We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Understanding Seawater Cooling Tower Technology in Industrial Applications

Industrial operations, particularly those with significant thermal loads such as power generation, petrochemical processing, and metallurgy, critically rely on efficient heat rejection systems. Among the various solutions available, the seawater cooling tower stands as a paramount technology, especially for facilities located in coastal regions or those with access to abundant saline water sources. Unlike conventional fresh water cooling systems, these specialized towers are engineered to withstand the corrosive and scaling challenges posed by seawater, offering a sustainable and cost-effective method for dissipating waste heat. The design and material selection for a seawater cooling tower are critical, necessitating advanced corrosion-resistant components and robust structural integrity to ensure longevity and optimal performance in harsh marine environments. This includes the meticulous selection of fiberglass reinforced plastic (FRP) composites, specialized coatings, and non-corroding internal components, all of which contribute to the extended operational life and reduced maintenance requirements. The efficacy of a seawater cooling tower in managing large volumes of heat is unmatched, particularly in large-scale industrial plants where process stability and energy efficiency are directly linked to effective cooling. The strategic implementation of such towers not only mitigates reliance on dwindling freshwater resources but also opens up new possibilities for industrial expansion in water-stressed regions, positioning this technology as a cornerstone for future sustainable industrial development.

The demand for robust and efficient cooling solutions continues to rise with global industrialization and increasing energy consumption. This trend underscores the importance of innovations in cooling technologies, including advancements in the design and operation of seawater cooling tower systems. A notable alternative or complement to a cooling tower is a spray pond, which utilizes evaporative cooling over a large surface area. However, compared to a spray pond and cooling tower combination, a dedicated seawater cooling tower typically offers superior cooling efficiency, reduced land footprint, and better control over the cooling process, making it highly suitable for large-scale thermal power plant cooling tower applications and other heavy industries where space is a premium and precise temperature control is essential. The complex interplay of thermodynamic principles, fluid dynamics, and material science underpins the design of these systems, ensuring they can handle varying thermal loads and environmental conditions without compromising structural integrity or performance. Furthermore, the integration of smart monitoring and control systems allows for real-time optimization of the cooling process, minimizing energy consumption and operational costs. This adaptability makes the seawater cooling tower an ideal choice for diverse industrial requirements, ranging from power generation to chemical processing and desalination plants, where reliable and consistent cooling is indispensable for maintaining operational efficiency and safety.

