing plant leveraged our specialized evaporative condenser units for their cold storage facilities. The reliable, low-temperature condensing enabled them to maintain precise temperature control for perishable goods, drastically reducing spoilage rates and improving product quality, alongside achieving a substantial reduction in energy bills, which was critical for their profit margins.

Furthermore, our solutions have played a pivotal role in the metal manufacturing industry. A large steel mill replaced their aging air-cooled systems with our robust evaporative condenser units, specifically designed to withstand the harsh conditions of their smelting and rolling processes. The immediate benefits included improved process cooling stability, which translated into higher quality metal products and reduced downtime. The significantly lower condensing temperatures achieved by the evaporative system allowed their chillers to operate more efficiently, contributing to substantial energy savings across their entire cooling infrastructure. These real-world examples highlight our capacity to not only provide technically superior equipment but also to deliver quantifiable operational improvements and long-term value. Our commitment to post-installation support ensures that these benefits are sustained throughout the equipment's lifespan, demonstrating our dedication to client success and our authority in industrial thermal management.

Investing in an Evaporative Condenser: Considerations & Cost-Benefit

The decision to invest in an evaporative condenser is a strategic one that extends beyond the initial purchase price. While the upfront evaporative condenser price might be marginally higher than that of a conventional air-cooled system for a comparable capacity, the long-term operational savings often far outweigh this difference. The primary driver of these savings is the significantly lower power consumption of the associated refrigeration compressors, owing to the lower condensing temperatures achieved. Over the typical 20-25 year lifespan of a well-maintained evaporative condenser, these energy savings can amount to millions in reduced utility bills, especially for large-scale industrial operations. Factors influencing the total evaporative condenser price include cooling capacity, material specifications (e.g., galvanized steel vs. stainless steel coils), additional features (e.g., low-noise fans, integrated water treatment), and customization requirements. It's crucial for procurement decision-makers to consider the total cost of ownership (TCO) rather than just the capital expenditure.

Beyond direct financial savings, investing in an evaporative condenser also brings substantial environmental benefits, contributing to corporate sustainability goals. Reduced energy consumption leads to lower greenhouse gas emissions, and advanced water treatment solutions minimize water consumption and blowdown. For regions with high electricity tariffs or strict environmental regulations, the return on investment (ROI) for an evaporative condenser can be exceptionally attractive, often payback periods of 2-5 years. Our comprehensive proposal includes a detailed cost-benefit analysis, outlining the estimated energy savings, water usage, and potential environmental incentives. We also provide transparent information regarding delivery cycles (typically 8-16 weeks depending on customization) and robust warranty commitments, offering peace of mind to our clients. Our dedicated customer support team is available for technical assistance, spare parts, and troubleshooting, ensuring seamless operation throughout the unit's long service life.

Frequently Asked Questions (FAQ) about Evaporative Condensers

-

Q1: How does an evaporative condenser save energy compared to an air-cooled system?

A1: An evaporative condenser utilizes the principle of evaporative cooling, which relies on the wet-bulb temperature of the air. The wet-bulb temperature is almost always lower than the dry-bulb temperature (which air-cooled systems depend on). This lower condensing temperature allows the compressor in the refrigeration or process cooling system to operate more efficiently, consuming less power for the same cooling load. The energy savings can range from 15% to 25% or more depending on ambient conditions and system design.

-

Q2: What is the typical water consumption of an evaporative condenser?

A2: Water consumption primarily comes from evaporation, drift loss, and bleed-off (blowdown). Evaporation loss is inherent to the process and depends on the heat rejected. Drift loss is minimal due to efficient drift eliminators (typically less than 0.001% of circulating water flow). Bleed-off is necessary to control the concentration of dissolved solids and prevent scaling; its rate depends on water quality and cycles of concentration. While water is consumed, modern units are designed for optimal water efficiency, and advancements in water treatment further minimize usage.

-

Q3: What maintenance is required for an evaporative condensing unit?

A3: Regular maintenance includes checking and cleaning spray nozzles, inspecting and cleaning the coil surface, maintaining proper water chemistry through a robust water treatment program (to prevent scaling, corrosion, and biological growth), lubricating fan bearings, and checking drive belts (if applicable). Annual inspections and periodic deep cleaning ensure optimal performance and extend the unit's lifespan. Our service manuals provide detailed maintenance schedules, and our support team can offer training or service contracts.

-

Q4: What is the expected service life of your evaporative condenser units?

A4: With proper installation, regular maintenance, and effective water treatment, our evaporative condenser units are designed for a robust service life of 20 to 25 years or even longer. The use of high-quality materials such as hot-dip galvanized steel, stainless steel coils, and durable FRP components significantly contributes to their longevity, even in challenging industrial environments. Our quality assurance processes and adherence to international standards ensure maximum durability and reliability.

-

Q5: What are your typical delivery periods and warranty terms?

A5: Standard evaporative condensing unit models typically have a delivery period of 8-12 weeks from order confirmation. Highly customized or very large industrial units may require 12-16 weeks. We offer a comprehensive warranty, usually 12-18 months from commissioning or 24 months from shipment, covering defects in materials and workmanship. Specific terms are detailed in our sales agreements. We also provide long-term after-sales support, including spare parts availability and technical assistance.

Conclusion: Pioneering Sustainable Industrial Cooling

The evaporative condenser represents a pinnacle in industrial heat rejection technology, offering unparalleled energy efficiency, significant operational cost savings, and a reduced environmental footprint. From enhancing the performance of refrigeration systems in food and beverage processing to optimizing critical cooling loops in petrochemical and power generation facilities, its versatility and robust design make it an indispensable asset for modern industries striving for both economic viability and ecological responsibility. Our commitment to engineering excellence, adherence to rigorous quality standards (ISO, ANSI, CTI), and provision of customized solutions ensure that each evaporative condenser we deliver is not just a piece of equipment but a long-term strategic investment. We partner with our clients to navigate the complexities of industrial cooling, providing expert guidance from initial consultation and design to installation support and post-sales service, ensuring maximum uptime and performance for your operations.

As industries continue to evolve, facing increasing pressures to optimize resources and reduce their environmental impact, the demand for sophisticated and sustainable cooling solutions will only grow. The evaporative condenser, with its proven track record of superior thermal performance and efficiency gains, is perfectly positioned to meet these challenges. By choosing our expertly engineered evaporative condenser units, businesses can achieve lower utility bills, enhance process stability, and contribute to a more sustainable future. We are dedicated to pushing the boundaries of thermal management technology, ensuring our clients remain at the forefront of efficiency and environmental stewardship.

References

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). ASHRAE Handbook—HVAC Systems and Equipment.

- Cooling Technology Institute (CTI). CTI Standards and Specifications for Thermal Performance Testing.

- International Organization for Standardization (ISO). ISO 9001:2015 Quality Management Systems – Requirements.

- US Department of Energy (DOE). Industrial Technologies Program: Pumping Systems Assessment Tool.

- Journal of Engineering for Industry. Recent Advances in Heat Transfer Technologies for Industrial Applications.

Prev This is the first article

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China