We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Introduction to Air Conditioning Cooling Towers & Industry Trends

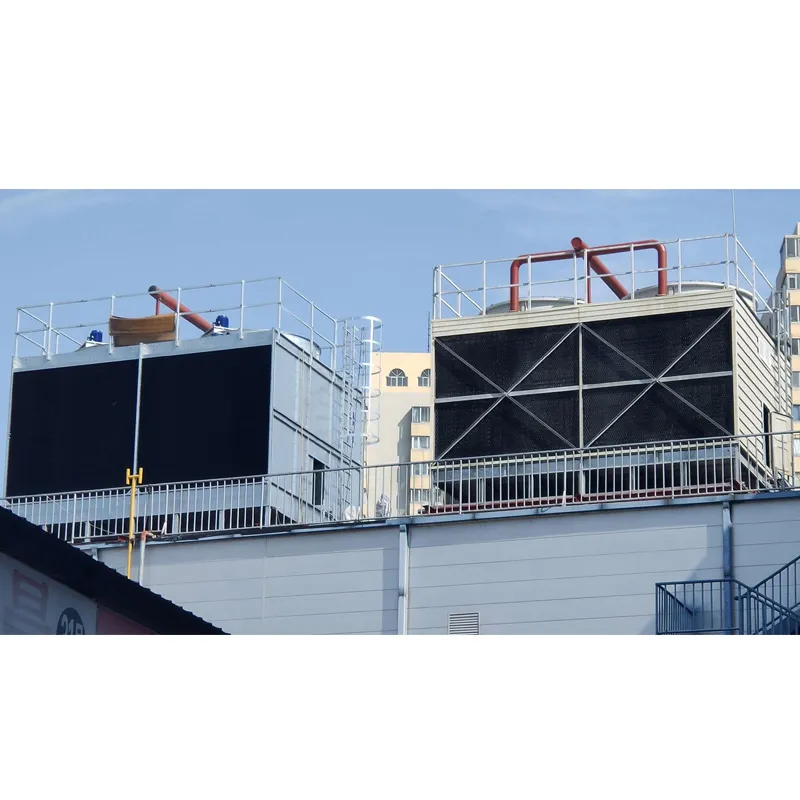

In large-scale commercial, industrial, and institutional facilities, efficient heat rejection is paramount for optimal operational performance and energy conservation. The air conditioning cooling tower serves as a critical component in HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration systems, facilitating the dissipation of waste heat from the chilled water system into the atmosphere. This process is integral to maintaining desired indoor temperatures and ensuring the longevity and efficiency of chilling equipment.

Current industry trends for cooling tower technology are heavily influenced by a global drive towards sustainability, energy efficiency, and operational resilience. Key trends include the adoption of advanced materials like Fiberglass Reinforced Polymer (FRP) for enhanced corrosion resistance and extended service life, as well as innovations in fan and motor technologies to minimize energy consumption and noise pollution. Furthermore, integration with smart building management systems (BMS) for predictive maintenance, real-time performance monitoring, and optimized control strategies is becoming standard. Modular designs are also gaining traction, offering scalability, ease of installation, and reduced downtime for maintenance or upgrades, addressing the complex demands of modern industrial infrastructure.

Technical Specifications and Parameters of a Modern Air Conditioning Cooling Tower

Understanding the intricate technical specifications is crucial for selecting the appropriate air conditioning cooling tower for a specific application. These units are designed with precision engineering to ensure optimal heat exchange. Core components typically include:

- Fill Media: Often PVC or polypropylene, designed with large surface areas to maximize contact between air and water, promoting evaporative cooling.

- Drift Eliminators: Crucial for minimizing water loss by capturing water droplets entrained in the airstream, typically made from PVC or FRP.

- Fan System: Axial or centrifugal fans, powered by highly efficient motors, responsible for drawing or pushing air through the tower.

- Water Distribution System: Consisting of spray nozzles or gravity-flow basins that evenly distribute hot water over the fill media.

- Cold Water Basin: Collects the cooled water before it is returned to the chiller or process.

