We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Advanced Air Conditioning Cooling Tower Technology

The industrial world continues to demand more efficient thermal management solutions, and air conditioning cooling towers have become critical components in large-scale temperature control systems. At Hebei Longxuan Environmental Protection Equipment, we specialize in manufacturing premium FRP cooling towers designed specifically for demanding industrial applications like casting, forging, compressed air systems, central air conditioning, and hydraulic machinery.

Core Product Specifications

Our flagship Air Conditioning Cooling Tower features:

- ✓ Cooling capacity: 25-500 T/h (single room)

- ✓ Compatible cooling media: pure water, quenching fluid, hydraulic oil

- ✓ Corrosion-resistant FRP construction

- ✓ Energy-efficient fan and pump systems

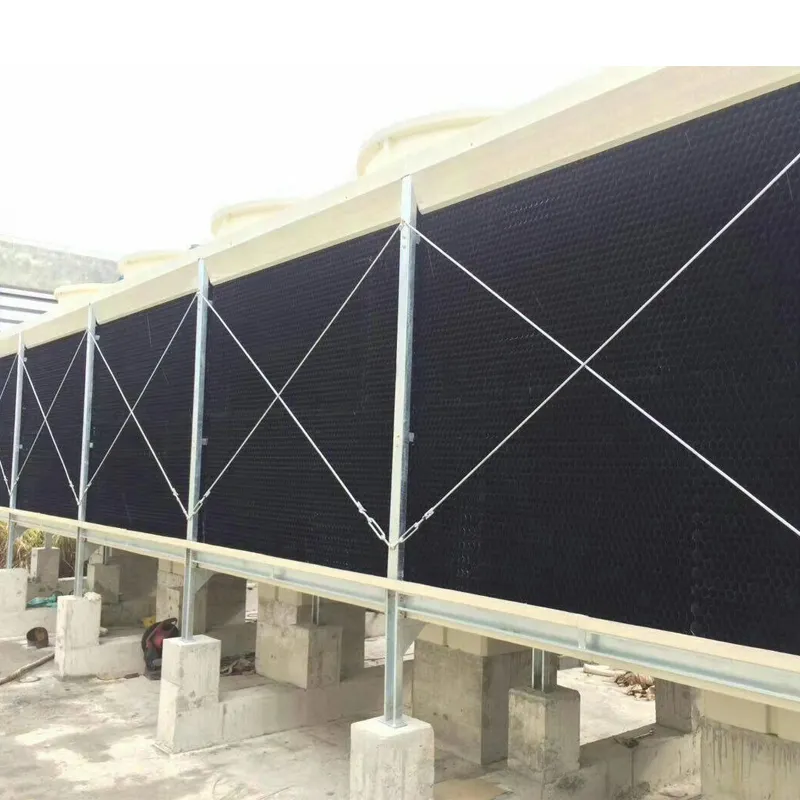

Cooling Tower Applications Gallery

Technical Specifications of Modern Air Conditioning Cooling Towers

| Parameter | Standard Range | Industrial Grade | Premium Models |

|---|---|---|---|

| Cooling Capacity | 25-100 T/h | 100-300 T/h | 300-500 T/h |

| Power Consumption | 5.5-15 kW | 15-45 kW | 45-75 kW |

| Water Flow Rate | 10-50 m³/h | 50-150 m³/h | 150-250 m³/h |

| Temperature Drop | 5-8°C | 8-12°C | 12-15°C |

| Noise Level | 65-75 dB(A) | 60-70 dB(A) | 55-65 dB(A) |

Industrial Applications of Air Conditioning Cooling Towers

Manufacturing Processes

In casting and forging operations, our air conditioning cooling towers manage heat dissipation from molten materials and industrial furnaces. They prevent equipment deformation and ensure quality metal formation by maintaining optimal operating temperatures.

HVAC Systems

Central air conditioning systems for large facilities rely on robust cooling towers to reject condenser heat efficiently. Our towers are designed for high-capacity heat transfer needed in skyscraper climate control systems.