Manufacturing Process and Quality Assurance for Seawater Cooling Towers

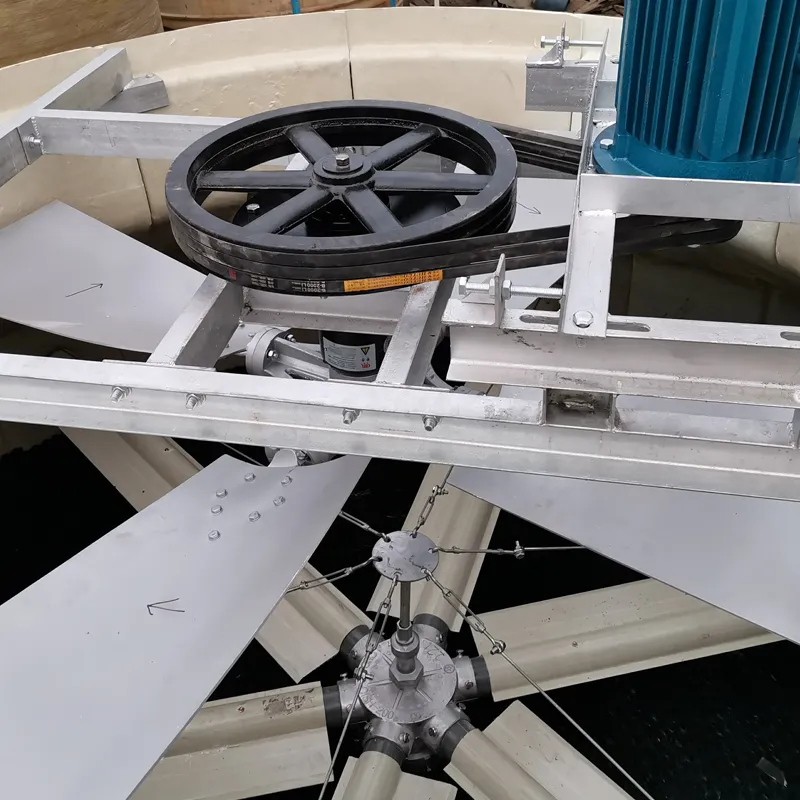

The manufacturing of a high-performance seawater cooling tower involves a multi-stage, precision-engineered process designed to ensure durability, efficiency, and resistance to the corrosive nature of saline water. The journey begins with the selection of premium-grade materials, primarily specialized Fiberglass Reinforced Plastic (FRP) composites, which are selected for their exceptional corrosion resistance, high strength-to-weight ratio, and long service life. Unlike traditional steel structures that require extensive galvanization and periodic coating, FRP components for a true water cooling tower eliminate concerns about rust and galvanic corrosion, which are prevalent issues in marine environments. The manufacturing process often incorporates advanced techniques such as filament winding for structural components, ensuring uniform strength and density, and contact molding or spray-up methods for intricate parts like fill media and drift eliminators. These processes are meticulously controlled to achieve specific wall thicknesses and material compositions. Each component, from the main casing to the internal fill and fan stack, undergoes rigorous quality control inspections at every stage, from raw material incoming to final assembly. For instance, critical components might undergo CNC machining for precise dimensions, followed by non-destructive testing (NDT) to detect any internal flaws.

Throughout the fabrication of a seawater cooling tower, adherence to international standards such as ISO 9001 for quality management and ANSI/CTI (Cooling Technology Institute) for cooling tower performance is paramount. Each module and sub-assembly is subjected to hydrostatic pressure tests for leak integrity, dimensional accuracy checks, and visual inspections for surface finish and structural integrity. Critical elements like the water distribution system and fan assembly are individually tested for flow rate consistency and vibration levels, respectively, ensuring optimal operational parameters once installed. The manufacturing excellence also extends to the specific anti-corrosion treatments applied to any metallic components, such as stainless steel hardware (e.g., SS316L or duplex stainless steel) and specialized protective coatings for motors and gearboxes, further extending the overall lifespan of the seawater cooling tower. The estimated service life for well-maintained FRP cooling towers in harsh marine environments typically exceeds 25-30 years, significantly reducing the total cost of ownership over the operational lifespan. The robust design and manufacturing ensure that these cooling towers are highly suitable for demanding industries such as petrochemical, metallurgical, power generation (specifically as a thermal power plant cooling tower), and municipal water and wastewater treatment, where continuous and reliable cooling is indispensable for process stability and environmental compliance. Our commitment to these stringent manufacturing processes and quality checks ensures that every Circular Cooling Tower delivered represents the pinnacle of reliability and performance in saline cooling applications.

Technical Parameters and Performance Insights

Understanding the critical technical parameters of a seawater cooling tower is essential for optimizing its integration into industrial processes. These parameters define the tower's capacity, efficiency, and operational stability. Key specifications include cooling capacity (measured in Tons of Refrigeration or MW), water flow rate (GPM or m³/h), hot water temperature, cold water temperature, wet-bulb temperature, fan motor power (kW), and noise levels (dBA). For a typical large-scale industrial seawater cooling tower, cooling capacities can range from several hundred to tens of thousands of tons, handling flow rates from 500 GPM to over 100,000 GPM. The fan motor power is a critical operational cost factor, with advanced designs focusing on high-efficiency motors and aerodynamic fan blades to minimize energy consumption. Noise levels are also increasingly important, particularly for facilities located near residential areas, necessitating noise reduction measures such as low-noise fans and acoustic attenuators. The heat transfer efficiency is significantly influenced by the fill media, which maximizes the contact surface area between air and water, promoting optimal evaporative cooling. Advanced designs often incorporate highly efficient PVC or PP fills specifically designed for high-salinity water, resisting biological fouling and scaling.