- Struttura: Constructed from durable materials such as Fiberglass Reinforced Polymer (FRP), hot-dip galvanized steel, or stainless steel for longevity and corrosion resistance.

Critical operational parameters defining a cooling tower's performance include:

- Cooling Capacity: Measured in Tons of Refrigeration (TR) or kilowatts (kW), indicating the rate of heat removal.

- Flow Rate: The volume of water circulated through the tower, typically in Gallons Per Minute (GPM) or cubic meters per hour.

- Range: The temperature difference between the hot water entering and cold water leaving the tower.

- Approach: The temperature difference between the cold water leaving the tower and the wet-bulb temperature of the ambient air. A smaller approach indicates higher efficiency.

- Wet-Bulb Temperature: The most critical meteorological parameter influencing cooling tower performance, representing the lowest temperature an evaporative cooler can achieve.

Typical Product Specification Table: Counter-Flow FRP Cooling Tower

| Parametro | Value/Description |

|---|---|

| Cooling Capacity | 100-2000 TR (350-7000 kW) |

| Flow Rate | 300-6000 GPM (68-1363 m³/h) |

| Structure Material | FRP (Fiberglass Reinforced Polymer) |

| Supporto di riempimento | High-efficiency PVC film fill |

| Fan Type | Axial flow, low noise |

| Motor Efficiency | IE3/NEMA Premium Efficiency |

| Noise Level | < 70 dB(A) at 1m |

| Design Service Life | 20+ Years |

| Operating Weight | Varies by model (e.g., 5-50 tons) |

Manufacturing Process Flow of an Air Conditioning Cooling Tower

The production of a high-performance air conditioning cooling tower is a meticulous process, integrating advanced engineering with stringent quality control. Our manufacturing process ensures durability, efficiency, and reliability, adhering to international standards such as ISO 9001 for quality management and CTI (Cooling Technology Institute) for thermal performance.

1. Material Selection & Preparation

Careful selection of premium materials: high-grade Fiberglass Reinforced Polymer (FRP) resins and glass fibers for casing, UV-stabilized PVC for fill media and drift eliminators, hot-dip galvanized or stainless steel for structural frames, and corrosion-resistant alloys for mechanical components. Quality checks ensure raw material compliance with ASTM and EN standards.

