We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

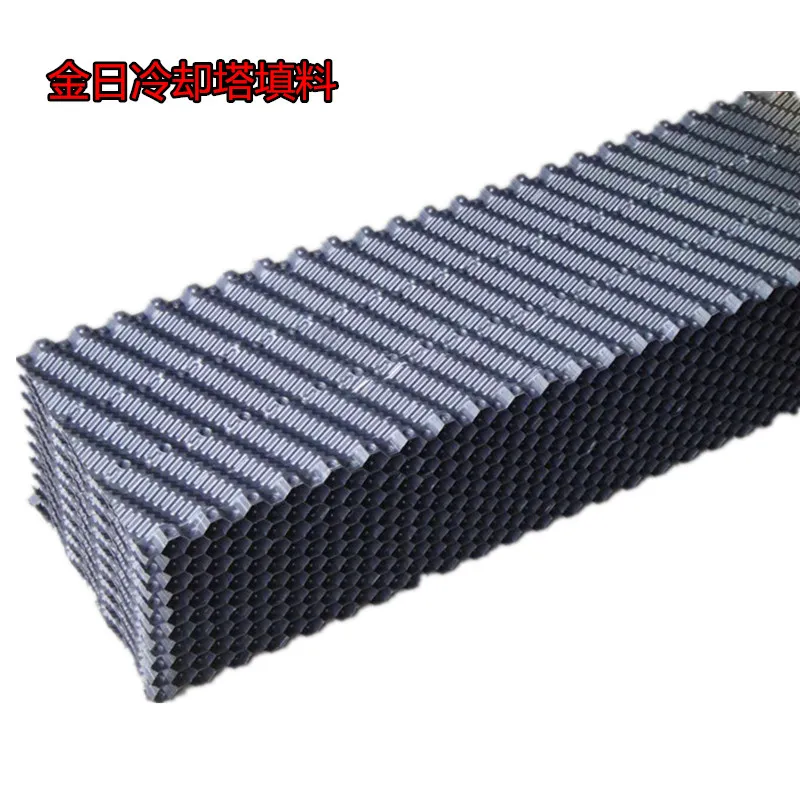

Advantages of Cooling Tower Fill (English Version)