The performance of a seawater cooling tower is also heavily influenced by environmental factors. While designed for saline environments, extreme ambient temperatures and humidity levels can impact efficiency, requiring careful system sizing and selection. Our Circular Cooling Towers are engineered with a focus on maximizing thermal performance while minimizing environmental footprint. For instance, advanced drift eliminators are integrated to reduce water loss and prevent the carryover of saline droplets, which can cause environmental corrosion or damage to surrounding structures. This is particularly crucial for a water cooled cooling tower where minimizing water loss due to evaporation and drift is vital for sustainability. Furthermore, the towers incorporate efficient water distribution systems to ensure uniform wetting of the fill media, preventing dry spots that can reduce cooling efficiency and lead to scaling. The structural design takes into account wind loads, seismic activity, and the corrosive nature of the environment, ensuring long-term structural integrity. Below is a table outlining typical technical parameters for our seawater cooling tower models, illustrating the range and scalability of our solutions tailored to specific industrial demands. This data-driven approach allows clients to make informed decisions, ensuring the selected cooling tower aligns perfectly with their operational needs and sustainability goals.

Typical Seawater Cooling Tower Parameters

| Parameter | Unit | Typical Range (Circular Cooling Tower) |

|---|---|---|

| Cooling Capacity | TR / MW | 100 - 50,000 TR / 0.35 - 175 MW |

| Water Flow Rate | GPM / m³/h | 300 - 150,000 GPM / 70 - 34,000 m³/h |

| Hot Water Temperature (Inlet) | °C / °F | 35 - 55°C / 95 - 131°F |

| Cold Water Temperature (Outlet) | °C / °F | 25 - 40°C / 77 - 104°F |

| Wet-Bulb Temperature (Design) | °C / °F | 20 - 30°C / 68 - 86°F |

| Fan Motor Power | kW | 7.5 - 750 kW (per cell) |

| Noise Level (1m from source) | dBA | 65 - 85 dBA (standard) |

| Drift Loss | % of flow | Typically |

| Material (Main Structure) | FRP (Fiberglass Reinforced Plastic) |

Strategic Advantages and Customization Options

The deployment of a specialized seawater cooling tower confers significant strategic advantages for industries operating in coastal or water-scarce regions. Foremost among these is the dramatic reduction in reliance on freshwater sources, a critical environmental and economic benefit in a world facing increasing water stress. By utilizing readily available seawater, operations can achieve substantial savings on water acquisition, treatment, and discharge costs. Furthermore, the inherent corrosion resistance of FRP materials used in our Circular Cooling Towers translates into significantly lower maintenance expenditures and extended operational lifespans compared to traditional steel structures, which would rapidly degrade in a saline environment. This long-term durability ensures consistent performance and minimizes costly downtime for repairs or replacements. The efficiency of a seawater cooling tower also contributes directly to energy savings, as optimized heat rejection leads to lower condenser pressures and improved overall plant efficiency, particularly crucial for large-scale thermal power plant cooling tower applications. Beyond these core advantages, our commitment to customization allows us to tailor each seawater cooling tower solution to the specific demands of a client's process, site constraints, and environmental regulations.

Customization options for a seawater cooling tower range from structural modifications to accommodate limited footprints or specific aesthetic requirements, to performance enhancements like ultra-low drift eliminators for sensitive environments or specialized noise attenuation packages for urban areas. We can design towers with varying thermal loads, approach temperatures, and power consumption targets, ensuring optimal performance for distinct operational profiles. For example, some projects may prioritize minimal energy consumption, leading to larger fan diameters or more efficient fill media, while others might focus on compact designs. The flexibility in design extends to materials used for internal components, allowing for selection of specific grades of FRP or non-metallic components to handle highly aggressive water chemistry if needed beyond typical seawater. Every customization proposal is developed through close collaboration with the client's engineering teams, leveraging our extensive expertise in fluid dynamics, thermodynamics, and structural analysis to deliver a tailored, high-performing solution. This bespoke approach ensures that whether it's for a chemical plant requiring precise temperature control or a desalination facility needing robust, low-maintenance cooling, the final seawater cooling tower system is perfectly aligned with their operational objectives and delivers maximum value.