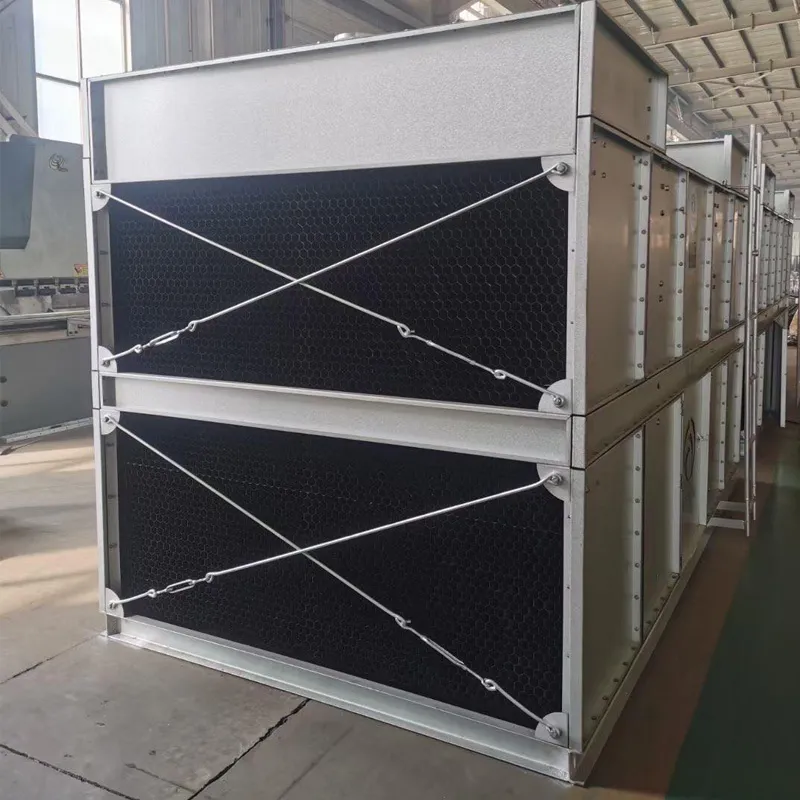

2. FRP Fabrication & Component Manufacturing

FRP casing panels are produced using advanced hand lay-up or spray-up techniques, followed by curing in controlled environments. Steel structural elements undergo precision cutting, forging, and welding, then hot-dip galvanization (per ISO 1461) or stainless steel passivation for maximum corrosion protection. Fan blades and water distribution nozzles are manufactured via precision injection molding or CNC machining.

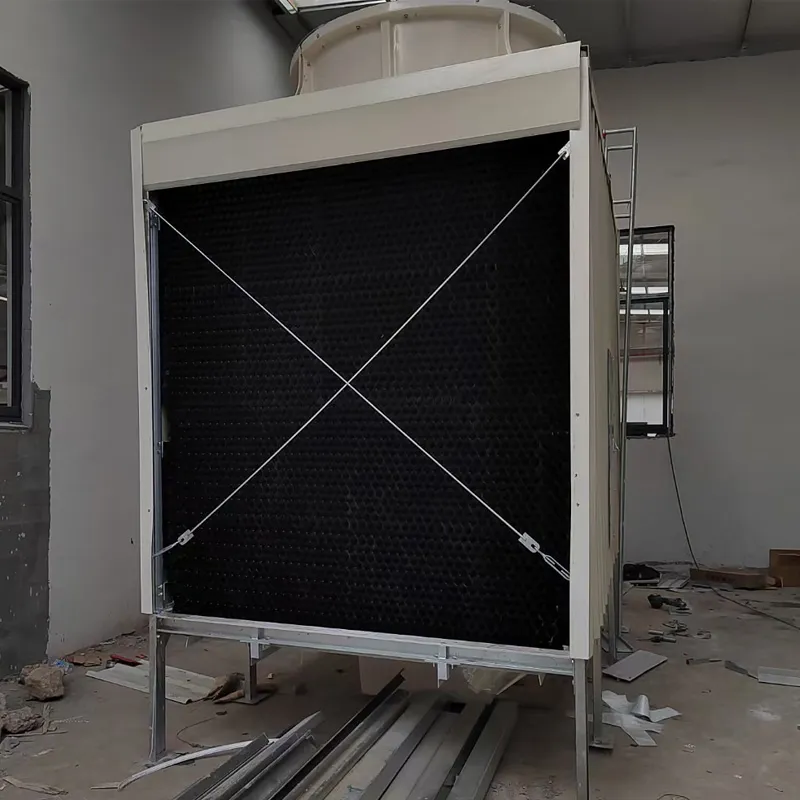

3. Assembly & Installation Pre-Checks

Individual components are assembled by skilled technicians following detailed engineering drawings. This stage includes precise alignment of the fan stack, installation of fill media, drift eliminators, and the water distribution system. All fasteners and internal components are checked for proper torque and fit.

4. Quality Control & Performance Testing

Each cooling tower undergoes rigorous multi-stage quality control. This includes visual inspections, dimensional checks, hydrostatic testing of basins, motor and fan vibration analysis, and comprehensive thermal performance testing in our CTI-certified test facility (if applicable to model line). This ensures compliance with design specifications and operational efficiency.

5. Packaging & Logistics

Upon successful completion of all tests, units are carefully packaged for shipment, either as fully assembled modules or in knock-down format for large-scale projects. Protective measures are employed to prevent damage during transit to ensure the product arrives at the site in pristine condition.

Our commitment to quality ensures that every air conditioning cooling tower is engineered for a design service life typically exceeding 20 years, even in demanding industrial environments. These towers are specifically designed for robust performance in target industries such as petrochemical, metallurgy, power generation, data centers, and various water supply & drainage systems, demonstrating significant advantages in energy saving and corrosion resistance due to superior material selection and optimized aerodynamic design.

