We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

- Critical role and components of closed cooling water systems

- Data-driven impact on power plant operations

- Technical advantages of modern cooling systems

- Comparative analysis of leading manufacturers

- Customized engineering solutions for diverse plants

- Performance validation through application case studies

- Maintaining optimal performance in cooling infrastructure

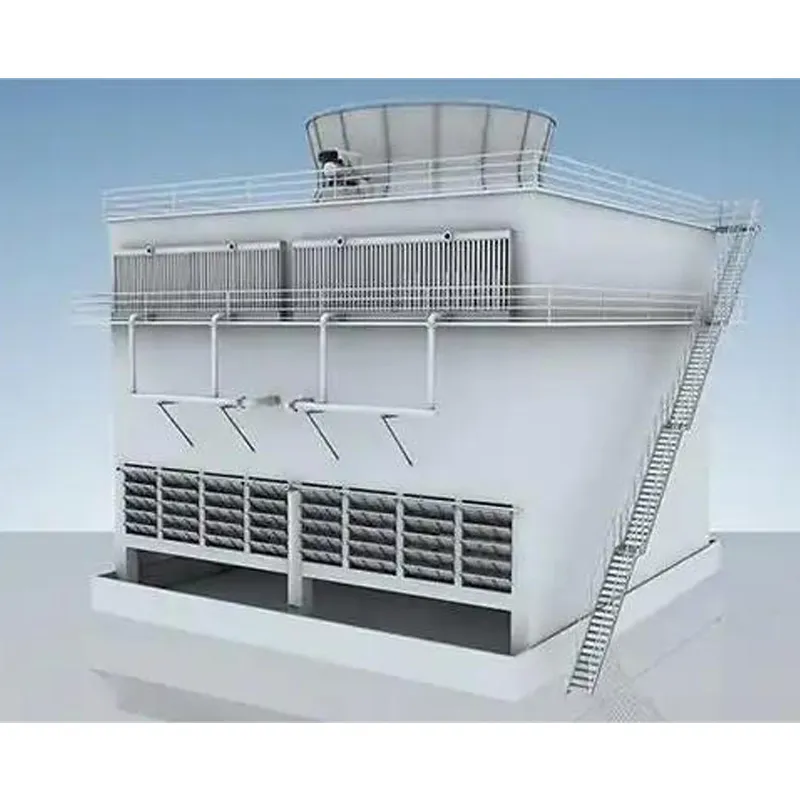

(closed cooling water system in power plant)

The Vital Role of Closed Cooling Water Systems in Power Generation

Closed cooling water (CCW) systems serve as the circulatory network for thermal power plants, continuously regulating temperatures for critical equipment. These sealed loops prevent scaling and contamination by maintaining chemically treated water separate from external sources. Principal components include plate heat exchangers, centrifugal pumps with redundant configurations, corrosion-resistant piping networks, and advanced control valves. Cooling towers complement these systems by dissipating excess heat through either natural draft hyperbolic designs or mechanical draft configurations. The integration of CCW systems with cooling towers constitutes an energy recovery ecosystem where waste heat from steam condensers is repurposed for auxiliary processes. Design variations accommodate site-specific factors including ambient conditions, water availability, and spatial constraints, with contemporary installations increasingly prioritizing water conservation through zero-liquid-discharge configurations.

Operational Impact Metrics of Optimized Cooling Systems

Data analysis reveals quantifiable benefits when upgrading cooling infrastructure. Power facilities implementing advanced CCW systems report significant performance improvements:

| Performance Indicator | Legacy Systems | Optimized CCW Systems | Improvement |

|---|---|---|---|

| Water Consumption | 1.8 m³/MWh | 0.45 m³/MWh | 75% reduction |

| Heat Rate Efficiency | 10,450 kJ/kWh | 9,850 kJ/kWh | 5.7% improvement |

| Maintenance Frequency | Bi-monthly shutdowns | Annual inspections | 83% reduction |

| Component Lifespan | 7-10 years | 15+ years | 50%+ extension |

These metrics translate to tangible financial returns, with 600MW plants achieving $2.1M annual savings through reduced makeup water requirements and chemical treatment costs. Performance variability stems from cooling tower selection, with mechanical draft towers offering 15% greater water recovery but requiring higher maintenance than natural draft alternatives.

Engineering Advancements in Thermal Management Technology

Contemporary systems incorporate numerous innovations that enhance reliability under demanding operating conditions. Titanium-nickel alloy heat exchanger plates provide superior corrosion resistance against aggressive water chemistries while maintaining 98% thermal conductivity of pure copper. Variable frequency drives on circulating pumps adjust flow rates based on real-time heat load data, achieving 30% energy savings. Integrated sensor networks monitor critical parameters including chloride concentration (maintained below 50 ppm), pH stability (optimized at 8.0-9.2), and microbiological activity. Automated blowdown control maintains dissolved solids below 3,000 ppm, substantially reducing water waste. Hybrid tower designs that combine wet and dry cooling sections resolve the perennial water conservation versus efficiency trade-off, maintaining turbine backpressure within 2 kPa of optimal while cutting evaporation losses by 60%.

