We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

Understanding the nuances of industrial cooling systems is critical for optimizing energy efficiency and operational performance. This blog explores the mechanics, applications, and innovations in cooling ponds, spray ponds, and cooling towers, with a focus on counter-flow and cross-flow designs. Below is a structured overview of the content:

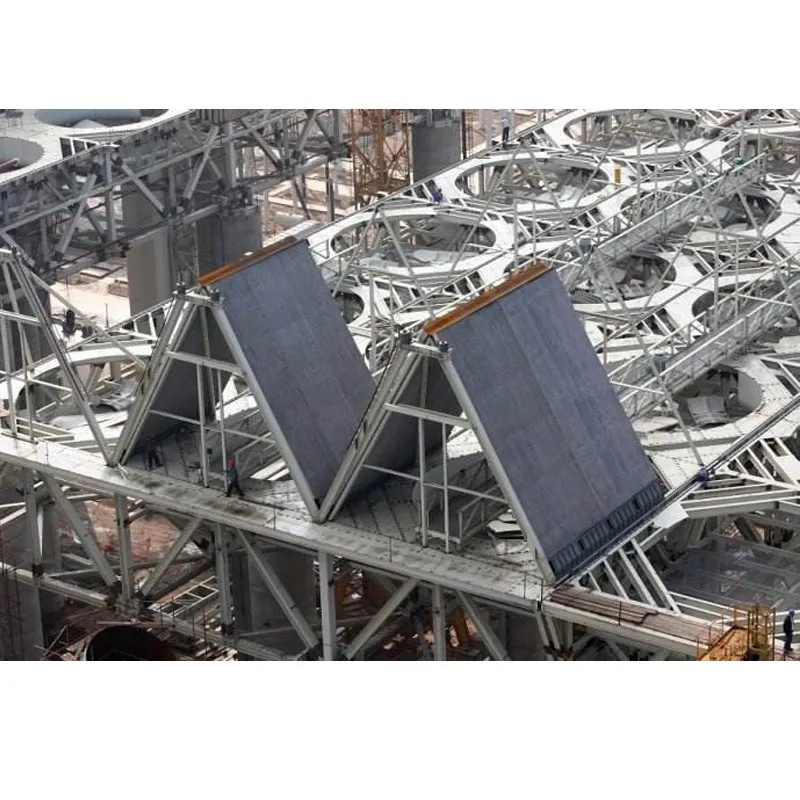

(cooling pond and cooling tower)

Cooling Pond and Cooling Tower Systems: Foundational Principles

Cooling ponds and towers are integral to thermal management in industries like power generation, manufacturing, and HVAC. While cooling ponds rely on natural evaporation from large water surfaces, cooling towers use forced airflow to accelerate heat dissipation. Spray ponds enhance efficiency by dispersing water through nozzles, combining aspects of both systems. Counter-flow cooling towers direct air upward against falling water, maximizing contact time, whereas cross-flow designs allow air to move horizontally, reducing pump energy. Understanding these differences ensures optimal system selection.

Technical Superiority in Heat Dissipation

Modern cooling systems leverage advanced materials and engineering to outperform traditional methods. For instance, fiber-reinforced polymers (FRPs) in tower construction reduce corrosion by 40% compared to steel. Variable-frequency drives (VFDs) cut energy consumption by 15–25%, while hybrid designs integrating spray and tower mechanisms achieve 90% thermal efficiency. These innovations address rising demands for sustainability, particularly in regions with stringent environmental regulations.

Manufacturer Comparison: Performance and Reliability

| Manufacturer | Flow Rate (m³/h) | Energy Use (kW) | Material | Warranty (Years) |

|---|---|---|---|---|

| Company A | 1,200 | 85 | FRP | 10 |

| Company B | 950 | 72 | Stainless Steel | 7 |

| Company C | 1,500 | 105 | Galvanized Steel | 5 |

Data highlights Company A’s dominance in high-capacity FRP-based systems, whereas Company B prioritizes energy efficiency. Material choice directly impacts longevity, with FRP offering superior resistance to chemical degradation.

Tailored Solutions for Diverse Industries

Customization is vital for adapting cooling systems to unique operational environments. For example, power plants require corrosion-resistant coatings to handle high-temperature discharge, while data centers prioritize compact, noise-reduced towers. Modular designs enable scalability, allowing facilities to expand capacity by 30–50% without structural overhauls. Advanced control systems also permit remote monitoring, slashing maintenance costs by up to 20%.

Case Study: Efficiency Gains in Automotive Manufacturing

A European automotive plant reduced cooling costs by 18% after replacing its cross-flow tower with a counter-flow system. The upgrade minimized water waste by 22% and cut downtime through predictive maintenance algorithms. This case underscores the importance of aligning system design with operational KPIs.

Innovations Shaping Cooling Pond and Cooling Tower Development

Emerging technologies like AI-driven airflow optimization and graphene-coated heat exchangers promise to revolutionize cooling efficiency. Solar-assisted towers, which integrate photovoltaic panels, reduce grid dependence by 35%, aligning with global decarbonization goals. As industries face stricter emissions standards, these advancements will define the next generation of thermal management systems.

(cooling pond and cooling tower)

FAQS on cooling pond and cooling tower

Q: What is the main difference between a cooling pond and a cooling tower?

A: A cooling pond relies on natural evaporation from a large water surface, while a cooling tower uses mechanical airflow to enhance heat dissipation. Cooling ponds require more space and are passive systems, whereas cooling towers are compact and active. They are chosen based on efficiency and site constraints.

Q: How do spray ponds differ from cooling towers in design and function?

A: Spray ponds use nozzles to disperse water into the air for cooling, while cooling towers employ fill media and fans to maximize air-water contact. Spray ponds are simpler but less efficient than cooling towers. Both aim to reject heat but differ in energy use and scalability.

Q: What distinguishes counter-flow from cross-flow cooling towers?

A: In counter-flow towers, air moves upward against falling water, maximizing heat exchange. Cross-flow towers have air moving horizontally across downward-flowing water, offering lower pressure drop. Counter-flow designs are typically more efficient but taller, while cross-flow towers are wider and easier to maintain.

Q: What are the advantages of cooling towers over cooling ponds?

A: Cooling towers occupy less space, provide faster heat rejection, and perform better in limited-area environments. They also offer precise temperature control compared to cooling ponds. However, they require more energy and maintenance than passive pond systems.

Q: When would a cooling pond be preferred over a cooling tower?

A: Cooling ponds are ideal where land availability and low operational costs outweigh efficiency needs, such as in rural power plants. They suit applications with minimal space constraints and lower cooling demands. Environmental regulations and water conservation goals may also influence this choice.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China