Key Technical Advantages and Operational Benefits

Modern air conditioning cooling tower systems offer a suite of technical advantages that translate into significant operational benefits for industrial and commercial users. These benefits extend beyond mere heat rejection to encompass long-term economic and environmental sustainability.

- Superior Energy Efficiency: Optimized fan designs, high-efficiency motors (e.g., IE3/NEMA Premium), and advanced fill media ensure minimal power consumption for maximum heat transfer. This results in reduced operating costs and a lower carbon footprint, often exceeding ASHRAE 90.1 energy performance standards.

- Exceptional Corrosion Resistance: Utilizing materials like FRP for structural components, basins, and casings provides unparalleled resistance to corrosive chemicals, atmospheric degradation, and biological fouling. This significantly extends the service life, especially in harsh industrial environments such as chemical plants or coastal regions, far surpassing traditional galvanized steel options.

- Reduced Maintenance Requirements: The inherent durability of FRP, coupled with easily accessible internal components and robust mechanical systems, translates into fewer breakdowns and simplified maintenance routines. This minimizes operational downtime and associated labor costs.

- Low Noise Operation: Advanced fan blade profiles, noise attenuation packages, and vibration dampening mounts are engineered to meet stringent noise regulations, making these towers suitable for sensitive urban or residential proximity installations.

- Water Conservation: High-efficiency drift eliminators reduce water loss due to entrainment to as low as 0.001% of the circulating water flow, while advanced control systems can optimize blowdown rates, contributing to significant water savings and lower utility bills.

- Modular and Scalable Design: Many systems are designed with modularity in mind, allowing for easy expansion of cooling capacity as demand grows. This flexibility reduces initial capital expenditure and simplifies future upgrades.

These advantages collectively ensure that investing in a high-quality air conditioning cooling tower is a strategic decision that delivers long-term value, reliability, and environmental responsibility.

