We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

1.How It Works

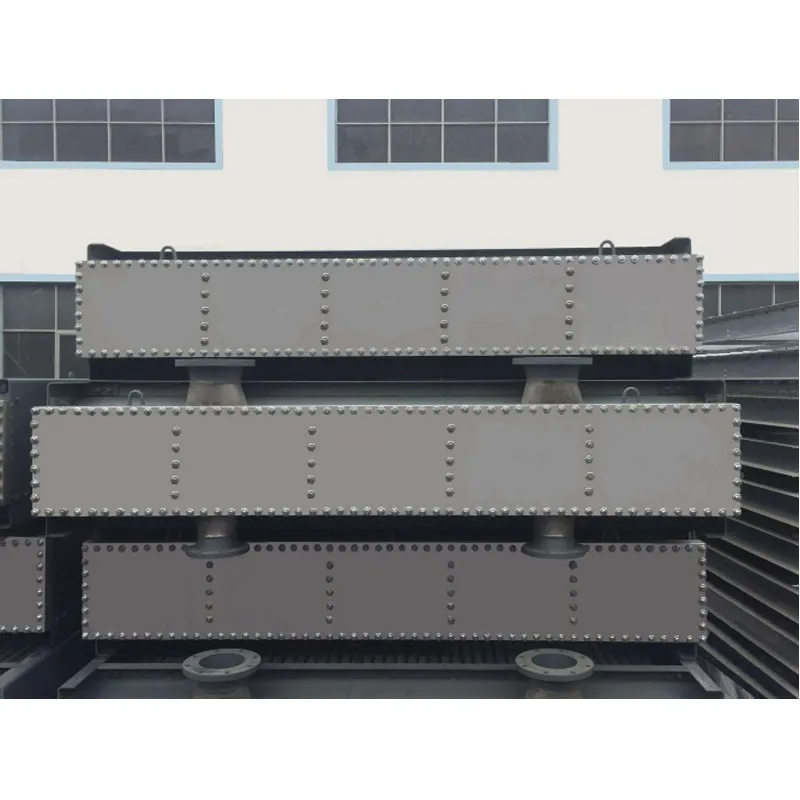

The Air Cooler utilizes forced air convection and finned-tube heat exchange technology to dissipate heat from fluids:

Heat Transfer: High-temperature media (water/oil/gas) flow through internal tubes, transferring heat to fin surfaces via conduction.

Air Forced Convection: Axial fans drive ambient air across finned tubes, absorbing heat and discharging it to the atmosphere.

Fin Optimization: Aluminum/copper fins increase heat transfer area by 10-24x, compensating for air's low specific heat capacity.

Smart Control: Adjustable louvers and variable-speed fans maintain outlet temperature stability (±1.5℃).

2.Key Advantages

Water-Free Operation

100% water saving vs. traditional cooling systems, saving 5,000+ tons annually.

Zero wastewater discharge, compliant with ISO 14001 standards.

Energy Efficiency

Low-noise axial fans (≤65dB) and VFD control reduce energy consumption by 40%.

Finned tubes achieve heat transfer coefficients of 300-800W/m²·℃, boosting efficiency by 30%.

Industrial Durability

Hot-dip galvanized steel/316L stainless steel tubes resist corrosion for 15+ years; zinc-plated or PP housing ensures weather resistance.

Modular design enables parallel operation without downtime.

Multi-Scenario Adaptability

Operates from -30℃ to 120℃, with anti-freeze (Arctic) or high-temperature (metallurgy) models.

Compatible with water, oil, ammonia, and refrigerants (up to 69MPa).

Cost-Effectiveness

Saves $500,000+ annually for 3000m³/h systems, with ROI within 2 years.

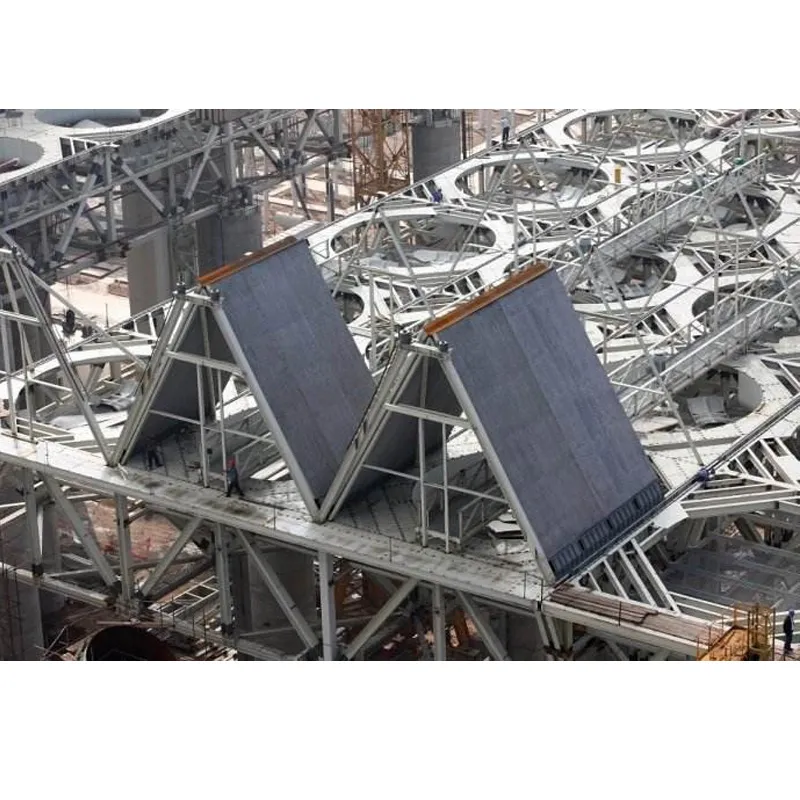

3.Applications

Oil & Gas: Refinery vapor condensation, reactor cooling (e.g., hydrogenation), lubricant temperature control.

Power Generation: Gas turbine inlet cooling, hydrogen cooling for generators, nuclear plant backup.

Data Centers: Indirect free cooling reduces PUE from 1.6 to 1.3.

Manufacturing: Mold cooling for injection molding, hydraulic system cooling in steel casting.

New Energy: PV polysilicon tail gas cooling, lithium battery roller temperature control.

Technical Specifications

ParameterSpecificationSourceMedia CompatibilityWater/Oil/NH3/R134aHeat Transfer Rate300-800W/m²·℃Noise (1m distance)≤65dB (≤55dB in Night Mode)Fan Power0.37-1.5kW (VFD Adjustable)Pressure Rating0-30MPa (Customizable)Protection ClassIP55 (Dust/Water Resistance)

4.Service Commitment

Global Warranty: 12-month coverage with lifetime support for core components.

IoT Monitoring: Optional real-time analytics for energy use, temperature, and fault alerts.

24/7 Support: On-site engineers within 48 hours, custom retrofit solutions.

Apa yang Pelanggan Kami Katakan Tentang Kami

/home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1344/article-products.php on line 375

/home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1344/article-products.php on line 375Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1344/article-products.php on line 375

" title="

Warning: Undefined array key "array_faq_common_pro_List_title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1344/article-products.php on line 375

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1344/article-products.php on line 375

">

Alamat

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China