Industry Leadership and Application Case Studies

Our position as a leading manufacturer of seawater cooling tower solutions is cemented by decades of experience, rigorous adherence to international quality standards, and a proven track record of successful installations across diverse industries. We hold certifications such as ISO 9001 for quality management and ISO 14001 for environmental management, reflecting our commitment to both product excellence and sustainable practices. Our cooling towers have been deployed in critical infrastructure projects globally, including major thermal power plants, large-scale petrochemical complexes, integrated steel mills, and municipal desalination facilities. A prime example includes a recent project where our Circular Cooling Tower, designed as a true water cooling tower, was installed in a coastal power plant in Southeast Asia. This specific power plant required a cooling solution capable of rejecting 50,000 TR of heat while operating with highly saline intake water, minimizing drift loss to protect nearby sensitive ecological zones, and enduring category 5 hurricane-force winds. Our customized seawater cooling tower solution, featuring advanced FRP construction, high-efficiency drift eliminators with

Another notable application of our seawater cooling tower technology is in a large-scale chemical processing facility in the Middle East, where high ambient temperatures and aggressive chemical processes necessitated a robust and highly corrosion-resistant cooling solution. The client previously struggled with rapid degradation of metallic cooling tower components due to the combined effects of saline water and airborne chemical contaminants. By replacing their existing system with our specialized FRP seawater cooling tower, designed to function as a water cooled cooling tower, the client experienced a drastic reduction in maintenance costs, an improvement in cooling efficiency, and an extension of asset lifespan. This project underscored the superior resistance of FRP materials to both saline corrosion and chemical attack, demonstrating the versatility and resilience of our cooling tower designs. Our long service history, spanning over 20 years in the industry, coupled with strategic partnerships with engineering firms and contractors worldwide, underscores our authoritative presence and deep understanding of complex industrial cooling challenges. We pride ourselves on transparent communication, data-driven design, and post-installation support, fostering long-term trust and collaboration with our global clientele.

Competitive Landscape and Vendor Comparison

In the competitive landscape of industrial cooling solutions, distinguishing factors among manufacturers of seawater cooling tower systems often revolve around material science expertise, customization capabilities, energy efficiency, and post-sales support. While several vendors offer cooling tower solutions, few possess the specialized knowledge and proven track record in designing and manufacturing towers specifically for highly corrosive saline environments. Our company excels in this niche, leveraging advanced FRP composite technology and decades of experience to deliver superior lifespan and lower total cost of ownership compared to competitors who may primarily focus on fresh water applications or utilize less resistant materials. For instance, some manufacturers might use galvanized steel or less advanced FRP formulations, leading to compromised structural integrity or faster degradation when exposed to seawater's harsh conditions. Our commitment to using premium-grade, marine-specific FRP and non-metallic internal components ensures unparalleled resistance to corrosion, bio-fouling, and scaling, providing a distinct performance advantage over standard designs that might be adapted for saline use rather than purpose-built.

Beyond material superiority, our competitive edge in the seawater cooling tower market is also defined by our engineering prowess in optimizing thermal performance and energy consumption. We employ sophisticated computational fluid dynamics (CFD) and heat transfer modeling to design highly efficient fill media, fan blades, and water distribution systems that minimize power consumption while maximizing cooling capacity. This contrasts with some competitors who might offer off-the-shelf solutions with less optimized designs, leading to higher operational energy costs. Furthermore, our flexible manufacturing capabilities enable extensive customization, allowing us to meet highly specific client requirements, site constraints, and integrate seamlessly with existing plant infrastructure. This contrasts with vendors who might offer a limited range of standard models. Our global service network provides comprehensive support from initial consultation and design to installation supervision, commissioning, and long-term maintenance, ensuring continuous peak performance for every seawater cooling tower. The table below offers a high-level comparison to illustrate how our Circular Cooling Tower stands out against typical industry offerings for saline water applications, emphasizing key differentiators that translate into tangible benefits for our clients.

