We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Production Line Configurations

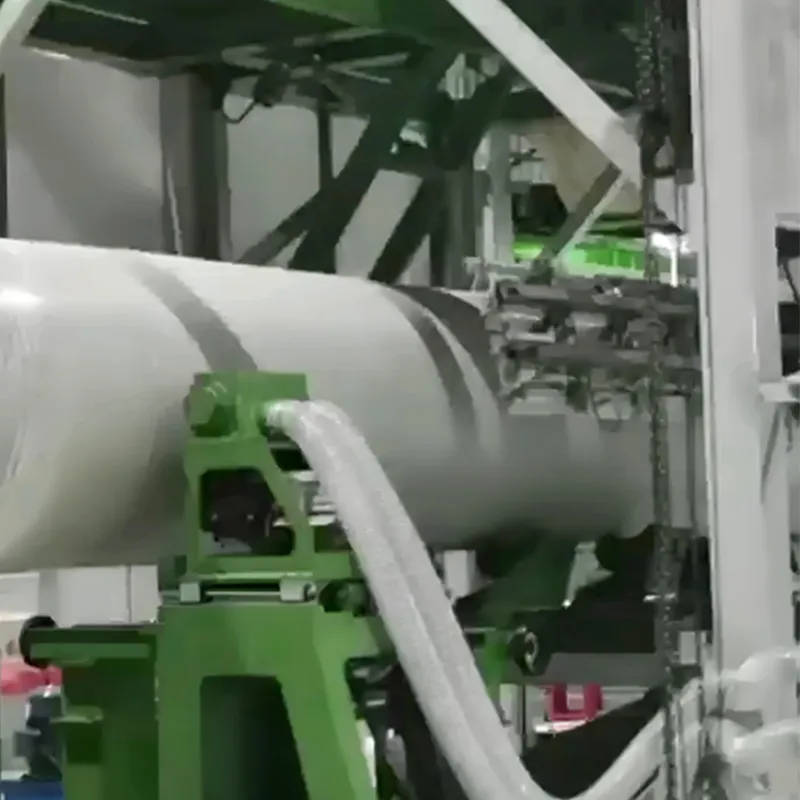

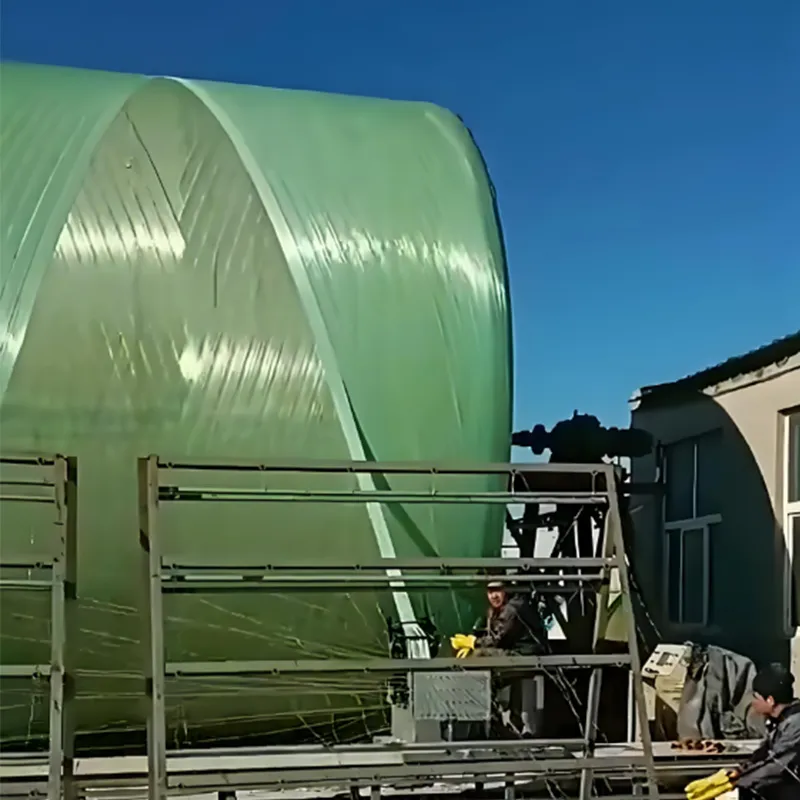

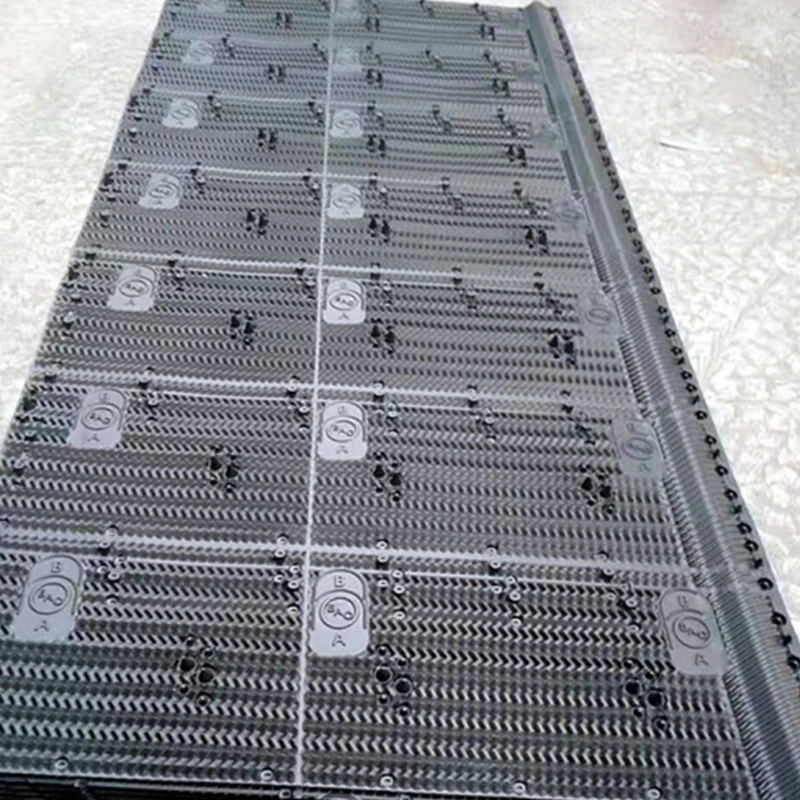

1. Filament Winding Line (CW)

Winding Patterns: Helical/circumferential/planar (0°-90° adjustable)

Mandrel System: 6-24m steel mandrels with temperature control (RT-150°C)

Resin Application: Computer-controlled dip bath or direct injection

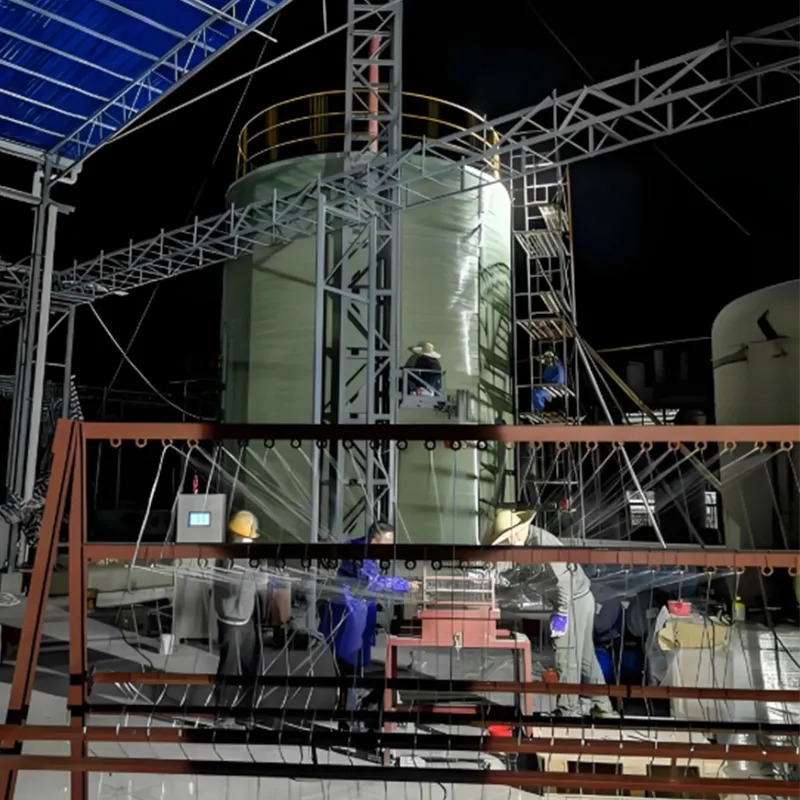

2. Centrifugal Casting Line (CC)

Rotational Speed: 200-1,200 RPM (variable frequency control)

Curing System: IR pre-curing + microwave final curing

Liner Options: C-glass veil or PVDF film for enhanced corrosion barrier

Technical Specifications

|

Parameter |

Filament Winding Line |

Centrifugal Casting Line |

|

Pipe Diameter |

100-3,000mm |

50-4,000mm |

|

Wall Thickness |

3-50mm |

5-100mm |

|

Production Speed |

0.3-2m/min |

0.5-3m/hour |

|

Pressure Rating |

PN6-PN25 |

PN10-PN40 |

|

Stiffness |

5,000-25,000 N/m² |

10,000-50,000 N/m² |

Key Technological Advantages

✔ Multi-Axis Winding: 6-axis CNC control for complex layup (±0.1° accuracy)

✔ Smart Resin Management: Viscosity-controlled dosing with ≤2% variation