1.High Cooling Efficiency

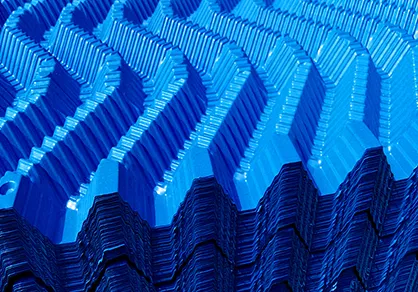

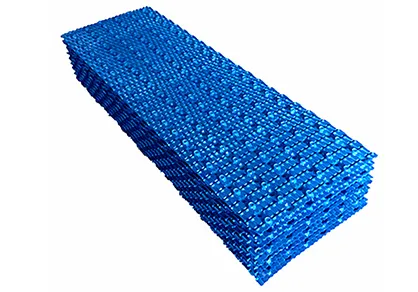

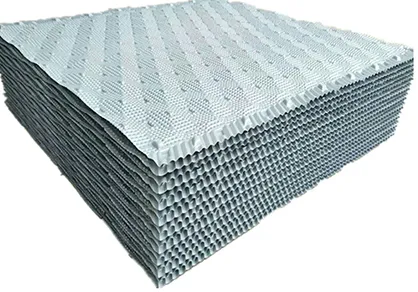

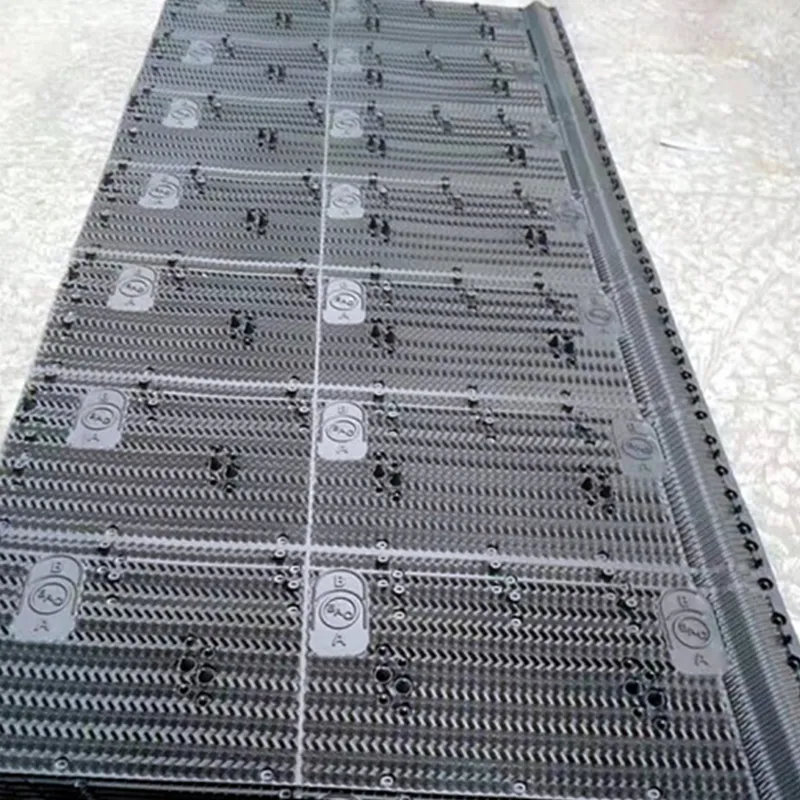

Enhanced Heat Transfer: Cooling tower fill increases the surface area for air-water contact, achieving mass transfer coefficients up to 0.035 kg/(m²·s) in film fills (e.g., S-wave designs), which is 40% higher than splash fills.

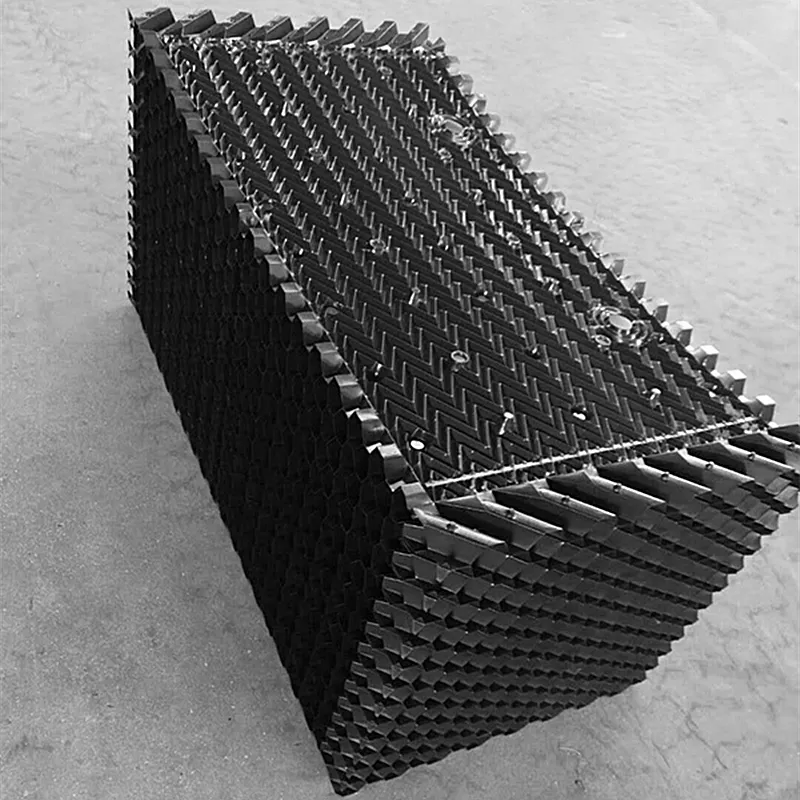

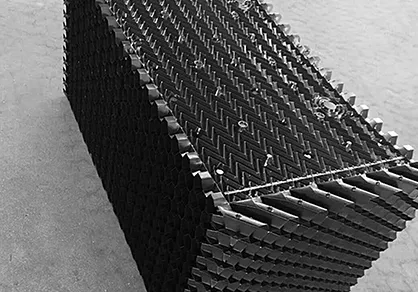

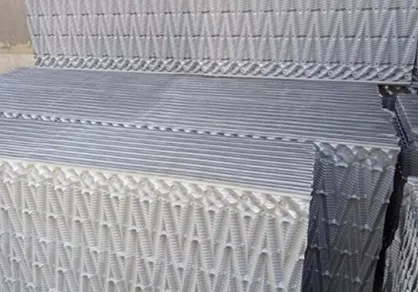

- Optimized Flow Design: Corrugated patterns (e.g., cross-fluted or herringbone fills) reduce air resistance by 15-30%, improving thermal exchange while minimizing energy loss.

