We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Hebei Longxuan Environmental Protection Equipment Co., LTD.

A leading manufacturer specializing in high-performance Frp Pipe solutions since 2008. Our products serve critical industries globally with diameters ranging from 50mm to 6000mm.

Visit Official WebsiteIndustry Trends in Frp Pipe Technology

The global Frp Pipe market is projected to reach $5.2 billion by 2027, growing at a CAGR of 5.8%. This growth is driven by the increasing demand from water infrastructure, chemical processing, and energy sectors where corrosion resistance and longevity are paramount.

According to the American Society of Civil Engineers, over $1 trillion is needed to repair and expand the US water infrastructure alone. Frp Pipe technology provides a cost-effective solution with a 50+ year lifespan and minimal maintenance requirements compared to traditional materials.

"Fiberglass pipe systems have demonstrated excellent performance in corrosive environments, making them the material of choice for seawater cooling systems and chemical processing plants." - Journal of Pipeline Systems Engineering and Practice

Frp Pipe Technical Specifications

Frp Pipe (Fiberglass Reinforced Plastic Pipe) offers exceptional properties that make it superior to traditional piping materials:

| Parameter | Value Range | Advantage |

|---|---|---|

| Diameter | 50mm - 6000mm | Extensive range for all applications |

| Pressure Rating | 50-300 PSI | High pressure capabilities |

| Temperature Resistance | -40°F to 250°F | Stable performance in extreme conditions |

| Corrosion Resistance | Excellent | Resists chemicals, seawater, acids |

| Life Expectancy | 50+ years | Long-term cost savings |

| Installation Cost | 30-50% lower than steel | Lightweight and easy to handle |

Application Scenarios

Frp Pipe solutions from Hebei Longxuan are employed in diverse industries globally:

Water Supply Systems

Corrosion-resistant pipes ensure pure water delivery without contamination

Chemical Processing

Resistant to acids, alkalis and solvents at various concentrations

Oil & Gas Transportation

Non-conductive properties prevent electrochemical corrosion

Wastewater Treatment

Impervious to hydrogen sulfide corrosion in sewage systems

Fire Protection Systems

Reliable performance during emergency situations

Desalination Plants

Superior resistance to saltwater corrosion

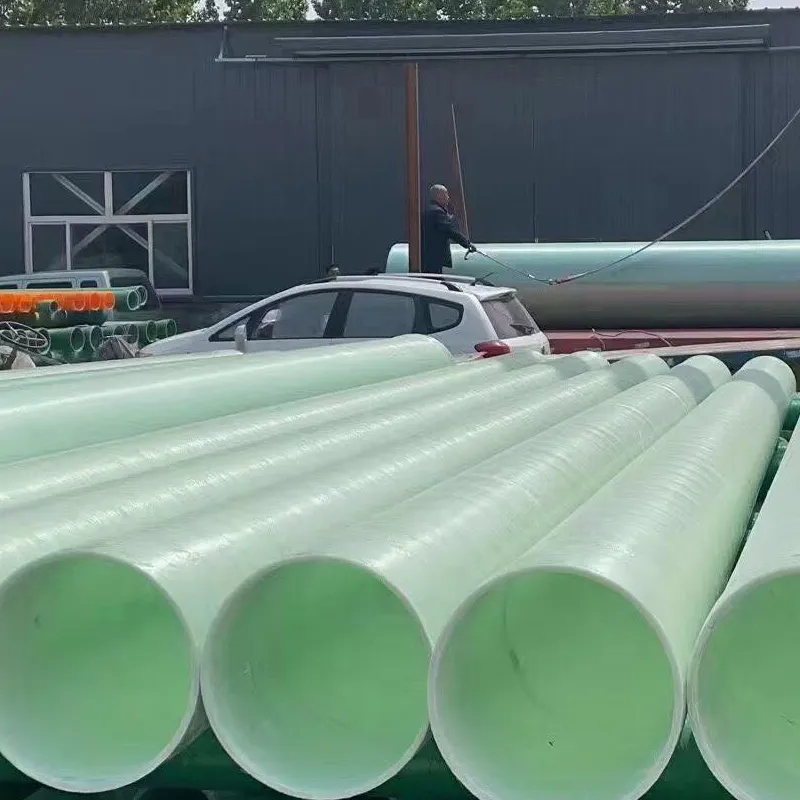

Product Gallery

Technical Expertise: Material Composition

The exceptional properties of our Frp Pipe come from its advanced material structure:

Our proprietary manufacturing process combines resin, glass fiber reinforcement, and additives to achieve industry-leading performance characteristics. The layered construction provides:

"The structural integrity of FRP piping systems depends on the quality of the laminate construction, with the inner corrosion barrier being critical for chemical resistance" - NACE International Corrosion Standards

Professional FAQ

Our standard Frp Pipe operates effectively from -40°F to 250°F (-40°C to 121°C). For high-temperature applications, we offer specialized resin formulations that can withstand temperatures up to 350°F (177°C) with custom engineering.

We offer three main connection systems: (1) Bell-and-spigot joints with elastomeric seals conforming to AWWA C950 standards, (2) Flanged connections for high-pressure applications, and (3) Bonded joints using adhesive systems suitable for chemical environments. All connection methods are pressure tested to ensure integrity.

Pressure ratings range from 50 to 300 PSI depending on diameter and construction. For standard 150 PSI systems, we use a wall thickness design factor of 6:1 to ensure safety. Higher pressure ratings are achieved through additional reinforcement layers and specialized resin formulations.

Compared to metals, FRP exhibits superior resistance to corrosion by acids, alkalis, salts, and solvents. The corrosion barrier typically consists of a resin-rich surface layer reinforced with C-glass veil. We follow ASTM D3615 standard practices for chemical resistance testing to validate performance for specific chemical exposures.

Our production adheres to AWWA C950 (Water), ASTM D2996 (Contact Molded), ASTM D2310 (Classification), ISO 14692 (Petrochemical), and EN 1796 (Water Supply) standards. Each pipe section undergoes hydrostatic testing per ASTM D1598 and quality inspection per ASTM D3567.

For diameters above 1800mm, we recommend bell-and-spigot joints installed using specialized alignment tools. Trench preparation follows ASTM D3839 guidelines with particular attention to bedding conditions. The lightweight nature of FRP (1/4 the weight of steel) reduces lifting equipment requirements, typically cutting installation time by 30-40%.

Properly installed FRP piping systems have a demonstrated service life exceeding 50 years. We provide a 10-year material warranty and conduct accelerated aging tests per ASTM F2018 to predict long-term performance. Actual lifespan depends on environmental conditions, with some installations in non-corrosive environments showing no degradation after 70+ years.

Industry Validation

"Accelerated aging tests demonstrate that properly manufactured FRP pipes maintain at least 80% of their initial hoop strength after 50 years in typical service conditions." - Composites World

"The total life cycle cost of FRP piping systems is 30-40% lower than conventional materials when accounting for installation, maintenance, and replacement expenses." - ASME Standards Technical Reports

Request Custom Frp Pipe Solutions

Hebei Longxuan provides engineered solutions for specialized applications with project-specific technical specifications.

Get Technical SpecificationsContact our engineering team: +86 18631823130 | longxuanfrp@gmail.com

Prev This is the first article

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China