✔ Quality Assurance:

Online ultrasonic thickness monitoring

Automated holiday detection (9kV/mm)

Material Performance Comparison

|

Property |

FRP Pipe |

Steel Pipe |

HDPE Pipe |

|

Corrosion Resistance |

Excellent (pH 0-14) |

Requires lining |

Limited (pH 2-12) |

|

Weight |

1/4 of steel |

Heavy |

Lightweight |

|

Life Cycle Cost |

60% lower over 20 years |

High maintenance |

Moderate |

|

Thermal Conductivity |

0.3 W/mK |

45 W/mK |

0.4 W/mK |

Automation Features

Mandrel Handling: Automated loading/unloading with 10-ton capacity

Cutting System: Diamond-tipped saw (±0.5mm length tolerance)

IoT Integration: Predictive maintenance for resin pumps and mandrel bearings

Certifications: ASME RTP-1, ISO 14692, AWWA C950

Industry Applications

◼ Chemical Processing: HCl/H2SO4 transport (0.5mm corrosion liner)

◼ Oil & Gas: Produced water lines (API 15HR compliant)

◼ Desalination: Seawater intake pipes (anti-biofouling additives)

◼ Power Plants: FGD scrubber ducts (180°C continuous service)

Lead Time: 120 days for standard lines, 150-180 days for dual-process systems

What Our Customers Say About Us

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China