We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

- Introduction: The Evolution and Demand for FRP Water Storage Solutions

- Technical Edge: Advantages of FRP Materials in Fluid Management

- Comparative Analysis: Reviewing FRP Water Tank, Pipe, and Grating Suppliers

- Customization: Tailored FRP Water Tank Solutions for Diverse Needs

- Application Insights: Real-World Implementations and Industry Use Cases

- Quality Measures: Standards, Certifications, and Sustainability Factors

- Conclusion: Why Leading Industries Rely on FRP Water Tank Suppliers

(frp water tank suppliers)

Introduction: The Rise and Impact of FRP Water Tank Suppliers

Over the past decade, the water management sector has witnessed a transformative shift in storage and conveyance solutions. Fiber Reinforced Plastic (FRP) water tanks now dominate segments traditionally served by steel or concrete, primarily due to their exceptional strength-to-weight ratio, longevity, and corrosion resistance. According to industry analytics, the global FRP tank market achieved a valuation of USD 1.9 billion in 2023, reflecting an anticipated compound annual growth rate (CAGR) of 6.2% through 2030. This increasing demand correlates with heightened regulatory requirements for clean water storage, space efficiency, and ease of installation, creating critical opportunities for FRP water tank suppliers as well as complementary sectors like FRP pipe suppliers and FRP grating suppliers. As infrastructure ages and industrial needs evolve, identifying reliable FRP solutions providers has become an integral decision for project managers and engineers worldwide.

Technical Advantages: Why FRP Outperforms Traditional Materials

The selection of FRP (Fiber Reinforced Plastic) in water storage and fluid handling projects is underpinned by robust technical benefits. Primarily, FRP panels and laminates offer a tensile strength surpassing that of standard carbon steel while remaining 70% lighter, according to material science journals. FRP is non-corrosive and unaffected by the majority of chemical agents, which drastically reduces maintenance intervals and life-cycle costs. The thermal insulation properties intrinsic to FRP mitigate external temperature fluctuations—key for potable water and sensitive process fluids. Additionally, modular FRP tanks and gratings are prefabricated for rapid onsite installation, reducing project timelines by up to 30% compared to legacy options. UV resistance, adaptability to seismic designs, and compatibility with integrated instrumentation further distinguish FRP water tank suppliers and associated components. These factors collectively make FRP the preferred material in highly regulated industries where reliability, efficiency, and hygiene are paramount.

Supplier Comparison: Industry-Leading FRP Water Tank, Pipe, and Grating Providers

Selecting a supplier is a critical juncture for project success. Below is a comparative table summarizing key metrics of renowned FRP suppliers, allowing stakeholders to benchmark performance, offerings, and compliance:

| Supplier | Main Products | Annual Capacity (m3 / tons) | Lead Time | Certifications | Export Markets |

|---|---|---|---|---|---|

| AquaSafe Composites | FRP Water Tanks, Pipes, Gratings | 12,000 m3 / 3,500 tons | 20–35 days | ISO 9001, NSF/ANSI 61 | North America, EU |

| EnviroTech Fiberglass | FRP Water Tanks, GRP Pipes | 10,500 m3 / 2,800 tons | 30–45 days | ISO 14001, WRAS | MENA, Asia-Pacific |

| ProFiber Solutions | FRP Gratings, Pipes | 6,800 m3 / 1,700 tons | 14–25 days | ISO 9001, SGS | Europe, Southeast Asia |

| PolyGlass Engineers | FRP Tanks, Molded Gratings | 8,200 m3 / 2,100 tons | 18–30 days | ISO 45001, BIS | India, GCC |

The data reveals that leading FRP water tank suppliers are differentiated by rapid production capacity, global certification, and tailored product portfolios. When evaluating suppliers, key considerations must include not only speed and scale but also post-sale technical support, documentation, and track record in meeting unique site challenges.