Diverse Application Scenarios

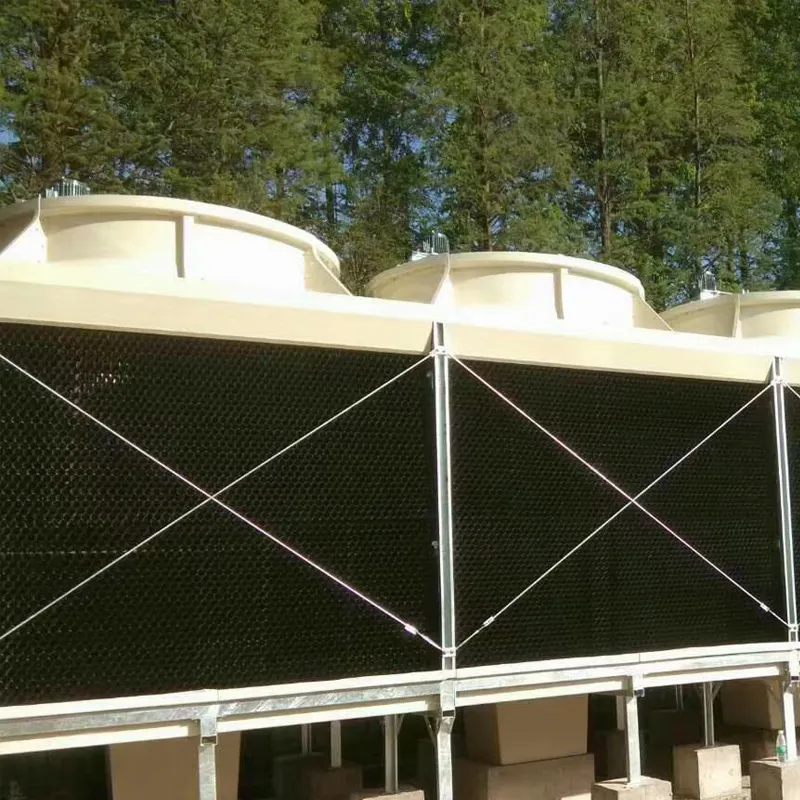

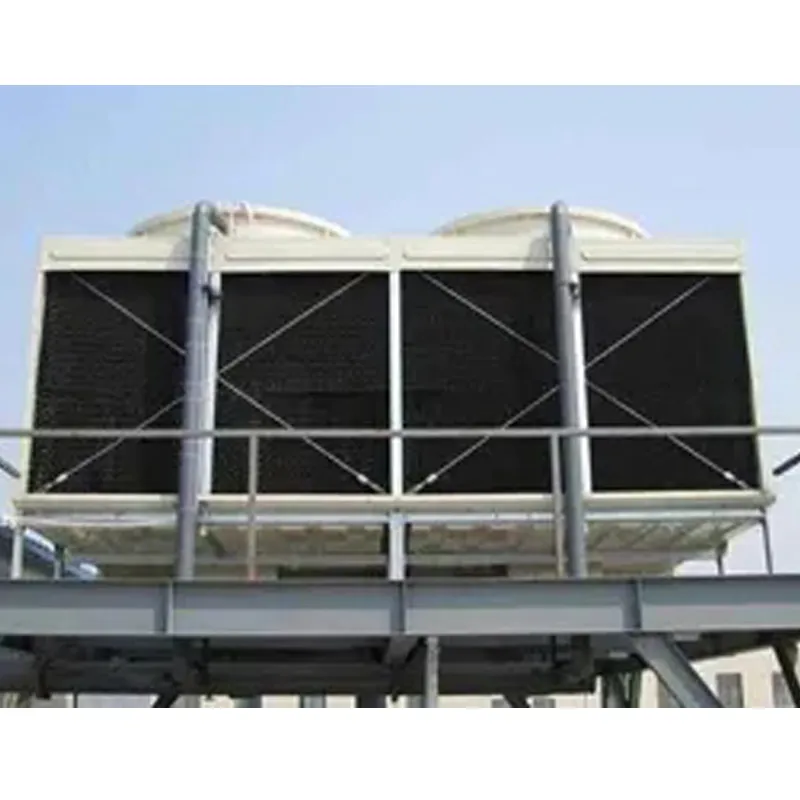

The versatility and efficiency of the air conditioning cooling tower make it an indispensable asset across a broad spectrum of industries and commercial applications. Its primary role in heat rejection is critical for maintaining optimal operating temperatures in various processes and environments.

Commercial Buildings & HVAC Systems

In large commercial facilities such as office towers, hospitals, shopping malls, and educational institutions, cooling towers are the backbone of central air conditioning systems. They efficiently cool the condenser water from chillers, ensuring comfortable indoor climates and minimizing the energy consumption of HVAC infrastructure. Data centers, a rapidly growing sector, rely heavily on precise and continuous cooling provided by these systems to prevent equipment overheating and ensure uninterrupted operation.

Industrial Processes & Refrigeration Systems

Industrial applications demand robust and reliable cooling solutions. In the petrochemical industry, cooling towers are vital for chilling process water used in distillation, reaction vessels, and heat exchangers. Metallurgy plants use them to cool furnaces, rolling mills, and casting equipment. Power generation facilities, including thermal and nuclear plants, employ large-scale cooling towers for condensing steam. Food and beverage processing, pharmaceuticals, and manufacturing industries utilize these towers for precise temperature control in production lines and refrigeration systems, ensuring product quality and safety. The ability of a properly specified cooling tower in air conditioning system to handle variable loads and harsh water quality is paramount in these settings.

Specialized Applications

Beyond conventional uses, advanced cooling tower solutions are deployed in district cooling plants, which provide centralized chilled water to multiple buildings, and in highly sensitive environments requiring ultra-low noise or specific material compatibility. Our solutions cater to water supply and drainage systems requiring robust heat dissipation and energy recovery.

Customized Solutions for AC Cooling Tower Systems

Recognizing that no two projects are identical, we specialize in providing highly customized solutions for every ac cooling tower system. Our engineering team works closely with clients to develop configurations that precisely match their unique operational requirements, spatial constraints, and environmental conditions.