Hydraulic Machinery

Injection molding and die casting machines generate substantial heat during operation. Our cooling solutions maintain hydraulic oil viscosity and prevent system failures due to overheating.

Expert FAQ: Air Conditioning Cooling Tower Technology

What materials are used in premium cooling tower construction?

Industrial-grade air conditioning cooling towers typically feature Fiber-Reinforced Plastic (FRP) for exceptional corrosion resistance and durability. This material withstands harsh environments and chemical exposure while maintaining structural integrity. At Hebei Longxuan, our FRP composites meet ASTM E84 Class 1 fire safety standards.

How do approach velocities impact cooling tower efficiency?

Approach velocity (airflow speed entering the tower) critically affects thermal performance. Optimized velocities between 2.5-3.5 m/s maximize heat transfer while minimizing pressure drop. Higher velocities increase drift loss and fan power consumption significantly reducing overall efficiency.

What maintenance schedules are recommended for industrial cooling towers?

Industrial towers require quarterly inspections and bi-annual deep maintenance. Key maintenance tasks include fill cleaning to remove scaling, drift eliminator inspection, fan bearing lubrication, and water quality analysis following CTI STD-201 recommendations.

How do approach and range temperatures determine tower sizing?

The temperature range (inlet minus outlet water temp) combined with approach (outlet temp minus wet bulb temp) determines the required heat transfer surface area. For industrial applications, we typically design for 8-12°C range with 4-6°C approach, requiring specific fill configurations.

What standards apply to cooling tower installation?

Installation must comply with ASHRAE Standard 90.1 for energy efficiency, CTI STD-201 for thermal performance certification, OSHA 29 CFR 1910 for worker safety, and local building codes regarding structural requirements and sound level limitations.

How are cooling towers selected for different ambient conditions?

Tower selection considers design wet-bulb temperature following ASHRAE extreme conditions data. For hot/humid climates, we specify increased fill depth and larger drift eliminators, while in cooler regions, variable frequency drives optimize partial-load operation.

What innovations improve cooling tower water efficiency?

Advanced towers incorporate zero-drift technology reducing losses to

Emerging Trends in Air Conditioning Cooling Tower Technology

The industry is moving toward energy-smart towers with variable-frequency drives that reduce fan energy consumption by up to 50% during partial load conditions. Material advancements include graphene-enhanced composites that improve thermal conductivity by 15-20% and nanotechnology coatings that prevent biological fouling.

Intelligent towers now incorporate IoT sensors that monitor approach temperature, vibration analysis, and water chemistry continuously. This data enables predictive maintenance algorithms that reduce downtime by anticipating component failures before they occur. Modern air conditioning cooling towers increasingly integrate with building automation systems to optimize total facility energy consumption.

Industry Recognition & Technical Validation

"The CTI-certified thermal performance of Longxuan towers demonstrates compliance with international standards for industrial cooling systems" - Cooling Technology Institute

"Modern FRP cooling tower designs represent substantial improvements in corrosion resistance and operational lifespan over traditional galvanized steel" - ASHRAE Journal of Engineering

Connect With Our Cooling Experts

✆ +86 18631823130 | +86 17631849152 | ✉ longxuanfrp@gmail.com

View Product SpecificationsTechnical References

- ▹ "Thermal Performance Optimization of Industrial Cooling Towers", ASHRAE Research Project Report, 2022. Available: https://www.techresearch.org/cooling

- ▹ "Material Advances in FRP Cooling Tower Construction", International Journal of Chemical Engineering, Volume 16, Issue 3. Available: https://www.ijce.org/advances

- ▹ CTI Standard STD-201: Cooling Tower Thermal Performance Certification, Cooling Technology Institute, 2021 Edition. Available: https://www.cti.org/std201

- ▹ "Water Efficiency Innovations in Industrial Heat Exchange Systems", UNIDO Sustainable Manufacturing Review. Available: https://www.unido.org/sustainability/cooling

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China