Seawater Cooling Tower Vendor Comparison

| Feature/Aspect | Our Circular Cooling Tower (Seawater Optimized) | Typical Competitor (Standard FRP/Steel) |

|---|---|---|

| Primary Structure Material | Marine-grade FRP (Purpose-built for Saline) | Standard FRP or Galvanized Steel (Adapted for Saline) |

| Corrosion Resistance | Excellent, virtually impervious to seawater | Good (FRP) to Moderate (Steel, requires frequent coating) |

| Typical Lifespan in Saline Env. | 25+ Years | 10-20 Years (FRP), 5-15 Years (Steel) |

| Energy Efficiency | Optimized through CFD/advanced designs (High) | Standard designs (Moderate to Good) |

| Customization Level | Extensive (Tailored to specific project needs) | Limited (Standard models with minor variations) |

| Drift Eliminator Efficiency | Ultra-low (Typically | Standard (Typically 0.001% - 0.005%) |

| Warranty & Support | Comprehensive (Longer terms, global network) | Standard (Shorter terms, regional focus) |

FAQs, Delivery, and Customer Support

Transparency and robust customer support are cornerstones of our service philosophy for every seawater cooling tower project. We understand that investing in such critical infrastructure requires clarity on all aspects, from initial inquiry to long-term operation. Our Frequently Asked Questions (FAQ) section addresses common concerns regarding the selection, installation, and maintenance of our Circular Cooling Towers. For example, a common question pertains to the expected lifespan of a seawater cooling tower in comparison to a traditional fresh water cooling tower, to which we confidently state that due to superior material selection and anti-corrosion design, our seawater units often surpass the longevity of standard towers even in their challenging environment. Another frequent inquiry is about the energy consumption, and we emphasize that while operational requirements vary by capacity, our designs are rigorously optimized for power efficiency, often leading to lower lifecycle costs than less specialized alternatives. We also provide clear guidance on water treatment requirements for saline systems, which while different from freshwater, are manageable with appropriate scaling and biofouling inhibitors specific to seawater.

Our commitment to customer satisfaction extends to our well-defined delivery and support processes. Upon finalization of the design and specifications for your seawater cooling tower, we provide a detailed project timeline, including manufacturing, quality assurance testing, packaging, and logistics. Typical manufacturing lead times for standard modules range from 10 to 14 weeks, with customized or large-scale projects requiring between 16 to 24 weeks. We prioritize efficient and secure packaging to protect all components during transit, utilizing specialized crating and shipping container111s to ensure damage-free arrival at your site. Our global logistics team manages customs clearance and delivery to even remote locations. Furthermore, our comprehensive warranty program provides peace of mind, covering structural integrity and performance for a stipulated period, typically ranging from 1 to 5 years depending on specific components, demonstrating our confidence in the durability and reliability of our seawater cooling tower solutions. Post-installation, our dedicated technical support team offers remote assistance, on-site troubleshooting, and periodic maintenance guidance to ensure your cooling tower operates at peak efficiency throughout its long service life, reinforcing our role as a trusted partner in your industrial operations.

References

- Cooling Technology Institute (CTI) Standards and Publications, specifically those addressing materials and performance for cooling towers in corrosive environments.

- American Society of Mechanical Engineers (ASME) standards for pressure vessels and heat exchangers, relevant to cooling system design principles.

- International Organization for Standardization (ISO) 9001 and ISO 14001 guidelines for quality and environmental management systems in manufacturing.

- NACE International (formerly National Association of Corrosion Engineers) publications on corrosion control and prevention in marine and industrial settings.

- Academic research papers on advanced composite materials and their application in harsh industrial environments, particularly saline water.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China