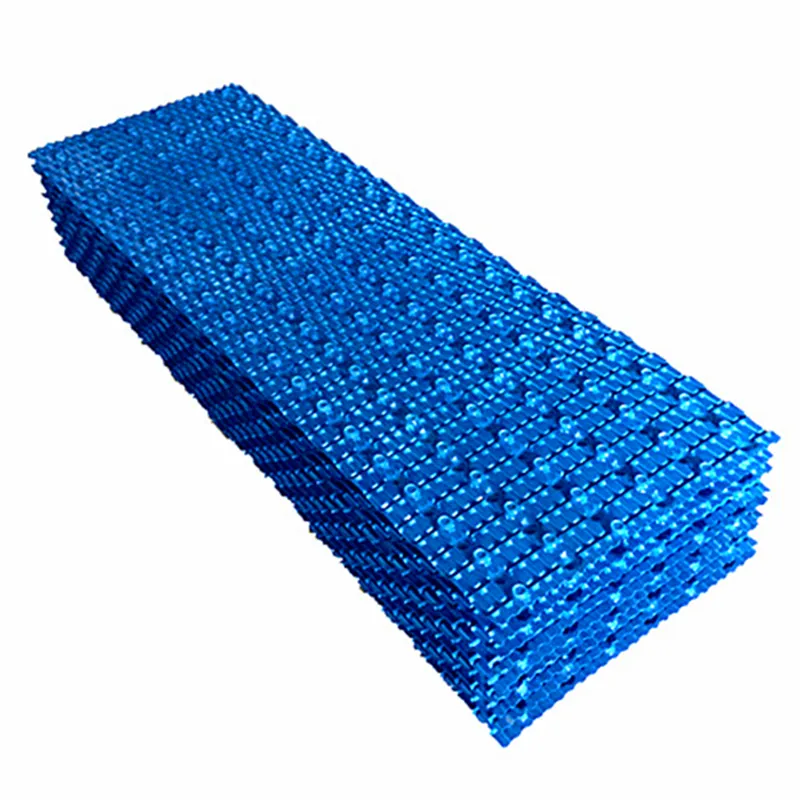

2. Durability & Corrosion Resistance

- Material Longevity:

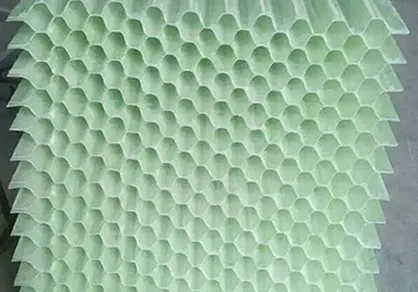

- PVC/PP Fills: UV-resistant and chemically stable, with a lifespan of 10-15 years under harsh conditions (e.g., pH 0-14).

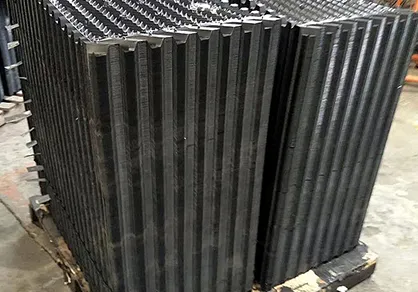

- Ceramic Fills: Withstand temperatures up to 300°C and resist scaling, ideal for high-temperature industrial applications (e.g., power plants).

- Structural Integrity: Hot-dip galvanized or FRP-reinforced fills prevent deformation under heavy loads (≥3,000 N/m²).