- Capacity & Configuration Matching: From compact units for small commercial buildings to large-scale, multi-cell industrial installations, we custom-design capacities to meet exact heat load demands. Both counter-flow and cross-flow configurations are available, optimized for specific footprint, fan power, and maintenance access needs.

- Material Selection: While FRP is our standard for its superior corrosion resistance and longevity, we offer material alternatives for specific applications, including various grades of stainless steel (304, 316) for extreme chemical resistance or specific regulatory compliance.

- Noise Attenuation Packages: For installations in noise-sensitive areas, customized low-noise fans, acoustic enclosures, and sound-dampening panels can be integrated to achieve desired decibel levels, often below 60 dB(A).

- Advanced Water Treatment & Filtration Integration: We can incorporate advanced water filtration systems (e.g., side-stream filters, automatic backwash filters) and chemical dosing systems to manage water quality, reduce scaling and biological growth, and minimize blowdown, thereby extending the life of the cooling tower and associated equipment.

- Smart Controls & Automation: Integration with Building Management Systems (BMS) and advanced PLC-based control panels allows for remote monitoring, variable frequency drive (VFD) control for fan motors, real-time data acquisition, and optimized energy usage based on ambient conditions and load.

- Seismic & Wind Load Design: For installations in regions prone to seismic activity or high wind loads, our structural designs are engineered to meet specific local building codes and standards (e.g., ASCE 7), ensuring structural integrity and safety.

Our approach to customization ensures that each client receives a cooling solution that is not only highly efficient and reliable but also perfectly aligned with their long-term operational and environmental objectives.

Vendor Comparison: Evaluating Cooling Tower AC Units

When selecting cooling tower ac units, a thorough vendor comparison is essential to ensure long-term value, performance, and reliability. Key factors differentiate leading manufacturers and should be carefully evaluated by B2B decision-makers.

Key Comparison Criteria:

- Material Quality and Construction: Evaluate the longevity and corrosion resistance of the materials used (e.g., FRP vs. galvanized steel vs. stainless steel). FRP offers superior durability in aggressive chemical environments.

- Thermal Performance & Efficiency: Certifications such as CTI (Cooling Technology Institute) are crucial. Compare energy consumption (kW/TR), approach, and range capabilities under specified conditions.

- Total Cost of Ownership (TCO): Beyond initial purchase price, consider long-term factors such as energy consumption, maintenance costs, expected service life, and water treatment expenses.

- Customization and Flexibility: Assess the vendor's ability to provide tailored solutions for specific project requirements, including capacity, footprint, noise levels, and integration with existing systems.

- After-Sales Support & Warranty: A robust warranty, readily available spare parts, and comprehensive technical support are vital for minimizing downtime and ensuring operational continuity.

- Certifications and Authoritativeness: Look for ISO certifications, industry affiliations, and a track record of successful installations.

Comparison Table: FRP Cooling Tower vs. Galvanized Steel Cooling Tower

| Caratteristica | FRP Cooling Tower (Our Offering) | Galvanized Steel Cooling Tower (Typical) |

|---|---|---|

| Resistenza alla corrosione | Excellent; resistant to chemicals, acids, alkalis, and atmospheric corrosion. | Good initially, but galvanization can degrade, leading to rust, especially at welds or in aggressive water. |

| Service Life | 20+ years, even in harsh conditions. | 10-15 years, requiring regular maintenance and protective coatings. |

| Manutenzione | Low; no painting or rust treatment required. Easy to clean. | Higher; requires periodic inspection for corrosion, repainting, and specialized water treatment to prevent scale and rust. |

| Peso | Lighter, reducing structural load on buildings and simplifying installation. | Heavier, potentially requiring stronger support structures. |

| Energy Efficiency | Optimized designs with advanced fill media and high-efficiency fans. | Can be efficient, but older designs may lag newer FRP counterparts. |

| Initial Cost | Potentially higher, but justified by lower TCO. | Often lower, but TCO can be higher due to maintenance and shorter life. |

Application Case Studies & Customer Experience

Our commitment to delivering high-performance cooling tower in refrigeration system solutions is best demonstrated through real-world application case studies and direct customer feedback. These examples highlight the tangible benefits and robust reliability of our engineered systems.