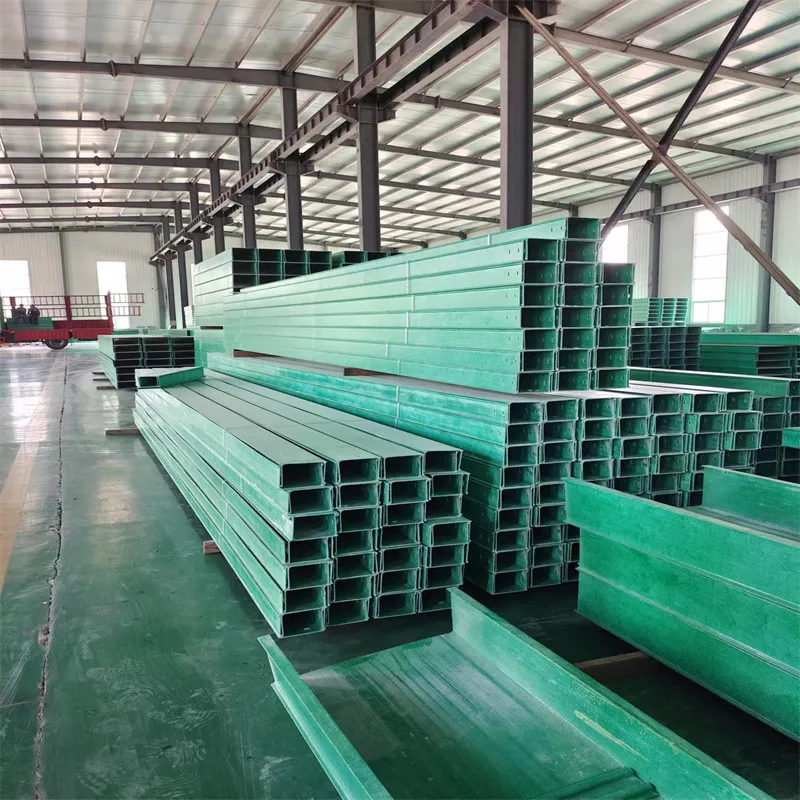

Customization: Engineering Optimized FRP Water Tank Solutions

No two water management projects are identical; thus, customization is a core service from premium FRP water tank suppliers. Companies leverage advanced 3D modeling and finite element analysis (FEA) tools to engineer tanks that suit client-specific volume, pressure, and spatial constraints. Common variants include sectional panel tanks for rooftop applications, cylindrical tanks for high-pressure industrial setups, and underground tanks for municipal water storage. Wall thickness, liner type, support configurations, and access modules can all be fine-tuned. For instance, in food-grade installations, enhanced gelcoats and FDA-compliant resins are specified. Leading manufacturers offer integration with remote monitoring systems, anti-bacterial linings, and modular expansion features to future-proof investments. This approach provides scalability while ensuring full alignment with regional building codes and project delivery targets.

Industry Applications: Success Stories and Field Deployments

FRP water tanks, pipes, and gratings found in projects globally demonstrate the material’s striking versatility and performance. In 2022, a major petrochemical complex in Singapore selected an FRP water tank system with a total capacity of 3,750 m3, reporting a 27% decrease in maintenance expenditures over 24 months compared to the previous steel solution. Municipal utilities in the United Kingdom have standardized FRP panel tanks for potable water, citing durability, ease of installation in confined spaces, and reduced risk of leaks. In the mining sector, high-strength FRP pipes and gratings withstand aggressive chemicals and abrasive slurries, contributing to uninterrupted operation even under continuous load. Educational campuses, commercial high-rises, and emergency relief infrastructure all benefit from the modularity and hygiene FRP affords. These field-proven cases underscore the role of innovative FRP pipe suppliers and FRP grating suppliers in shaping resilient, future-ready systems.

Quality Assurance: Standards and Sustainable Practices

Achieving and maintaining quality is non-negotiable for projects governed by strict regulatory oversight. Premium FRP water tank suppliers operate under international standards such as ISO 9001 (Quality Management) and ISO 14001 (Environmental Management). Third-party certifications like NSF/ANSI 61 for drinking water applications, or WRAS approval, are often prerequisites for public infrastructure bids. Sustainability efforts are increasingly prominent, with suppliers adopting recyclable resins, optimizing production to minimize VOC emissions, and deploying life-cycle assessment (LCA) methodologies. A 2023 market survey cited that 73% of municipal water projects prioritize suppliers with published Environmental Product Declarations (EPDs) and stringent quality control. Lifecycle warranties up to 30 years and comprehensive documentation support specification, inspection, and ease of future upgrades—guaranteeing long-term value and compliance.