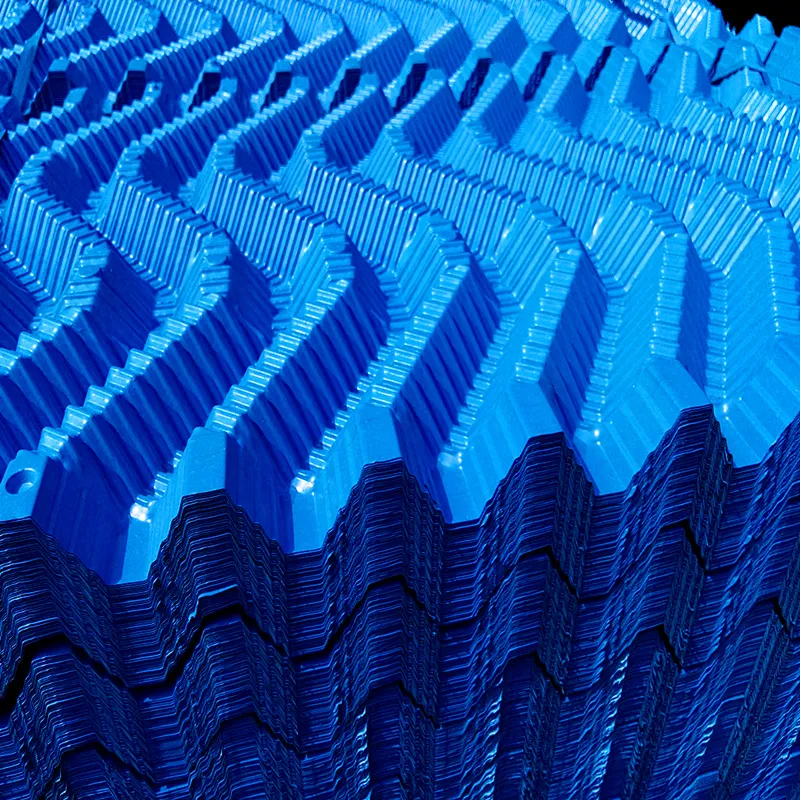

3. Energy & Water Savings

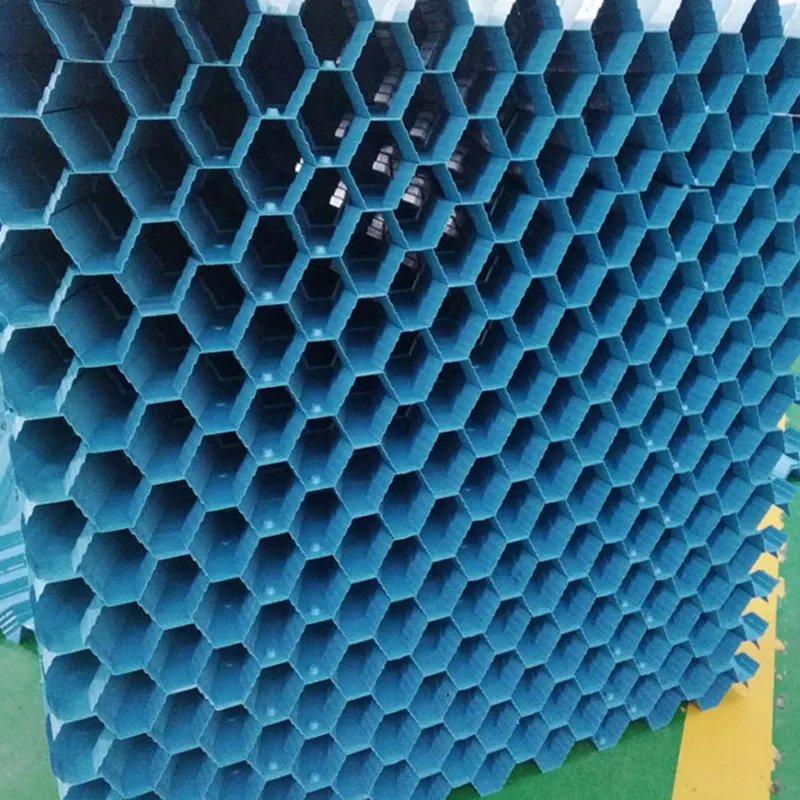

- Reduced Pump Energy: Large-surface designs (e.g., hexagonal honeycomb fills) lower hydraulic resistance, cutting pump energy consumption by 15%.

- Water Conservation: Closed-loop systems with anti-evaporation designs reduce water loss by 30%, aligning with ISO 14001 standards.

4. Low Maintenance & Modular Flexibility

- Anti-Clogging Design: Stepped trapezoidal or offset fluted fills minimize debris accumulation, reducing cleaning frequency by 30%.

- Modular Assembly: Replaceable fill blocks allow partial repairs without system shutdown, ensuring 99% uptime in critical industries (e.g., data centers).

5. Versatile Application Compatibility

- Industrial Scenarios:

- Chemicals/Power Plants: Ceramic fills handle acidic gases (pH 0-14) and high-temperature exhaust.

- Data Centers: PP fills paired with closed-loop towers reduce PUE to 1.3.

- HVAC Systems: S-wave fills in commercial cooling towers achieve drift loss as low as 0.001%.

6. Environmental Compliance

- Eco-Friendly Materials: Flame-retardant PVC (oxygen index ≥30) and recyclable PP reduce carbon footprint.

- Noise Control: Low-noise axial fans (≤65 dB) and optimized airflow paths meet urban noise regulations.

Key References:

- Material & Efficiency:

- Durability:

- Energy Savings:

- Maintenance:

- Applications:

For detailed specifications or custom solutions, consult manufacturers for fill material compatibility and thermal performance curves.

What Our Customers Say About Us

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China