Case Study 1: Large-Scale Petrochemical Plant

Challenge: An existing aging cooling tower system at a major petrochemical facility faced severe corrosion issues, leading to frequent downtime, high maintenance costs, and reduced cooling efficiency, impacting critical production processes.

Solution: We designed and supplied a custom-engineered, multi-cell FRP cooling tower in refrigeration system with enhanced corrosion resistance and high-efficiency fill media. The modular design facilitated faster installation during a planned shutdown, minimizing disruption.

Results & Feedback: Post-installation, the plant reported a 15% improvement in chiller efficiency due to consistent cold water supply, a 60% reduction in annual maintenance expenditure related to corrosion, and zero unplanned downtime attributed to the cooling system in the first two years of operation. The plant manager praised the "unmatched durability and significantly lower operational headaches."

Case Study 2: Tier 4 Data Center Cooling

Challenge: A new Tier 4 data center required an extremely reliable, energy-efficient cooling solution with ultra-low noise emissions, given its urban location. Continuous operation and precise temperature control were paramount.

Solution: We provided a series of advanced, low-noise cooling tower in refrigeration system units equipped with variable frequency drives (VFDs) for fan speed control and specialized acoustic attenuation packages. The system was integrated with the data center's advanced BMS for real-time optimization.

Results & Feedback: The cooling system achieved a measured PUE (Power Usage Effectiveness) of 1.25, significantly contributing to the data center's energy efficiency goals. Noise levels at the property line were below ambient city noise, satisfying local regulations. The client commented on the "seamless integration and the exceptional quiet operation, which were critical for our site."

These case studies underscore our capability to deliver robust, tailored, and high-performance cooling solutions that meet the stringent requirements of diverse B2B environments, ensuring client satisfaction and operational excellence.

Authoritativeness, Certifications, and Industry Recognition

Our position as a leading provider of air conditioning cooling tower solutions is underpinned by a steadfast commitment to quality, industry compliance, and proven expertise. We uphold the highest standards, reflected in our comprehensive certifications and strong industry partnerships.

- ISO Certifications: We operate under ISO 9001:2015 for Quality Management Systems, ensuring consistent product quality and customer satisfaction; ISO 14001:2015 for Environmental Management Systems, demonstrating our commitment to sustainable practices; and ISO 45001:2018 for Occupational Health and Safety, guaranteeing a safe working environment.

- CTI Certification: Our cooling towers are designed and manufactured to meet or exceed the thermal performance standards set by the Cooling Technology Institute (CTI). Many of our models are CTI certified, providing independent verification of their performance capabilities and ensuring clients receive the specified cooling capacity.

- Years of Service & Experience: With over two decades of specialized experience in cooling tower design, manufacturing, and installation, our deep industry knowledge allows us to deliver optimized solutions for even the most complex projects.

- Strategic Partnerships: We collaborate with renowned engineering firms, general contractors, and technology providers globally, integrating our cooling solutions into large-scale infrastructure projects and ensuring seamless project execution.

- Rigorous Testing & Data Validation: All products undergo comprehensive in-house testing, including hydrostatic pressure tests, material stress tests, and performance validation tests using advanced instrumentation. Our test data is meticulously recorded and available for client review, ensuring complete transparency.

This dedication to certified quality and proven performance ensures that our clients invest in not just a product, but a reliable, efficient, and authoritative cooling solution.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of your air conditioning cooling tower systems?

A1: Our FRP-constructed air conditioning cooling tower units are engineered for a design service life of 20 years or more, assuming proper installation and adherence to recommended maintenance schedules. The inherent corrosion resistance of FRP significantly contributes to this extended lifespan compared to traditional materials.

Q2: How often should a cooling tower undergo maintenance?