Manufacturer Capability Comparison

Choosing system suppliers requires evaluating engineering expertise against project-specific parameters:

| Vendor | Maximum Capacity | Material Options | Lead Times | Specialized Solutions |

|---|---|---|---|---|

| SPX Cooling | 850 MW | SS316L, Titanium | 26-34 weeks | Sea water cooling modules |

| BAC Scandinavia | 1,200 MW | Duplex Stainless, Copper-Nickel | 22-28 weeks | Zero-discharge systems |

| EVAPCO Systems | 650 MW | Admiralty Brass, AL-6XN | 18-24 weeks | Hybrid tower retrofits |

| GEA Heat Exchangers | 900 MW | Hastelloy, SMO 254 | 30-36 weeks | Fully automated CCW trains |

Material selection proves critical, with SMO 254 stainless steel offering superior pitting resistance at 60°C compared to conventional alternatives. System integrators now provide comprehensive design-build-maintain packages that include remote performance monitoring through IoT platforms.

Plant-Specific Configuration Engineering

Effective CCW deployment requires tailoring to each facility's operating profile. Combined cycle plants benefit from modular designs with multiple 45% capacity trains, maintaining operations during maintenance cycles. Coastal installations necessitate titanium-core heat exchangers and FRP piping to withstand chloride concentrations exceeding 15,000 ppm. Arid-region solutions incorporate air-cooled condensers paired with adiabatic coolers that reduce peak water consumption to just 5% of conventional wet towers. For brownfield sites, engineered retrofits focus on velocity optimization in existing piping networks, limiting flow rates to 2.4 m/s in carbon steel and 3.6 m/s in copper-nickel alloys to prevent erosion-corrosion. Advanced stress analysis ensures thermal expansion in 500-meter piping runs remains below 150 mm, preventing flange leakage without expensive expansion joints.

Operational Validation Through Field Implementation

Jebel Ali Phase 3 (UAE): Installation of hybrid cooling towers reduced freshwater demand to 0.48 m³/MWh while maintaining summer generation capacity. The integrated solution handled 2,200 MW thermal load with approach temperatures within 3°C of design specifications despite ambient conditions reaching 48°C. Flanders Power Station (Belgium): Retrofitted titanium plate heat exchangers resolved chronic tube failures in brackish cooling applications. Corrosion-related maintenance decreased 89% during the subsequent 24-month period while heat transfer coefficients stabilized at 4,800 W/m²°C ± 3%. Both installations demonstrate how modern systems resolve core challenges: chemical treatment costs decreased 55% at Jebel Ali while Flanders achieved 18-month ROI through extended equipment longevity and elimination of forced outages.

Sustaining Peak Performance in Closed Cooling Water Infrastructure

Proactive maintenance protocols ensure CCW systems meet designed lifespans exceeding thirty years. Quarterly water chemistry profiling tracks twenty-four parameters including inhibitor residuals (maintained at 40-60 ppm), microbial counts (controlled below 10,000 CFU/mL), and corrosion rates (target under 0.5 mpy). Eddy current testing of heat exchanger plates identifies fouling before thermal efficiency degrades beyond 10%. Mechanical integrity programs include hydrostatic testing at 1.5 times design pressure during biennial outages. Facilities implementing comprehensive management see auxiliary load consumption remain below 0.6% of generated output and unplanned turbine trips reduced by approximately 90% compared to plants with reactive maintenance approaches. These maintenance strategies transform cooling infrastructure from cost centers to value generators through sustained availability and optimized thermal efficiency.

(closed cooling water system in power plant)

FAQS on closed cooling water system in power plant

Q: What is the purpose of a closed cooling water system in a power plant?

A: A closed cooling water system circulates purified water to cool critical equipment, minimizing water consumption and contamination. It operates in a loop, reducing thermal discharge and environmental impact.

Q: What are the main types of cooling towers used in power plants?

A: The two primary types are natural draft (using convection) and mechanical draft (using fans). Hybrid designs combine both methods for efficiency in varying conditions.

Q: How does a thermal power plant cooling tower function?

A: It dissipates waste heat by transferring it from circulating water to the atmosphere via evaporation. This maintains optimal temperatures for the power cycle while conserving water resources.

Q: What distinguishes closed and open cooling systems in power plants?

A: Closed systems recycle water internally with minimal loss, while open systems continuously draw and discharge water. Closed systems prevent contamination but require advanced filtration.

Q: Why is maintenance crucial for closed cooling water systems?

A: Proper maintenance prevents corrosion, scaling, and microbial growth that reduce efficiency. Regular chemical treatment and component inspections ensure reliable heat exchange and system longevity.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China