Conclusion: The Strategic Value of Partnering with Top FRP Water Tank Suppliers

In summary, industries seeking safe, efficient, and sustainable water storage solutions continually return to proven FRP water tank suppliers for their projects. The integration of technical superiority, competitive supplier landscape, and project-specific customization ensures that these solutions remain at the forefront of modern infrastructure development. Stringent quality controls and certified manufacturing standards support reliability, while innovative applications across public works, industry, and emergency management testify to the adaptability of FRP tanks, pipes, and gratings. As global water demands intensify and infrastructure modernization accelerates, collaboration with experienced FRP providers is crucial for enduring project success and regulatory assurance.

(frp water tank suppliers)

FAQS on frp water tank suppliers

Q: What should I consider when choosing FRP water tank suppliers?

A: Look for suppliers with proven quality certifications, reliable after-sales service, and customization options for different capacities. It is also important to check for competitive pricing and timely delivery. Ask for references or case studies before making your decision.Q: Do FRP water tank suppliers often provide installation services?

A: Many FRP water tank suppliers offer professional installation services for their products. This ensures proper fitting and longer tank lifespan. Always confirm with your supplier if installation is included in their quotation.Q: Can FRP pipe suppliers provide custom pipe diameters and lengths?

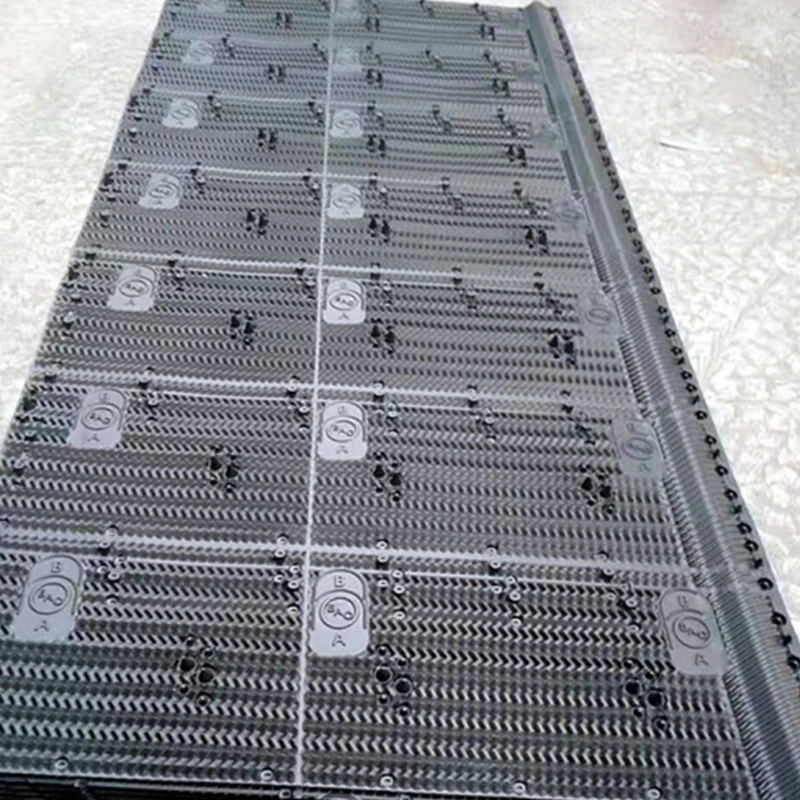

A: Yes, reputable FRP pipe suppliers typically offer customized sizes according to specific project requirements. This includes different diameters, lengths, and thicknesses. Be sure to communicate your exact needs during the inquiry process.Q: What are the advantages of purchasing from specialized FRP grating suppliers?

A: Specialized FRP grating suppliers provide products with enhanced strength, corrosion resistance, and tailored dimensions. They also offer advice on the best grating type for your application. Their expertise ensures product durability and safety.Q: Are there suppliers who can offer FRP water tanks, pipes, and grating together?

A: Yes, some comprehensive FRP suppliers manufacture and supply water tanks, pipes, and grating as a package. This streamlines purchasing and may offer bundled discounts. Always ask if combined supply options are available.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China