A2: Regular maintenance is crucial. We recommend daily visual checks, monthly inspections of key components (e.g., fill, nozzles, fans), and annual comprehensive overhauls. Specific schedules may vary based on water quality, operational load, and environmental conditions. Our service team can provide tailored maintenance plans.

Q3: What factors contribute most to cooling tower efficiency?

A3: Key factors include the design of the fill media, fan and motor efficiency, water distribution uniformity, and control system optimization. A well-designed tower minimizes fan power while maximizing heat transfer, and operates efficiently under varying wet-bulb temperatures and heat loads.

Q4: How do you minimize water consumption in your cooling towers?

A4: We incorporate high-efficiency drift eliminators that reduce water loss due to evaporation to negligible levels. Additionally, intelligent control systems optimize cycles of concentration and blowdown, further conserving water without compromising performance or water quality.

Q5: What environmental considerations are addressed in your cooling tower designs?

A5: Our designs focus on energy efficiency (reducing greenhouse gas emissions), water conservation (minimizing depletion of freshwater resources), and low noise operation (reducing sound pollution). We also prioritize the use of recyclable materials where feasible.

Lead Time, Warranty, and After-Sales Support

We understand the critical importance of timely delivery, comprehensive warranties, and responsive after-sales support for B2B clients. Our commitments are designed to provide peace of mind and ensure the uninterrupted performance of your cooling infrastructure.

Lead Time & Fulfillment

Typical lead times for standard air conditioning cooling tower models range from 6 to 10 weeks from order confirmation to ex-works dispatch, depending on complexity and current production schedules. For highly customized or large-scale industrial projects, lead times will be specified in the project proposal, reflecting the tailored engineering and manufacturing processes involved. We maintain efficient logistics channels to ensure prompt and secure delivery to project sites worldwide.

Warranty Commitments

We offer a comprehensive warranty package for our air conditioning cooling tower products. This typically includes a 1-year warranty on all mechanical and electrical components from the date of commissioning or 18 months from shipment (whichever comes first), and an extended 5-year warranty on the FRP structure against material and manufacturing defects. Detailed warranty terms and conditions are provided with each quotation and purchase agreement.

Dedicated After-Sales Support

Our commitment extends beyond delivery. We provide robust after-sales support to ensure the continuous and efficient operation of your cooling towers.

- Technical Assistance: Our team of expert engineers is available for remote and, if necessary, on-site technical support, troubleshooting, and performance optimization.

- Spare Parts Availability: We maintain a comprehensive inventory of genuine spare parts to minimize downtime and ensure rapid repairs or replacements.

- Training Services: We offer operational and maintenance training for your technical staff, empowering them with the knowledge to effectively manage and maintain the cooling tower system.

- On-Site Service: For complex issues or scheduled preventive maintenance, our skilled field service technicians are available for on-site interventions.

Conclusione

The modern air conditioning cooling tower is an indispensable asset for any large-scale facility requiring efficient and reliable heat rejection. With advancements in materials like FRP, enhanced energy efficiency, intelligent controls, and modular designs, these systems are more robust, sustainable, and adaptable than ever before. Choosing a trusted partner with proven expertise, comprehensive certifications, and a strong commitment to after-sales support ensures optimal performance and a lower total cost of ownership throughout the system's extended lifespan. Our dedication to engineering excellence and customer satisfaction positions us as the preferred choice for advanced cooling solutions across diverse industrial and commercial applications.

References

- Cooling Technology Institute (CTI). "About CTI and Its Standards." www.cti.org

- ASHRAE Standard 90.1. "Energy Standard for Buildings Except Low-Rise Residential Buildings." www.ashrae.org

- International Organization for Standardization (ISO). "ISO 9001:2015 Quality management systems." www.iso.org

- American Society of Mechanical Engineers (ASME). "Boiler and Pressure Vessel Code." www.asme.org

- Environmental Protection Agency (EPA). "WaterSense at Work: Best Management Practices for Commercial and Institutional Facilities." www.epa.gov

Prev Questo è il primo articolo

Indirizzo

20 Xingyuan South Street, contea di Zaoqiang, città di Hengshui, provincia di Hebei, Cina